Młyn bijakowy MB-1000 + Zbiornik – Podajnik TYTAN-5

- Kod produktu: TYTAN-5 + MB-1000

Opis

Młyn bijakowy MB-1000 to profesjonalna i niezawodna maszyna do rozdrabniania wiórów, zrębków, odpadów z obróbki drewna oraz innych surowców na drobną frakcję przeznaczoną do dalszego procesu produkcyjnego.

Młyn bijakowy do zrębki MB-1000 w zestawie ze zbiornikiem / podajnikiem TYTAN-5 tworzą wydajny i niezawodny system przeznaczony do podawania i mielenie biomasy i surowców sypkich.

Solidna konstrukcja urządzeń, wysoka moc silników oraz możliwość regulacji stopnia rozdrobnienia biomasy sprawiają, że zestaw: młyn bijakowy do drewna MB-100 + zbiornik - podajnik TYTAN-5 to uniwersalne rozwiązanie technologiczne zarówno dla gospodarstw, jak i przedsiębiorstw zajmujących się produkcją pasz, pelletu czy opału.

Istnieje możliwość testu tej maszyny na Twoim surowcu u nas w magazynie!

Wydajność zestawu urządzeń MB-1000 + TYTAN-5

- Rozdrabnianie surowców drzewnych i paszowych – do 1000 kg/h*

- Pojemność podajnika TYTAN-5 – 5 m³

*Wydajność zależy od rodzaju, frakcji i właściwości fizycznych surowca.

Zalety zestawu MB-1000 + TYTAN-5

- Wysoka wydajność przy niskim zużyciu energii;

- Uniwersalność – przetwarza ziarno, trociny, wióry, fornir, zrębki i inne surowce;

- Regulacja frakcji – możliwość ustawienia stopnia rozdrobnienia materiału;

- Prosta i zwarta konstrukcja – ułatwia obsługę i serwis;

- Trwałość i niezawodność – solidna budowa i hartowane podzespoły;

- Niskie koszty eksploatacji – szybka wymiana sit i młotków;

- Bezpieczeństwo użytkowania – zestaw wyposażony w panel sterowania z przetwornicą częstotliwości.

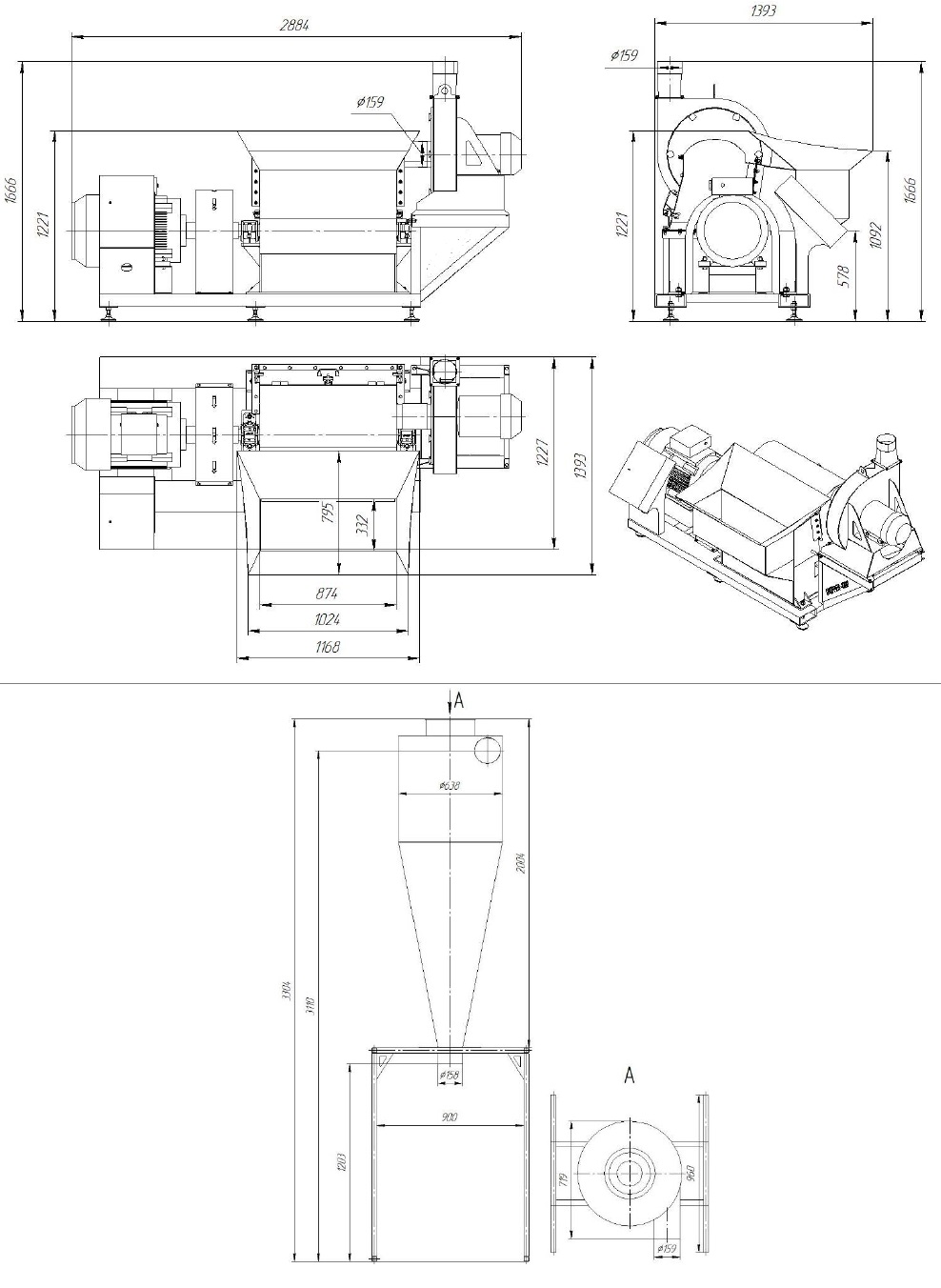

Rysunek techniczny:

Zastosowanie młyna bijakowego MB-1000 + podajnika/zbiornika TYTAN-5

Zestaw urządzeń: Młyn bijakowy do zrębek i drewna MB-1000 + podajnik/zbiornik TYTAN-5 znajduje zastosowanie w gospodarstwach rolnych, zakładach paszowych oraz przedsiębiorstwach zajmujących się obróbką drewna czy tłoczeniem biopaliw, takich jak pellet czy brykiet, z biomasy drzewnej. Zestaw MB-100 z podajnikiem TYTAN-5 umożliwia efektywne i sprawne rozdrabnianie wiórów drewnianych, zrębek, trocin, forniru czy odpadów zbożówych na drobną frakcję o wielkości ustalonej przez osobę obsługującą młyn bijakowy do rozdrabniania MB-1000.

Dzięki podajnikowi TYTAN-5 proces podawania surowca do młyna odbywa się w sposób płynny i zautomatyzowany, co znacznie zwiększa wydajność pracy. Rozdrobniony materiał może być następnie kierowany do cyklonu, mieszalników paszowych lub linii do granulacji.

Zestaw sprawdza się wszędzie tam, gdzie kluczowe znaczenie ma ciągłość podawania surowca, wysoka wydajność i obniżenie kosztów produkcji pelletu, paszy czy innych form granulowanej biomasy.

Film: Zbiornik-Podajnik TYTAN-5 do podawania biomasy

Film: Młyn Bijakowy MB-1000 | Do mielenia odpadów stolarskich, zrębki, ziarna

Wydajność:

- do 1000 kg/h

* Wydajność kruszarki zależy od rodzaju i właściwości fizycznych rozdrabnianego surowca oraz uzyskanej frakcji.

Charakterystyka techniczna:

- Silniki: 55 kW i 11 kW

- Wymiary (D×S×W): 2824 × 1393 × 1666 mm

- Waga: 1980 kg

- Wymiary otworu załadowczego: 870 × 332 mm

- Wysokość załadunku: 1100 mm

- Ilość młotków: 56 szt.

Charakterystyka cyklonu:

- Waga: 70 kg

- Wymiary (D×S×W): 1058 × 1367 × 3302 mm

Zużycie energii elektrycznej:

- 66 kW

Parametry zbiornika TYTAN-5:

- Motoreduktor: 5,5 kW (380-400 V)

- Wymiary (D×S×W): 4600 × 1500 × 1800 mm

- Napęd: łańcuchowy

- Pojemność: 5 m³

- Waga: 840 kg

- W zestawie: panel sterowania z przetwornicą częstotliwości

Potrzebujesz więcej informacji o tym urządzeniu?

Skontaktuj się z nami – doradzimy najlepsze rozwiązanie dla Ciebie!

Kontakt z nami