Аэродинамическая сушилка SA-800 PRO (двухконтурная)

- Модель: SA-800-PRO

Описание

Двухконтурная аэродинамическая сушилка для опилок SA-800 PRO — это современная машина для удаления влаги из сырья мелкой фракции, такого как, например: опилки, стружка, солома и зерновые отходы.

Различие между моделями SA-600 и SA-800 заключается в том, что модель SA-800 оснащена вторым контуром трубопроводов с дополнительным циклоном и вентилятором, что позволяет более эффективно сушить сырье и, тем самым, увеличивает производительность сушилки.

Модель SA-800 PRO — это расширенная версия SA-800, дополнительно оснащённая автоматической пеллетной горелкой. Чаще всего используется для подготовки материала к пеллетированию, гранулированию или брикетированию.

SA-800 PRO — это аэродинамический трубопровод, в котором циркулирует поток горячего воздуха. Источником тепла служит подключённая пеллетная горелка DOMNA-350. Автоматические пеллетные горелки (DOMNA-250 и DOMNA-350) также совместимы с аэродинамическими сушилками SA-400 и SA-600 нашего производства. Для установки такой горелки достаточно заменить дверь на печи.

Есть возможность тестирования этой машины на вашем сырье на нашем складе!

Аэродинамическая сушилка основана на простом принципе: материал сушится в трубопроводе, по которому проходит поток нагретого воздуха. Благодаря воздействию высокой температуры влага с наружного слоя сырья испаряется, а внутренняя влага перемещается к поверхности — такой метод работы снижает риск воспламенения материала. За выработку тепла отвечает подключённая печь с пеллетной горелкой, например например, DOMNA-350.

Машина является идеальным дополнением к линии грануляции LDG-3000 DUO и LDG-4000 DUO.

Сушилка для опилок предназначена для сушки таких материалов, как:

- опилки лиственных и хвойных пород древесины

- стружка

- солома

- зерновые отходы

Этапы работы сушилки для опилок:

- В загрузочный бункер засыпается сырьё объёмом 1 м³, которое просеивается на вибросетке над бункером

- Одновременно в трубопровод подаётся горячий воздух, который часто называют «сушащим агентом».

- Вместе с сушащим агентом сырьё транспортируется по трубопроводу.

- Под воздействием высокой температуры влага с поверхности сырья испаряется, а внутренняя влага перемещается к поверхности.

- Этот процесс и правильно подобранная температура предотвращают возгорание частиц.

На выходе влажность опилок будет оптимальной для производства пеллет. Топливные пеллеты могут производиться для сельскохозяйственных хозяйств, предприятий с собственной котельной, жилых домов, бань и саун и т.д.

Видео: Двухконтурная аэродинамическая сушилка для опилок SA-800:

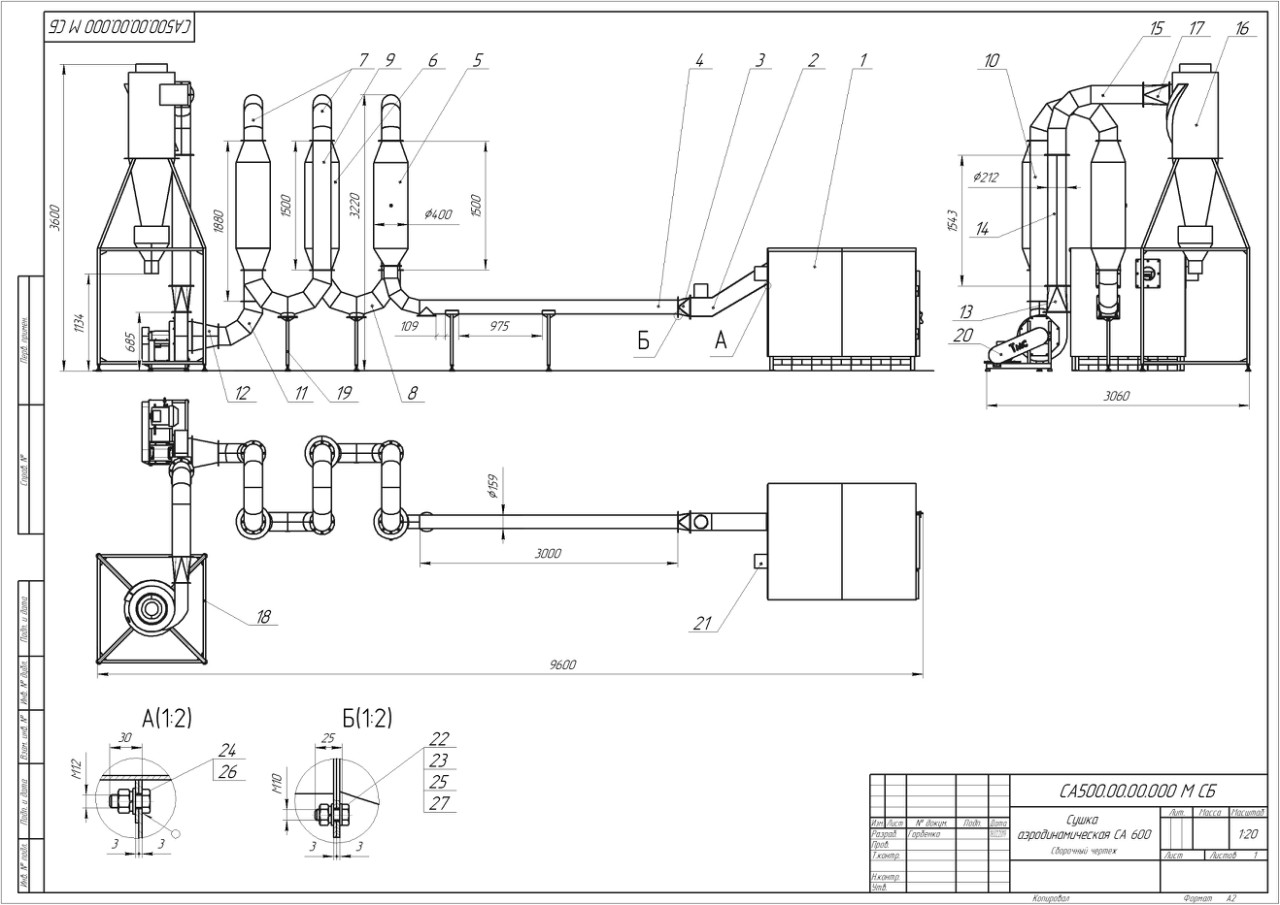

В комплект аэродинамической сушилки SA-800 Pro входят:

- Шамотная кирпичная печь, собранная из 700 шамотных кирпичей

- Пеллетная горелка DOMNA-350 с шнеком и панелью управления

- Калибратор-Шнековый Подающий КPS-600, основная задача которого – калибровка и просеивание сырья (удаление коры, кусков дерева, веток, мусора) и равномерная подача сырья в трубопроводы сушилки

- Система трубопроводов: в этом элементе сушилки происходит сушка сырья во время его прохождения по трубам

- 2 противопылевых радиальных вентилятора: протягивают горячий воздух вместе с сырьём по трубопроводам

- 2 циклона. Используются для очистки газов от твёрдых частиц

- Панель управления. Электрораспределительный шкаф устройств включает в себя оборудование для дистанционного автоматического управления механизмами и электроприводами комплекта, установленными в шкафу управления

- В ПОДАРОК:лазерный цифровой термометр и пресс-маслёнка для смазки

Элементы поставляются отдельно, для сборки на месте.

Товар поставляется в разобранном состоянии (это облегчает транспортировку и позволяет оптимально использовать пространство), и его необходимо собрать самостоятельно.

Монтаж сушилки является ключевым процессом. Рекомендуем проконсультироваться с нашим специалистом по обслуживанию клиентов. Профессиональная техническая поддержка поможет решить любые вопросы и обеспечит правильную сборку сушилки, что повлияет на её эффективность и долговечность.

Кирпич для печи не входит в комплект!

Видео: Линия по производству пеллет LDG-3000 DUO + Сушилка SA-800 | Производство пеллет на лесопилке:

Преимущества сушилки для опилок SA-800 PRO

- Универсальность – позволяет сушить различные растительные материалы, в том числе опилки (хвойных и лиственных пород), стружку, солому и зерновые остатки.

- Высокая производительность – возможность сушки до 800 кг/ч, что соответствует требованиям промышленных предприятий.

- Эффективная сушка – быстрое и точное удаление влаги из легких и измельчённых материалов(от 60% до 6-12%), благодаря чему значительно сокращается время подготовки материала к последующим этапам обработки.

- Современная двухконтурная система – конструкция уменьшает риск возгорания материала путём контроля температуры и оптимальной циркуляции воздуха.

- Лёгкость эксплуатации – после первоначальной настройки процесс работы во многом автоматизирован; контрольная панель и системы безопасности позволяют точно контролировать процесс сушки.

- Энергоэкономичность – устройство характеризуется низким энергопотреблением благодаря использованию печи, что снижает эксплуатационные затраты.

В подарок: лазерный цифровой термометр и пресс-маслёнка для смазки

156,2 kB

Применение трубчатой сушилки для опилок SA-800 PRO

Аэродинамическая сушилка для опилок SA-800 PRO будет полезна везде, где требуется быстрая и эффективная переработка растительных остатков.

Машину можно использовать в деревообрабатывающей и энергетической промышленности, а также в сельском хозяйстве и на предприятиях по производству пеллет.

Нужна дополнительная информация об этом оборудовании?

Свяжитесь с нами — мы подберём для вас наилучшее решение!

Связаться с нами