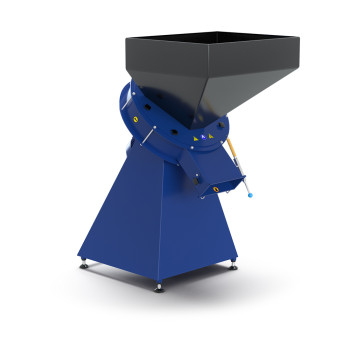

Kod produktu: LIDER-4

5 850.00zł

Dostępność: W magazynie

Śrutownik grawitacyjny LIDER-4 to wydajne i niezawodne urządzenie do rozdrabniania zbóż i innych sur..

Kod produktu: KRAFT

5 960.00zł

Dostępność: W magazynie

Młyn bijakowy / śrutownik KRAFT to wydajne urządzenie do rozdrabniania i mielenia różnych surowców, ..

Kod produktu: MB-500

35 400.00zł

Dostępność: W magazynie

Młyn bijakowy MB-500 to urządzenie przeznaczone do rozdrabniania zboża, wiórów, trocin, łupin i zręb..

Kod produktu: MB - 500 DUO

87 580.00zł

Dostępność: W magazynie

Młyn bijakowy MB-500 DUO to zestaw łączący dwa klasyczne i sprawdzone w pracy młyny bijakowe MB-500 ..

Kod produktu: MB-1000

79 690.00zł

Dostępność: W magazynie

Młyn bijakowy MB-1000 to wszechstronne i wydajne urządzenie przeznaczone do rozdrabniania różnorodny..

Kod produktu: MB-1200

82 500.00zł

Dostępność: W magazynie

Młyn bijakowy MB-1200 to nasza najpotężniejsza maszyna przeznaczona do rozdrabniania różnorodnych su..

Kod produktu: ZB-1 + Kraft-4 kW + Cyklon

10 650.00zł

Dostępność: W magazynie

Zbiornik ZB-1 w połączeniu z rozdrabniaczem ziarna Kraft-4 kW oraz cyklonem tworzy kompaktowy, wydaj..

Kod produktu: Zbiornik ZB-1 + Kraft-4 kW + Mieszalnik MP-1000

19 450.00zł

Dostępność: W magazynie

Zbiornik ZB-1 do materiałów sypkich to solidne i niezawodne urządzenie przeznaczone do stabilnego po..

Kod produktu: ZB-1

1 090.00zł

Dostępność: W magazynie

Zbiornik ZB-1 to funkcjonalne i kompaktowe urządzenie przeznaczone do pracy z rozdrabniaczami serii ..

Kod produktu: ZB-2

3 270.00zł

Dostępność: W magazynie

Zasobnik ZB-2 - to solidny i funkcjonalny podajnik przeznaczony do ciągłego oraz bezawaryjnego trans..

Kod produktu: TYTAN-5 + MB-1000

119 300.00zł

Dostępność: W magazynie

Młyn bijakowy MB-1000 to profesjonalna i niezawodna maszyna do rozdrabniania wiórów, zrębków, odpadó..

Kod produktu: TYTAN-5

36 800.00zł

Dostępność: W magazynie

Zbiornik-podajnik TYTAN-5 łączy funkcje przechowywania i podawania surowców - to wydajne i w pełni a..

Wysokiej jakości młyn bijakowy od TechnoMaszBud

Jeśli prowadzisz własne gospodarstwo lub produkcję pasz bądź paliwa opałowego, w naszej ofercie znajdziesz profesjonalne maszyny przemysłowe, które usprawnią Twoją pracę.W prezentowanym dziale dostępna jest wysokiej jakości maszyna do mielenia trocin. To urządzenie oferujemy w różnych wariantach. Do Twojej dyspozycji oddajemy następujące modele: MB-500, MB-500 DUO. Mamy także zbiorniki ZB-1, które służą do dostarczania materiału do rozdrabniaczy serii KRAFT. Śrutownik z naszej oferty to sprzęt, który jest efektem wielu godzin pracy specjalistów, inżynierów i fizyków. Wszystko po to, by zautomatyzować pracę w Twojej firmie.

Maszyna do mielenia trocin, zboża, zrębki — postaw na niezawodne rozwiązania!

Prezentowana w ofercie maszyna do mielenia zboża, trocin lub zrębki to urządzenie działające na zasadzie zasysania surowca przygotowanego do mielenia czy suszenia. Sprzęt może być obsługiwany przez jedną osobę. Został zaprojektowany z wykorzystaniem odpowiedniej jakości elementów, które przekładają się na efektywność i wytrzymałość. To dla nas priorytetowe kwestie, szczególnie z uwagi na fakt, że doskonale znamy specyfikę pracy produkcyjnej. Młyn bijakowy często musi pracować na najwyższych obrotach i to przez wiele godzin. Dlatego musi posiadać odpowiednie mechanizmy centralnego smarowania czy funkcje, odpowiadające za jego wydajność. Nasze urządzenia są objęte wielomiesięczną gwarancją, a co najważniejsze powstają z uwzględnieniem wszelkich obowiązujących norm. Wybierając młyn ssąco-tłoczący, możesz mieć pewność, że stawiasz na wysokiej jakości mechanizm.Młyn ssąco-tłoczący — dlaczego warto wybrać go u nas?

Warto wybrać właśnie nasz młyn bijakowy z uwagi na wysoką jakość wykonania, kompaktowy rozmiar sprzętu, a także wygląd. Urządzenie może obsługiwać tylko jeden pracownik. Co ważne, zmieści się w niewielkiej hali produkcyjnej. Śrutownik zapewnia równomiernie rozdrobnienie surowca. Jest wyposażony w kompaktowy podajnik, który ułatwia pracę. Mała waga pozwala na łatwe przemieszczanie sprzętu i jego przechowywanie.U nas znajdziesz urządzenia o różnorodnej efektywności. Dopasujesz je zatem do niewielkich przedsiębiorstw, jak i dużych zakładów produkcyjnych, chcących przetwarzać nawet 2000 kg surowca w ciągu godziny.

Jak wybrać odpowiedni śrutownik?

Młyn ssąco-tłoczący warto dobrać po dokładnym zapoznaniu się z opisami, parametrami,a nawet po obejrzeniu sprzętu w naszej siedzibie, do czego zachęcamy. Wszystkie maszyny są dokładnie opisane, co sprawia, że możesz dowolnie porównywać poszczególne modele. Staramy się także udostępniać zdjęcia oraz filmiki z pracy urządzenia. Jeśli jednak nie jesteś przekonany co do wyboru odpowiedniego modelu, zapraszamy do kontaktu z naszymi specjalistami, którzy pomogą Ci dopasować model adekwatny do Twoich oczekiwań.