Linea per la produzione di bricchette LDB-350 DUO con essiccatore SA-800

- Codice Prodotto: LDB-350Duo+SA-800

Descrizione

Linea per la produzione di biocombustibile LDB-350 DUO con essiccatore SA-800 è una linea di produzione completa per la lavorazione della biomassa con umidità fino al 60% in briquette combustibili Nestro ad alta energia e di qualità. LDB-350 DUO combina le funzioni di essiccazione, separazione, trasporto e compressione delle materie prime.

La capacità della linea raggiunge 700kg/h.

LDB-350 serve a trasformare i residui organici in un combustibile solido prezioso ed ecologico, sotto forma di blocchi compatti.

È possibile testare questa macchina con la tua materia prima presso il nostro magazzino!

Funzionamento della linea tecnologica

Il processo produttivo delle briquette inizia con il versamento della materia prima nel calibratore KPS-600, che separa le impurità.

La materia prima pulita viene inviata al sistema di essiccazione SA-800, dove l'aria riscaldata dal forno in chamotte scalda la biomassa in un sistema aerodinamico.

La fase successiva consiste nell'alimentare la materia prima essiccata a due bricchettatrici BT-350. Il trasportatore PS-200 DUO è responsabile dello spostamento della biomassa.

La polvere generata all’interno dell’impianto durante tutto il processo di produzione viene captata dal sistema di aspirazione SO-2. La polvere raccolta viene reintrodotta per un nuovo utilizzo.

Tutto il processo produttivo delle briquette è gestito da pannelli di controllo.

Nella fase successiva viene pressata la briquette compatta e densa.

Principali vantaggi della linea per la produzione di pellet LDB-350 DUO con essiccatore SA-800

- Possibilità di lavorare biomassa con umidità fino al 60%

- Alta produttività: 500–700 kg/h

- Essiccatore efficiente con forno in chamotte

- Doppio sistema di bricchettatrici e tramogge

- Bussole formanti intercambiabili che consentono la regolazione del diametro e della lunghezza delle briquette

- Tipo di briquette: Nestro (rotonda, senza foro)

- Diametro standard: 50 mm (altri su richiesta)

- Lunghezza delle briquette: regolabile (200–300 mm)

- Alimentazione: 380–400 V, 50–60 Hz

- Potenza complessiva: 66 kW

- Il sistema di aspirazione riduce l’emissione di polveri e aumenta l’efficienza

- Gestione da pannello operatore con funzione di monitoraggio e protezione

- Garanzia: 12 mesi

Vantaggi delle briquette rispetto alla biomassa grezza

- Maggiore potere calorifico (10–20% in più di energia)

- Minore consumo di combustibile a parità di energia

- Minori emissioni di fumo e polveri

- Quantità di cenere ridotta (2–3 volte in meno)

- Migliore logistica: trasporto e stoccaggio più facili

- Qualità e forma stabile del combustibile

- Materia prima rinnovabile, conforme ai principi dello sviluppo sostenibile

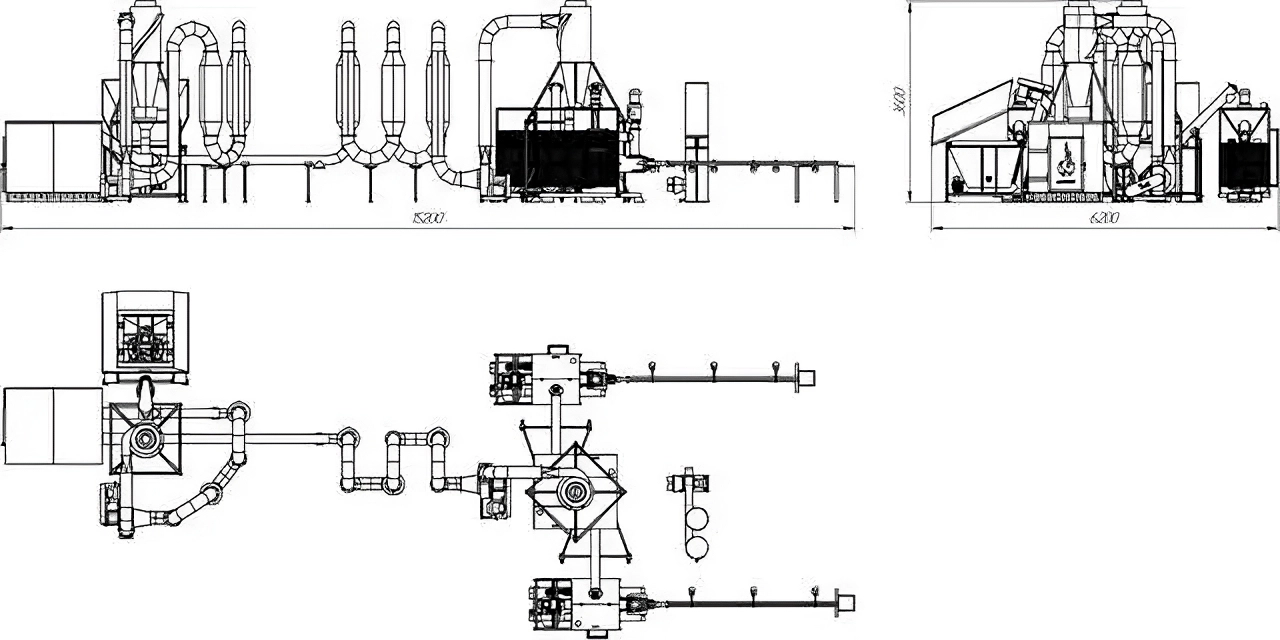

Disegno tecnico:

Applicazione

La linea per la produzione di briquette LDB-350 DUO con sistema di essiccazione SA-800 è una soluzione eccellente per tutti i tipi di aziende di trasformazione, industrie e aziende agricole con grandi quantità di biomassa.

La linea di produzione di briquette consente di trasformare i rifiuti destinati allo smaltimento in combustibile solido ecologico e ad alta energia.

La produzione propria di briquette è una soluzione vantaggiosa sia economicamente che ecologicamente.

La linea comprende:

- Essiccatore aerodinamico SA-800 – 14,7 kW

- Pressa per briquette BT-350 – 2 pz. da 23 kW

- Tramoggia a coclea PS-200 DUO – 3 kW

- Sistema di aspirazione SO-2 – 1,5 kW

- Pannello di controllo linea

Dati tecnici

- Potenza totale motori: 65,2 kW

- Capacità produttiva: 500–700 kg/h

- Diametro briquette: 50 mm

- Tipo di briquette: cilindro rotondo senza fori

- Lunghezza briquette: qualsiasi

- Dimensioni (L×P×A): 18 000 × 5000 × 2300 mm

- Peso: 4000 kg

Hai bisogno di maggiori informazioni su questo dispositivo?

Contattaci – ti consiglieremo la soluzione migliore per te!

Contattaci