Линия для производства брикетов LDB-350 Duo

- Модель: LDB-350Duo

Описание

Комплексная система переработки биомассы в твердые брикеты

Линия по производству брикетов LDB-350 DUO — это полнофункциональная и хорошо оптимизированная технологическая система, предназначенная для непрерывного и эффективного производства топливных брикетов из биомассы. Комплекс машин LDB-350 DUO позволяет изготавливать высокоэнергетическое твердое топливо из таких исходных материалов, как опилки, листья, солома, картон и других сухих отходов

Конечным продуктом линии прессования брикетов из биомассы являются плотные брикеты типа Nestro.

Компактная конструкция, интуитивное управление и эффективные компоненты делают линию LDB-350 DUO идеальным решением для промышленных предприятий, сельских хозяйств и компаний по переработке отходов.

Есть возможность провести тест этого оборудования на вашем сырье на нашем складе!

Основные компоненты

- Два брикета BT-350 — механико-поршневые прессы с производительностью до 350 кг/ч каждый. Позволяют получать брикеты с регулируемой длиной и диаметром (сменные формующие втулки).

- Шнековый дозатор PS-200 DUO — система двух независимо управляемых шнеков с частотными преобразователями для точной подачи сырья в брикетировочные прессы.

- Система аспирации SO-2 — замкнутая фильтрационная система для удаления пыли и загрязнений. Пыль возвращается в производство, что повышает эффективность и минимизирует потери.

- Панель управления — центральная система контроля для управления всеми элементами линии. Оснащена дисплеями параметров, термозащитой и возможностью ручной настройки.

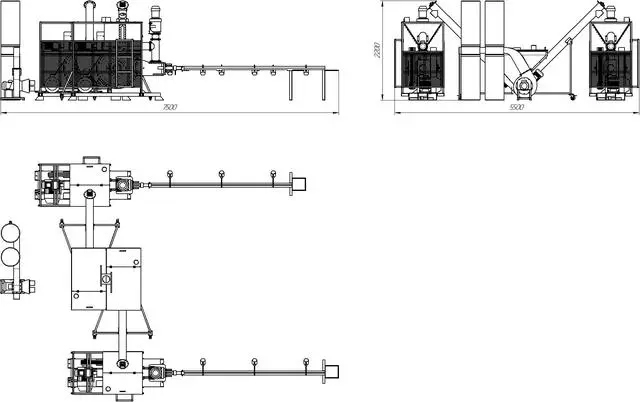

Технический чертеж:

Преимущества использования LDB-350 DUO:

- Высокая производительность — общая производственная мощность до 700 кг/ч

- Модульность — возможность регулировки параметров брикетирования (диаметр, длина, степень уплотнения)

- Безопасность и эргономика — пыль не выходит в окружающую среду, а эксплуатация не требует длительного обучения

- Экология и экономия — использование биомассы и отсутствие необходимости связующих компонентов

- Разнообразие применения — подходит как для отопления, так и для кормового назначения или переработки отходов

Применение

LDB-350 DUO — это решение для компаний, которым необходим эффективный комплекс по переработке сухих отходов в возобновляемое топливо. Получаемые в процессе брикеты идеально подходят для сжигания в печах, каминах, котлах и промышленных установках.

Линия для производства брикетов LDB-350 DUO подходит для деревообрабатывающих предприятий, лесопилок, хозяйств и компаний по переработке отходов. LDB-350 DUO — это решение, объединяющее производительность, рентабельность и экологичность.

Технические характеристики

- Суммарная мощность электродвигателей: 50,5 кВт

- Производительность: 500–700 кг/ч

- Диаметр брикета: 50 мм

- Тип брикета: круглый цилиндр без отверстий

- Длина брикета: любая

- Размеры (Д×Ш×В): 5700 × 5000 × 2300 мм

- Масса: 3200 кг

Нужна дополнительная информация об этом оборудовании?

Свяжитесь с нами — мы подберём для вас оптимальное решение!

Связаться с нами