Пресс для макулатуры BM-10 OPTI

- Модель: BM-10 OPTI

Описание

Пресс-подборщик для макулатуры BM-10 Opti — это современная и эффективная машина для прессования бумажных отходов, картонных коробок, пластика ПЭТ и лёгких металлических элементов. Пресс BM-10 Opti был создан с учётом потребностей предприятий, магазинов, офисов и учреждений, где важна оптимизация управления отходами и снижение затрат на их вывоз.

Прессование с усилием 10 тонн занимает всего 43 секунды и уменьшает объём отходов до 90%. BM-10 Opti — это относительно компактное устройство, создающее немного шума (до 79 дБ). Благодаря этому его можно установить даже в небольших складских помещениях.

Возможна проверка работы этого оборудования на вашем сырье у нас на складе!

Основные преимущества пресса BM-10 Opti

- Высокое усилие прессования — 10 000 кг — эффективное прессование бумаги, картона, пластика и лёгких металлических отходов

- Быстрый рабочий цикл — 43 секунды — высокая производительность и экономия времени

- Эффективное уменьшение объёма отходов — до 90% — ниже затраты на транспортировку и хранение

- Универсальное применение — бумага, картон, ПЭТ, лёгкие металлические отходы

- Компактные размеры — возможность установки в ограниченном пространстве

- Низкий уровень шума — до 79 дБ — работа в комфортных условиях

- Надёжная конструкция и гидравлическая система — долговечная эксплуатация

Преимущества для пользователя

- Значительное снижение расходов на вывоз отходов (до 70–80%)

- Возможность дополнительного дохода от продажи спрессованных тюков

- Улучшение организации труда и порядка на месте хранения отходов

- Быстрая окупаемость инвестиций — в среднем за 8–12 месяцев

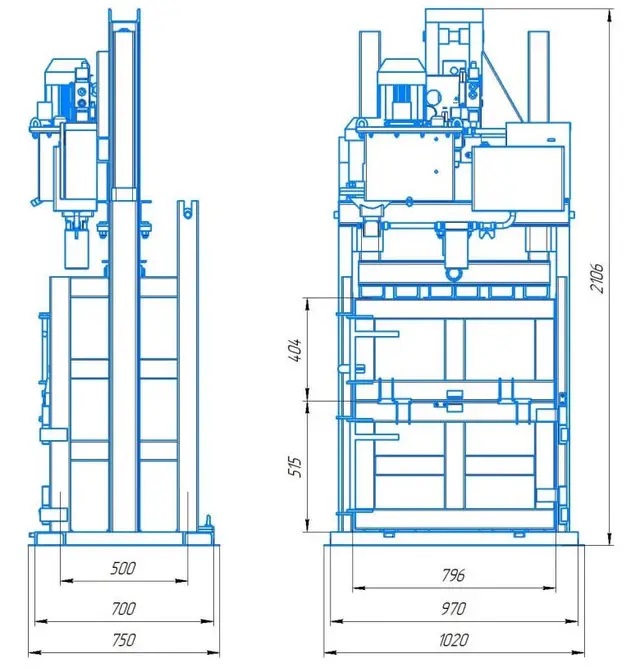

Технический чертёж:

Применение

Пресс для макулатуры BM-10 Opti — отличное решение для предприятий, занимающихся отправкой и продажей. Отлично подходит для складов, крупных магазинов и торговых центров.

Устройство прекрасно справляется с прессованием бумаги, картона, газет, журналов, пластиковых бутылок ПЭТ и лёгких металлических отходов. Эксплуатация BM-10 Opti проста и не требует специального обучения.

Технические данные

Максимальное усилие прессования: 10 000 кг

Время полного цикла: 43 секунды

Скорость рабочего движения: 25 секунд

Скорость обратного движения: 18 секунд

Удельное давление прессования: 2,5 кгс/см²

Давление рабочей жидкости: 170 МПа

Объём бака: 24 л

Ёмкость гидросистемы: 28 л

Вес пресса: 426 кг

Вес тюка: до 160 кг

Размеры тюка (Д×Ш×В): 800 × 500 × 500 мм

Загрузочное окно: 800 × 400 мм

Ход поршня: 630 мм

Мощность: 1,5 кВт

Количество станций для обвязки: 2

Выброс тюка: интегрированная плита

Уровень шума: до 79 дБ

Нужна дополнительная информация об этом оборудовании?

Свяжитесь с нами — мы подберём лучшее решение для вас!

Связаться с нами