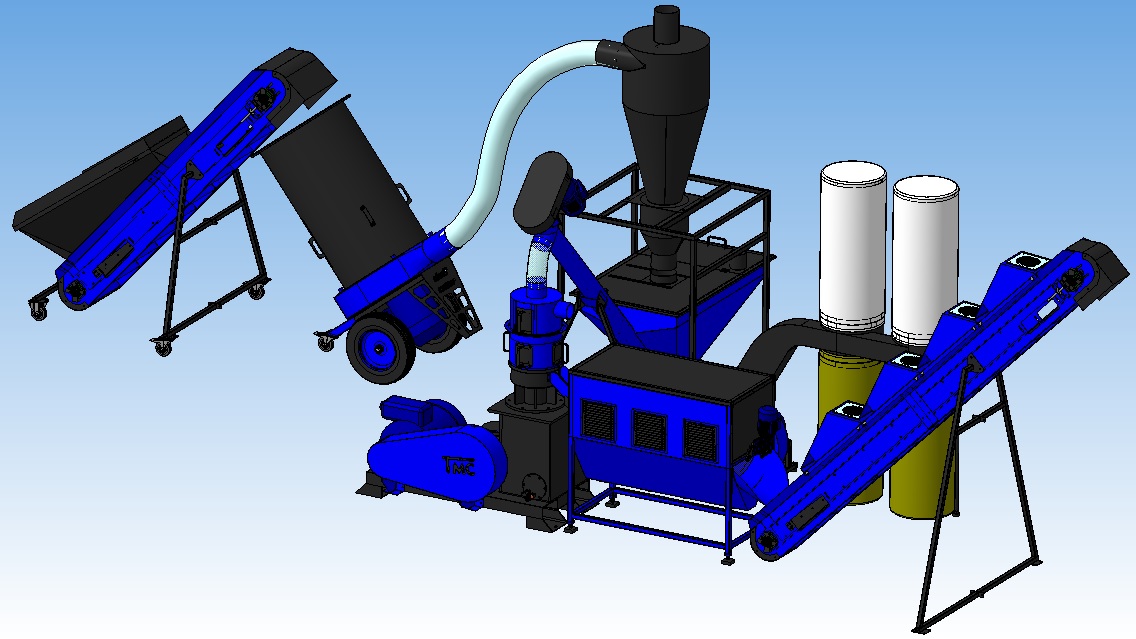

Granulation Line LDG-3000 (KOMBI)

Available Options

- Product Code: LDG-3000-KOMBI

Description

The LDG-3000 KOMBI pellet and feed production line from TechnoMaszBud, based on the PRIME-300 pelleting machine, is designed for producing pellets with a diameter of 2 mm to 8 mm from various types of raw materials, including sawdust, shavings, dust, and other waste from the woodworking and sawmill industries. The device can also be used for animal feed production.

YOU CAN TEST THIS MACHINE WITH YOUR RAW MATERIAL AT OUR WAREHOUSE!

Video: Pine sawdust pelleting line | Capacity up to 400 kg/h:

This equipment differs from the LDG-2000 KOMBI granulation line series primarily by the use of a more powerful pelleting machine. The granulation line can be used both for pellet and compound feed production — for your own needs or for commercial activities.

For your convenience, we not only help choose the right line to meet your requirements, but we also provide assistance with installation, startup, and achieving the expected results!

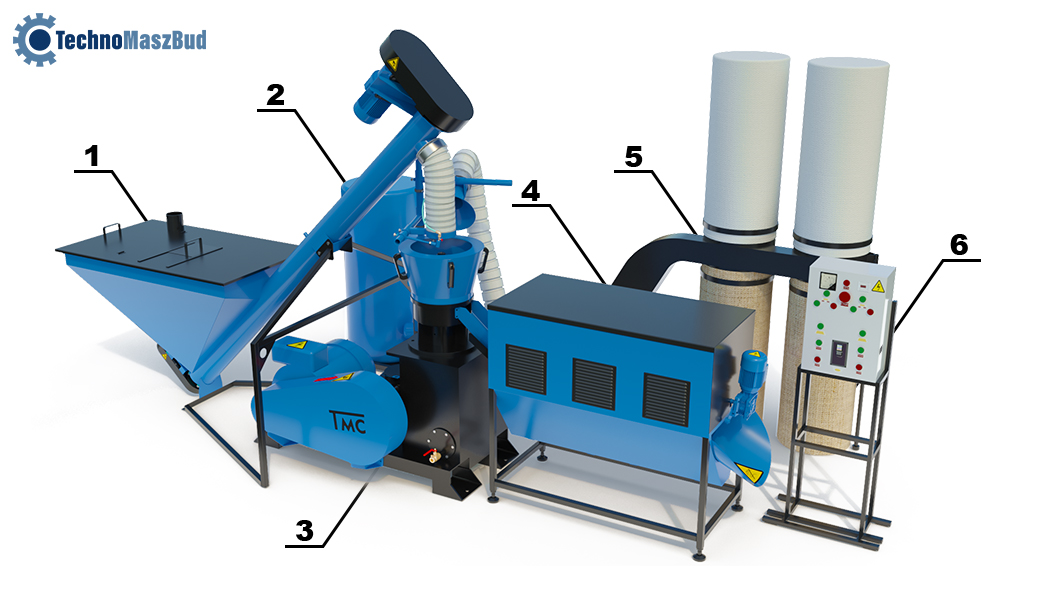

The line includes:

1. Screw Feeder PS-200 (1.5 kW) – with smooth feed rate adjustment via frequency inverter.

2. Moisturizing system (0.37 kW) – valve, pump, 100-liter water tank, nozzle; the system is connected to a stand above the working area, allowing you to add the required, measured amount of moisture during granulation.

3. PRIME-300 Pelleting Machine – suitable motors can be installed for different types of raw materials: for feed – 30 kW, for pellets – 22 kW.

4. Granule/Pellet Calibrator-Cooler KC-100 (0.12 kW) – provides additional product cooling and removes dust and crumbs with a special drum.

5. Closed Extraction System SO-2 (1.5 kW) – this device uses a fan to provide the airflow necessary to cool the pellets and collect calibrated raw material remnants and dust into containers (bags mounted on the device).

6. Control panel – intuitive operation, facilitating work. Small size and built-in automation cooling system make the control panel reliable and convenient to install near the production line. The panel includes an ammeter and thermal protection for each motor in the line

Belt conveyor is not included in the set!

Cables for connecting the line are not included in the set

Video: Throughput measurement on oak sawdust | LDG-3000 KOMBI pellet line:

LDG-3000 KOMBI Pellet Production Line Performance:

- wood waste – up to 350 kg/h,

- straw – up to 250 kg/h,

- feed – up to 700 kg/h,

- sunflower husks – up to 350 kg/h.

It is crucial to maintain the proper particle size and moisture level of the processed raw materials.

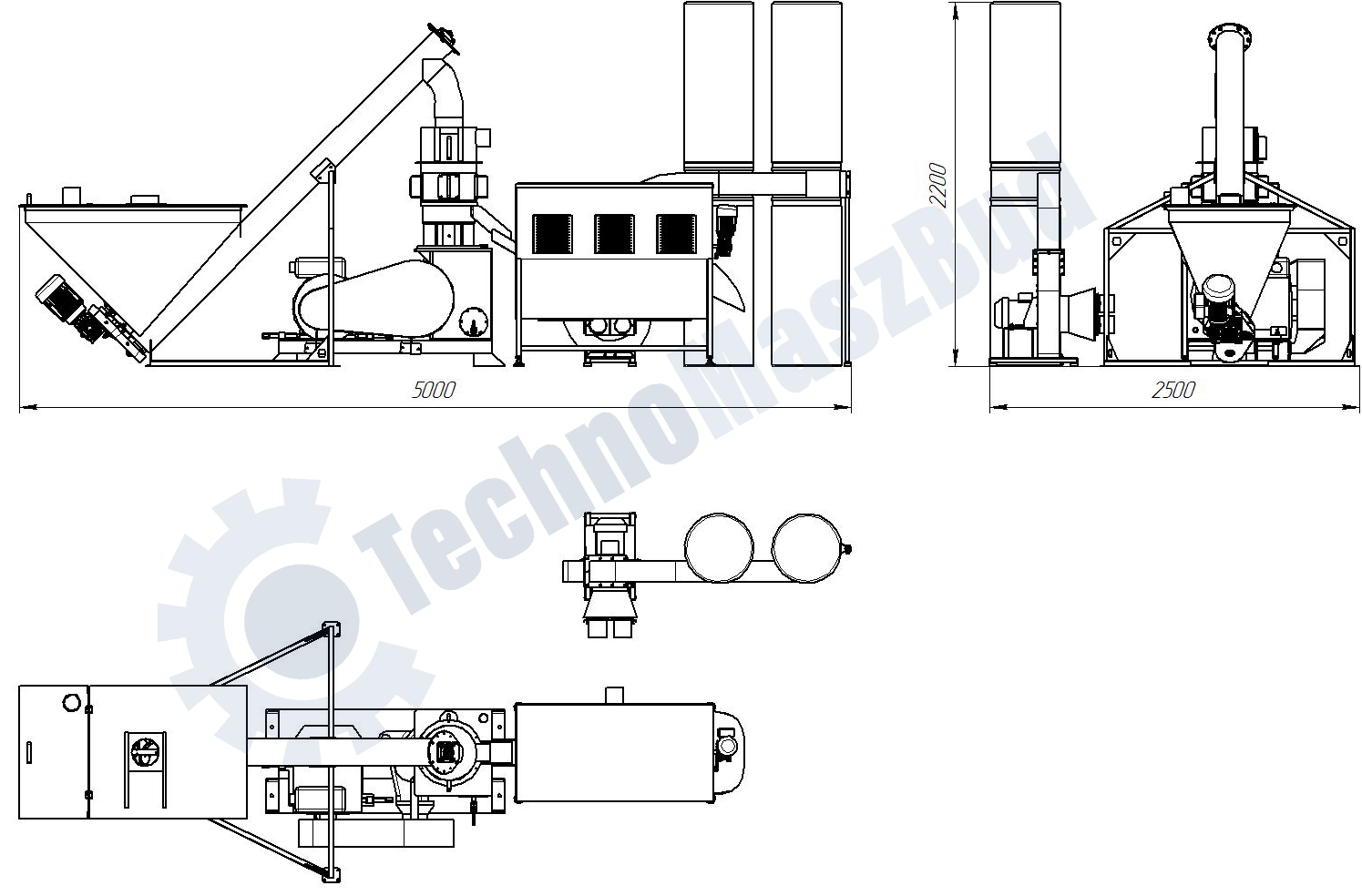

Technical drawing:

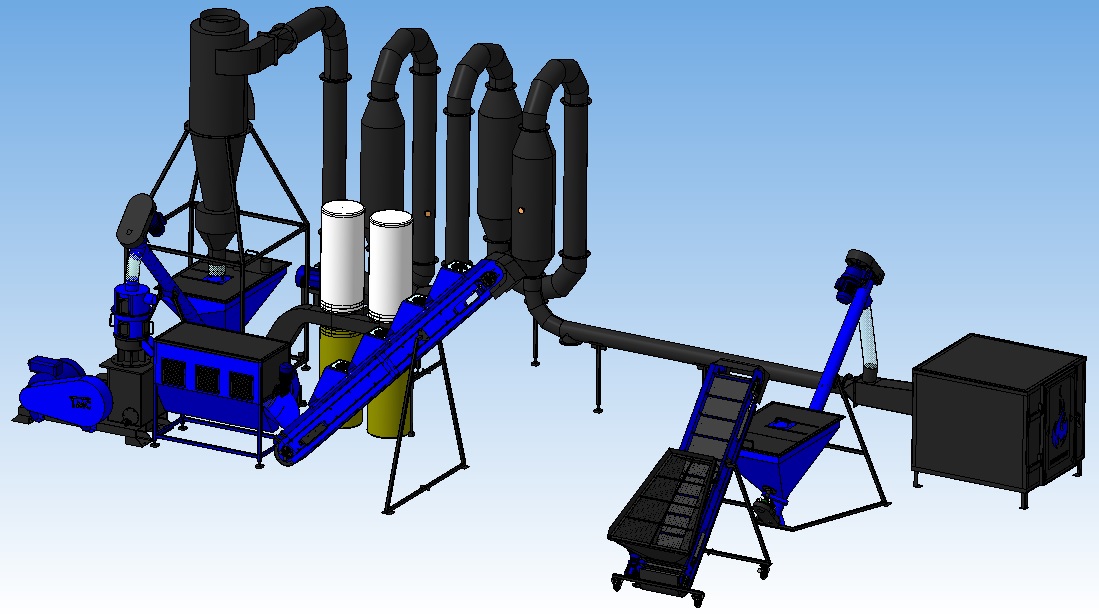

The granulation line can operate as an independent production unit. By adding additional devices, the process of producing pellets and compound feed becomes more automated and efficient.

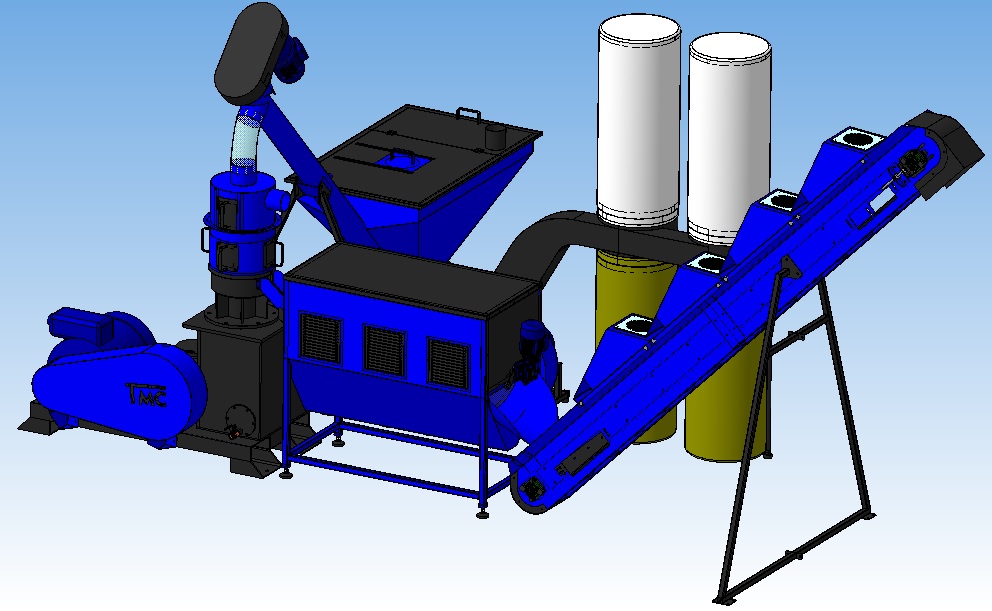

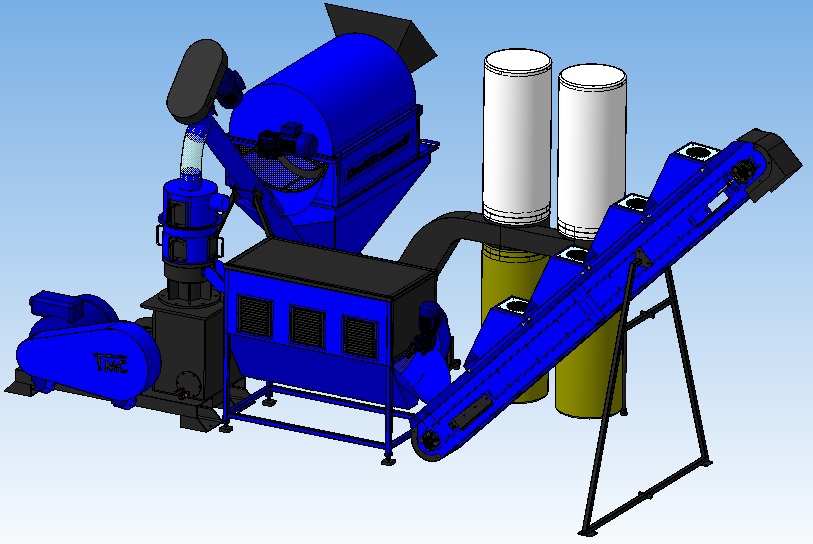

The LDG-3000 KOMBI pellet production line can be supplemented with the following modules:

PK-2 (calibrator-conveyor), whose main task is feeding and calibrating raw materials;

PT-250 (belt conveyor), mainly for feeding and cooling the material;

PT-500 (belt conveyor), mainly for feeding and cooling the material;

RD-500 (shredder), mainly for grinding raw materials (straw, hay, shavings, etc.) to the desired fraction;

KPS-400 (calibrator-feeder), mainly for calibrating the raw material and ensuring even feeding;

KC-200 (extended calibrator-cooler), mainly for cooling and calibrating finished granules;

SA-400 (aerodynamic drying with calibrator), mainly for calibrating and drying raw materials.

Types of lines

1. LDG-3000 KOMBI 25 kW Line

2. LDG-3000 KOMBI Line + Belt Conveyor PT-500 with fans

3. LDG-3000 KOMBI line with calibrator (bunker equipped with a drum screen to filter out bark, wood pieces, branches, debris) + Belt Conveyor PT-500 with fans |

4. LDG-3000 KOMBI Line + Belt Conveyor PT-500 with fans + Shredder RD-500 with cyclone

5. LDG-3000 KOMBI Line + Belt Conveyor PT-500 with fans + Shredder RD-500 with cyclone + belt feeder-calibrator PT-1000

6. LDG-3000 KOMBI Line + Belt Conveyor PT-500 with fans + Aerodynamic Sawdust Dryer SA-400

7. LDG-3000 KOMBI Line + Belt Conveyor PT-500 with fans + Aerodynamic Sawdust Dryer SA-400 + belt feeder-calibrator PT-1000

8. LDG-3000 KOMBI line + Belt Conveyor PT-500 with fans + Shredder RD-500 with cyclone (table free of charge) + belt feeder-calibrator PT-1000 + Aerodynamic Sawdust Dryer SA-400

Additionally, you can order spare parts for the equipment from us, for example, a set of dies with holes of 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, and 8 mm, allowing you to produce pellets of various sizes.

Advantages of the LDG-3000 (KOMBI) granulation line

- High efficiency – enables production of up to 400 kg of pellets or up to 700 kg of feed per hour from various raw materials.

- High power and durability of the pelleting machine – moving rollers ensure high power and reliability during pellet granulation.

- Versatile use – suitable for granulating many raw materials including sawdust, straw, wood waste, sunflower husks, feed, and even plastics.

- Personalization options – wide range of available configurations and expansion options (e.g. shredders, dryers, conveyors).

- Easy operation and automation – intuitive control panel and the option to equip with automation for feeding and cooling systems.

- Compact dimensions – suitable for working in limited spaces, reducing costs associated with renting or purchasing a hall.

- Cost reduction and eco-friendliness – helps efficiently utilize and dispose of waste and reduces production costs by owning your own pellet or feed production.

- Safety and reliable operation – high quality workmanship, thermal protection system, and ammeters for each motor section of the line.

Applications of the LDG-3000 (KOMBI) pellet production line

The LDG-3000 KOMBI line is used in the woodworking, sawmill, agricultural industries as well as in the production of fuel pellets and animal compound feeds.

The model is designed for the production of:

- pellets from sawdust, shavings, wood chips,

- pellets from biomass,

- fuel pellets from organic waste,

- plastic granules, which are used e.g. in pipe production

For customer convenience, we offer comprehensive support: selection of a line tailored to individual requirements, as well as help with installation, commissioning, and process optimization.

Need more information about this device?

Contact us – we will advise you on the best solution for you!

Contact us

Wszystko elegancko śmiga. Śmiało podjedź, chętnie zaprezentuje swój osprzęt.