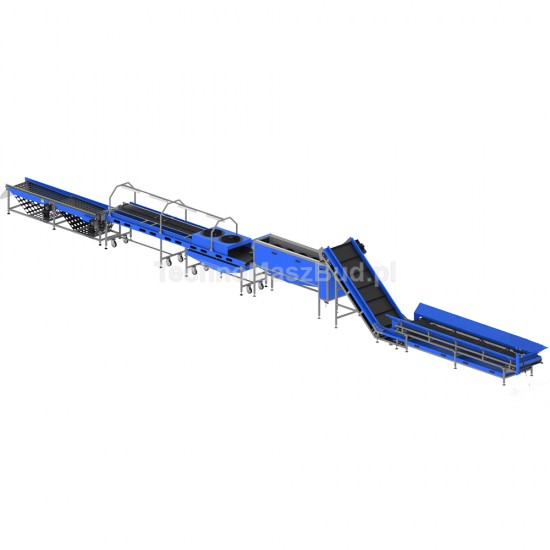

Mycí linka na zeleninu LDW-830 s inspekčním stolem

- Kód výrobku: LDW-830

Popis

Linka LDW-830 vybavená inspekčním stolem je komplexní systém pro automatizaci mytí a inspekce zeleniny. Je navržena především pro potravinářský průmysl, kde hraje klíčovou roli při přípravě zeleniny pro další zpracování nebo balení.

Linka LDW-830 se skládá z 8 modulů, které provádějí řadu klíčových operací, jako jsou:

- nakládání– zelenina je nakládána natyčový dopravník s násypkou o objemu 2,5 m3. K tomu lze využít vyklápěč na boxpalety (volitelné) nebo nakladač (není součástí sestavy);

- přeprava– k této činnosti sloužípásový dopravníkve tvaru „L“, který efektivně a šetrně přepravuje zeleninu a zajišťuje správnou kapacitu i ohleduplné zacházení se zeleninou;

- mytí– proces mytí probíhá v bubnové myčce s výstupním dopravníkem, kde produkt třením o stěny bubnu dochází k čištění. Po umytí jsou produkty dopravovány do další fáze zpracování pomocí dopravníku;

- kartáčování– kořenová zelenina je myta v nádobě s rotujícími kartáči a vodními tryskami. Voda pod vysokým tlakem odstraňuje nečistoty a rotační kartáče zajišťují důkladné čištění. Po umytí je zelenina přepravena na výstupní tác;

- sušení ovoce a zeleniny– proces odvodnění probíhá pomocí stroje s plstěnými válečky, které zajišťují efektivní odstranění vlhkosti z produktů;

- inspekce– zelenina je ručně tříděna na inspekčním stole. Poškozené nebo znečištěné kusy jsou vyřazeny.

Celá linka je ovládána jedním ovládacím panelem, který umožňuje řízení všech jejích prvků. Tento panel umožňuje napájení jednotlivých komponentů, regulaci rychlosti podávacích pásů a inspekčního stolu i rychlosti kartáčů. Je také vybaven ukazatelem napájení, frekvenčními měniči a nouzovým tlačítkem pro zastavení. Navíc je každý prvek linky vybaven vlastním nouzovým tlačítkem.

Příklad umístění linky a rozměry.

Vlastnosti a přednosti linky LDW-830 na mytí zeleniny s inspekčním stolem:

- celkový výkon: až 3000 kg/h;

- celkové rozměry pouze 27 x 0,9 x 1,7 m;

- k připojení stačí elektrická přípojka na 14,2 kW a až 7 m3/h vody pod tlakem ≥ 3 atm;

- způsoby nakládání: vysokozdvižný vozík, kontejnerový vyklápěč, ručně sypané nebo jinak;

- objem násypky: 2,5 m3;

- najednou lze naložit 70–80 % objemu násypky;

- jeden ovládací panel pro všechny prvky linky (samostatné panely pro každý prvek – volitelné);

- snadná instalace – linka je snadná k instalaci a uvedení do provozu, což umožňuje rychlé zahájení práce;

- možnost rozšíření – linku lze rozšířit o další moduly, například optické třídiče a balicí stroje.

Volitelné příslušenství:

- vyklápěč na boxpalety;

- třídění podle hmotnosti (lze nastavit individuálně, běžně používané 40, 50, 55, 60 g);

- balení do pytlů, sítí, vaků v rozsahu balení 5–30 kg;

- prvky linky (kromě kalibrátoru) lze vybavit kolečky o průměru 160 mm pro snadné přesouvání a údržbu.

Díky svým přednostem je linka LDW-830 optimálním řešením pro výrobní závody, potravinářské zpracovny i velkoobchody s ovocem a zeleninou, které hledají efektivní metody mytí a inspekce zeleniny. Linka umožňuje zvýšit produktivitu, zlepšit kvalitu výrobků, zajistit hygienické pracovní podmínky i snížení nákladů na práci a odpad.