Vibration table / vibration calibrator SW-1

- Product Code: SW-1

Description

SW-1 Vibrating Table is a specialist industrial calibrator designed for the effective screening and cleaning of bulk materials, especially pellets and non-granulated raw materials.

The device is designed to improve the quality of the final product by eliminating fine dust contaminants and fractions that do not meet technological requirements.

SW-1 can work with different types of screens, selected according to the customer's request. This ensures flexibility in adapting the device to specific producer needs. The calibrator is equipped with special outlets for receiving finer fractions – with the possibility of connecting to an extraction system or using a collection container.

It is possible to test this machine on your material at our warehouse!

Key advantages of the SW-1 vibrating table:

- Compact design – ideal for pelleting or feed lines where workspace is at a premium

- Precise pellet cleaning – effectively removes fine particles, dust, and waste not meeting quality standards

- Possibility to cool the raw material – by properly connecting a dedusting system (e.g., SO), the device can also function as a cooler during screening

- Enclosed design with inspection windows – ensures safe operation and allows process monitoring

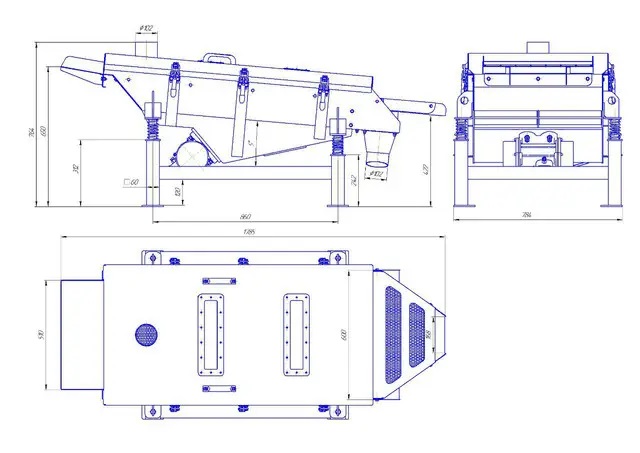

- Stable and damped operation – use of spring supports and special pads eliminates unwanted vibrations Technical drawing:

Applications

SW-1 calibrator is perfect for production plants involved in the production of fuel pellets and feed granulate. SW-1 can be an integral part of a production line, responsible for the final processing of granulate – cleaning and cooling. The device is intended for both companies seeking to improve pellet quality and those needing to optimize the conditions for packing and storage of finished granulate.

Thanks to its functionality and solid construction, SW-1 is an essential tool for any modern pellet and granulate producer.

Mechanism of operation of the vibrating table:

To understand how a vibrating table can improve the quality and commercial appearance of granules, it is worth getting acquainted with the device's construction and principle of operation. The body of the vibrating pellet screener-cooler is completely enclosed. However, the operation of the device can be observed through special inspection windows.

Both the upper and lower parts of the body components are equipped with air connections. This is where dedusting systems are connected. The widest part of the device's housing contains the so-called central line, where the mesh is installed.

The mesh is mounted at the proper angle to the horizontal. In conjunction with the vibrator, this angle ensures the continuous movement of granules from the entry point to the exit point within the screener. The device's body is mounted on a frame using spring vibration isolation elements.

For maximum protection of the device—and above all, the vibrator drive—from accidental mechanical damage, it is placed directly under the housing. Meanwhile, the elimination of excessive motor vibrations is achieved thanks to adjustable pads.

At the bottom there are outlets for fine particles that fall through during operation. They can be removed using the SO aspiration system or collected in special containers.

It is worth noting that if the raw material composition only requires granule screening for cleaning, a simple drum calibrator can be used. However, in situations where, in addition to cleaning, the product also needs to be cooled, the best solution will be a vibrating pellet screener-cooler from the KC series.

Ensuring efficient device operation:

Effective operation of the vibrating table in the cooling mode is ensured by the parallel operation of the device with the cooling system of the SO extraction unit. The more powerful the dedusting system, the higher the degree of pellet cooling that can be achieved.

The highest degree of cooling can be obtained when the upper air connection on the body is not used during operation or is capped. In this case, the extraction system connects only to the lower air connection. This way, the air drawn in by the device flows directly through the screening mesh, providing continuous airflow over the granules during their stay in the screener.

Technical characteristics:

- Weight — 150 kg

- Power — up to 500 W

Need more information about this device?

Contact us — we will advise you on the best solution!

Contact us