Linia do granulacji LDG-3000 (KOMBI) PRO

Dostępne opcje

- Kod produktu: LDG-3000-KOMBI-PRO

Opis

Po wielu intensywnych testach, wdrożeniach i udoskonaleniach z dumą prezentujemy linię produkcyjną LDG-3000 KOMBI PRO – nowoczesne rozwiązanie do wytwarzania pelletu o wydajności do 500 kg/h, w zależności od rodzaju surowca.

Dzięki zastosowaniu mocniejszego granulatora PRIME-300 PRO w porównaniu do linii LDG-3000 KOMBI, linia LDG-3000 KOMBI PRO osiąga jeszcze większą stabilność pracy i wyższą wydajność, zachowując prostą obsługę i uniwersalność w przetwarzaniu różnorodnych surowców.

Linia do granulacji LDG-3000 (KOMBI) PRO to nowoczesna i wszechstronna linia technologiczna przeznaczona do produkcji pelletu opałowego, granulowanych pasz dla zwierząt oraz granulatów z tworzyw sztucznych.

ISTNIEJE MOŻLIWOŚĆ TESTU TEJ MASZYNY NA TWOIM SUROWCU U NAS W MAGAZYNIE!

Urządzenie zaprojektowano z myślą o gospodarstwach rolnych, zakładach paszowych, tartakach oraz firmach stolarskich, które poszukują wydajnych i ekonomicznych rozwiązań technologicznych przeznaczonych do przetwarzania biomasy, odpadów rolniczych i drzewnych.

Za wysoką efektywność LDG-3000 (KOMBI) PRO odpowiada współpraca kluczowych komponentów – podajnika ślimakowego, systemu nawilżania, granulatora PRIME-300 PRO, chłodnicy, układu odciągowego oraz panelu sterowania z falownikiem.

Linia charakteryzuje się stabilną pracą, wysoką wydajnością i uniwersalnością zastosowań.

Film: Film: Linia do peletowania trocin sosnowych | Wydajność do 400 kg/h:

Centralnym elementem tej linii jest peleciarka PRIME 300 PRO, kluczowy komponent całego procesu produkcji. Wyposażona w falownik, zapewnia ona nie tylko wysoką wydajność, ale także bezpieczeństwo i precyzyjną pracę silnika. Matryca o średnicy 300 mm może być dostosowana do preferencji klienta, z opcjami otworów o średnicy 6 mm i 8 mm, co pozwala na produkcję pelletu o różnych twardościach.

Dla twojej wygody możemy nie tylko wybrać linię do twoich wymagań, ale także pomóc w instalacji, uruchomieniu i osiągnięciu pożądanego rezultatu!

Budowa i komponenty:

- Podajnik ślimakowy PS-200 PRO – wyposażony w falownik dla płynnej regulacji prędkości podawania oraz magnesy neodymowe eliminujące metalowe zanieczyszczenia.

- System nawilżania (0,37 kW) – zbiornik 100 l, zawór, pompa i dysza zapewniają precyzyjne dozowanie wilgoci w trakcie granulacji.

- Peleciarka PRIME-300 PRO (30 kW) – granulator o wydajności do 500 kg/h (pellet) oraz do 700 kg/h (pasza), z matrycą Ø 300 mm i ruchomymi rolkami; gwarantuje wysoką trwałość i niezawodność procesu.

- Kalibrator-chłodnica KC-200 (0,12 kW) – odpowiada za chłodzenie gotowych granulek i usuwanie pyłu oraz okruchów.

- System odciągowy SO-2 (1,5 kW) – zapewnia cyrkulację powietrza i odbiór pyłu do worków zbiorczych, co poprawia czystość i bezpieczeństwo pracy.

- Panel sterowania z falownikiem – kompaktowy, z amperomierzami i zabezpieczeniami termicznymi; umożliwia pełną kontrolę nad procesem i regulację parametrów pracy.

- Falownik 30 kW - zapewnia łagodny rozruch, regulację prędkości obrotowej, ochronę przed przeciążeniem oraz oszczędność energii, zwiększając tym samym bezpieczeństwo, trwałość i efektywność pracy maszyny.

(Przenośnik taśmowy oraz kable do podłączenia linii nie wchodzą w skład zestawu)

Film: Pomiar wydajności na trocinie dębowej | Linia do pelletu LDG-3000 KOMBI:

Wydajność linii do produkcji pelletu LDG-3000 KOMBI PRO:

- odpady drzewne - 500 kg/h; (wydajność zależy od twardości i rodzaju wsadu);

- słoma - do 500 kg/h;

- pasza - do 700 kg/h;

Najważniejsze jest spełnienie wymogu frakcji i poziomu wilgotności przetwarzanych surowców.

Z jakiego surowca można produkować pellet?

- Trociny twardych i iglastych gatunków drzew;

- Odpady po czyszczeniu słonecznika, kukurydzy, ziarna, słomę, gałęzie, łuskę nasion;

- Odpady po produkcji tworzyw sztucznych.

Z jakiego surowca można produkować paszę?

- Ziarno, zboże, śrutę, siano, mieszankę paszową.

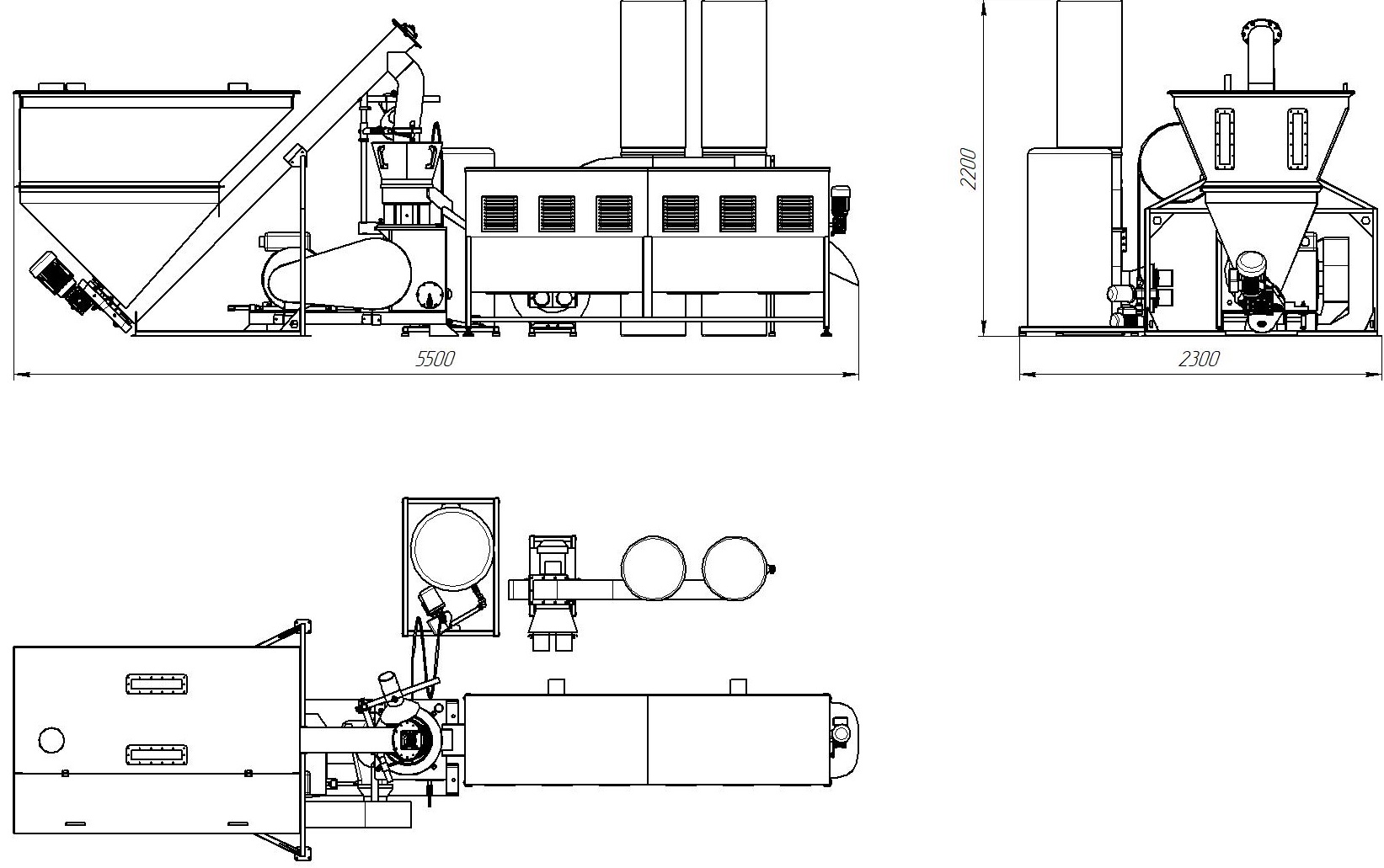

Rysunek techniczny:

Zalety linii LDG-3000 (KOMBI) PRO

- Wysoka wydajność – do 700 kg/h paszy i około 500 kg/h pelletu.

- Nowoczesny granulator PRIME-300 PRO – zwiększona moc i matryca Ø 300 mm umożliwiają pracę z szeroką gamą surowców.

- Kompaktowa i zintegrowana konstrukcja – wszystkie komponenty współpracują w jednej linii, co upraszcza montaż i obsługę.

- Uniwersalność surowców – możliwość przetwarzania trocin, wiórów, słomy, łusek, ziaren, odpadów rolniczych i tworzyw sztucznych.

- Energooszczędność – zoptymalizowany pobór mocy (32 kW) przy wysokiej wydajności.

- Bezpieczeństwo pracy – dzięki systemom odciągowym, falownikowi i zabezpieczeniom termicznym.

- Ekonomiczność i ekologia – minimalizacja odpadów, możliwość ponownego granulowania pyłu i wykorzystania szerokiej bazy surowcowej.

W zestawie znajduje się falownik do silnika peleciarki 30 kW, który ma kilka praktycznych uzasadnień:

- Softstart (łagodny rozruch):

- Silnik podczas uruchamiania pobiera bardzo duży prąd rozruchowy (nawet 6–8 razy większy niż nominalny).

- Falownik ogranicza ten prąd, co chroni instalację elektryczną, bezpieczniki i sam silnik przed przeciążeniem.

- Zmniejsza się ryzyko nagłych uderzeń mechanicznych w przekładnie i sprzęgła.

- Regulacja obrotów:

- Możliwość dopasowania prędkości obrotowej do rodzaju surowca

- Optymalizacja pracy — można znaleźć takie obroty, przy których wytłaczarka ma największą wydajność i najmniejsze zużycie energii.

- Łatwiejsze uruchamianie przy ciężkim rozruchu — najpierw wolne obroty, potem stopniowe zwiększanie.

- Ochrona i kontrola pracy:

- Falownik monitoruje prąd i obciążenie silnika — może zatrzymać maszynę w razie przeciążenia.

- Daje możliwość podłączenia zabezpieczeń, automatyki i sterowania linią.

- Ekonomia i trwałość:

- Mniejsze zużycie energii w porównaniu z pracą na pełnych obrotach przy lekkim obciążeniu.

- Wydłużona żywotność silnika, przekładni i elementów napędowych.

Falownik 30 kW w peleciarce to inwestycja w bezpieczeństwo, elastyczność pracy i niższe koszty eksploatacji.

Wsparcie techniczne i szkolenie

Wraz z dostawą oferujemy kompleksowe wsparcie: montaż, uruchomienie, konfigurację oraz szkolenie personelu (montaż i uruchomienie jest usługą dodatkowo płatną). Dzięki temu użytkownik otrzymuje pewność prawidłowej eksploatacji oraz maksymalnej wydajności w codziennej pracy.

Zastosowanie

Linia do granulacji LDG-3000 KOMBI PRO to kompleksowe rozwiązanie dostosowane do potrzeb przetwórców biomasy.

Urządzenie z powodzeniem sprawdzi się zarówno w przedsiębiorstwach zajmujących się stricte produkcją pelletu opałowego, jak i w gospodarstwach rolnych czy hodowlach zwierząt - jako maszyna do tłoczenia granulowanej paszy.

Potrzebujesz więcej informacji o tym urządzeniu?

Skontaktuj się z nami – doradzimy najlepsze rozwiązanie dla Ciebie!

Kontakt z nami