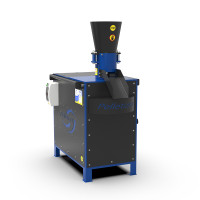

Granulator for feed KGM-100

Available Options

- Product Code: KGM-100

Description

Feed pelletizer KGM-100 from TechnoMaszBud is designed to produce pelleted feed for chickens, broilers, pigs, rabbits, quail, cows, horses, fish, and other farm animals.

Cylindrical pellets are formed by mechanically compressing loose feeds, bran, oil cake, and other grain-processing by-products. Thanks to the high density of the pellets, animals and birds can eat more feed at once, which increases feeding efficiency.

The pellets have the same shape and composition, which allows animals to always, without exception, eat balanced meals, regardless of their health, age, or agility. Animals have no possibility to choose between feed components. Pelleted feeds are characterized by low moisture content, which extends their storage life. Owning a pelletizer can significantly reduce feed production costs—producing your own feed is cheaper than buying ready-made feed.

In addition, you can prepare a mix according to an individual formula tailored to your needs. The KGM-100 pelletizer is equipped with a die with holes from 2 to 6 mm in diameter, allowing pellets of various sizes.

You can test this machine with your raw material at our warehouse!

Advantages of feed pelleting

• Lower unit costs of feed production

• Longer feed shelf life

• High feed density—more nutrients in the animal’s limited-volume stomach

• Eliminates situations where stronger animals pick out all the tasty components, leaving the rest of the group with incomplete feed

• Removal of up to 95% of mold colonies that produce toxins

• Conversion of starch into dextrins, allowing more efficient use of nutrients

• Even distribution of fat on the feed surface, improving digestion

• All pellets have the same shape and composition, ensuring uniform feeding

• Pelletizer equipped with a single-sided die made of high-alloy hardened steel with holes from 2 to 6 mm to choose from

What’s included

• Pelletizer — 1 pc.

• User manual — 1 pc.

• Die puller — 1 pc.

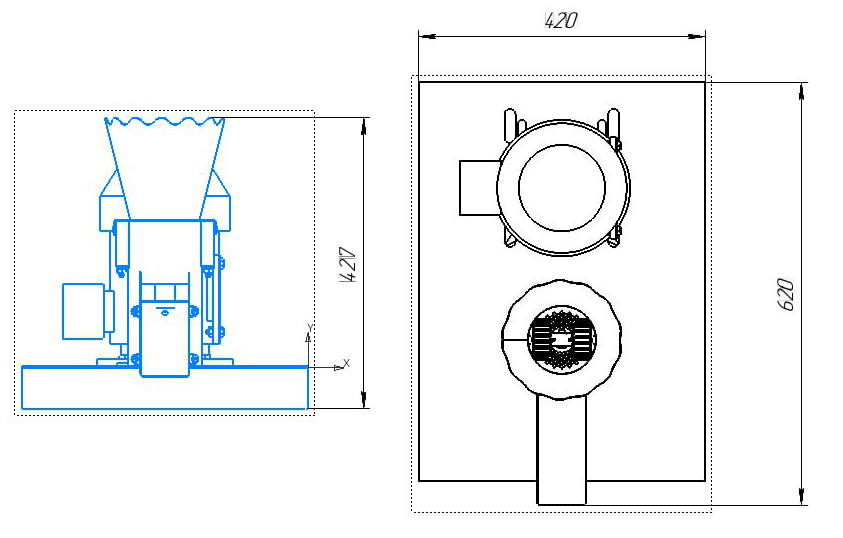

Technical drawing:

Applications

The KGM-100 pelletizer is ideal for producing pelleted feed for various species of farm animals, such as poultry, pigs, rabbits, cattle, and fish. It performs well both in small farms and in professional breeding operations or feed producers. Thanks to the ability to adjust pellet size, the device can be easily adapted to the individual needs of the farmer.

A 1500 rpm motor drives the die via pulleys and a shaft. Rollers pressed against the die force the feed into the die holes.

Technical specifications:

- motor power is 1.5 kW (380–400 V) and 2.2 kW (220–240 V);

- 1500 revolutions per minute;

- using a set of dies, pellets with a diameter of 2–6 mm can be produced;

- output is 40 kg of pellets per hour.

- Roller diameter (1 roller) – 60 mm.

- Roller width (1 roller) – 22.5 mm.

- Die diameter – 100 mm.

Need more information about this device?

Contact us — we’ll recommend the best solution for you!

Contact us