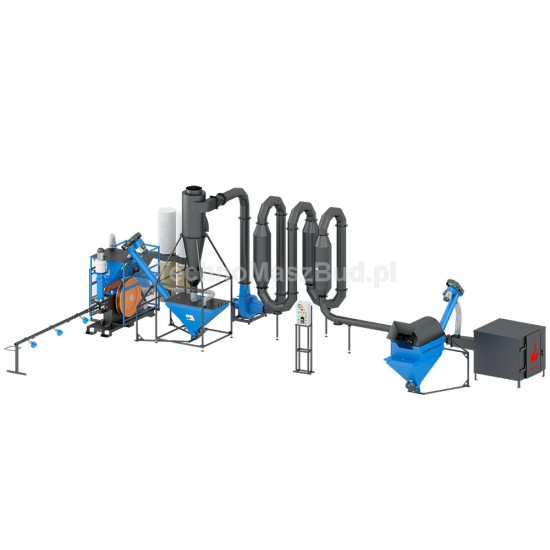

Linia do produkcji brykietu z suszarnią SA-400

- Kod produktu: bt-350+sa-400

Opis

Kompletne rozwiązanie do przetwarzania biomasy w ekologiczne paliwo opałowe

Linia do produkcji brykietu BT-350 z suszarnią SA-400 to kompaktowa i przy tym wydajna i dobrze zoptymalizowana instalacja technologiczna przeznaczona do przetwarzania biomasy w wysokoenergetyczne paliwo stałe.

Linia BT-350 zaprojektowana jest z myślą o brykietowaniu biomasy o wilgotności nawet 60%.

Wartość energetyczna produktu końcowego linii Bt-350 to 3800-6000 kcal/kg. Zastosowanie technologii suszenia aerodynamicznego i tłoczenia mechaniczno-tłokowego pozwala osiągnąć brykieciarce BT-350 wydajność do 350 kg/h przy stosunkowo niskim poborze mocy - około 30 kW.

Istnieje możliwość testu tej maszyny na Twoim surowcu u nas w magazynie!

Kluczowe zalety linii brykietującej z suszarnią SA-400

- Wysoka wydajność suszenia i brykietowania – do 350 kg/h

- Brykiety o stałej jakości – spalają się równomiernie przez 1,5–2 godziny

- Energooszczędność – zoptymalizowane zużycie energii i brak grzejników w procesie

- Ekologiczne paliwo – wysoka wartość opałowa, niska emisja siarki i popiołu

- Zwarta konstrukcja – dopasowana do zakładów z ograniczoną przestrzenią

- Łatwa obsługa – prosta kontrola procesu i szybkie przeszkolenie personelu

- Przetwarzanie różnych surowców – trociny, łuski słonecznika, słoma, trzcina, zboża

- Zgodność z zasadami zrównoważonego rozwoju

Skład zestawu technologicznego

- Brykieciarka BT-350 – wydajność do 350 kg/h, gęstość brykietu do 1,4 kg/cm²

- Suszarnia aerodynamiczna SA-400 – usuwa wilgoć do poziomu 12%

- Podajnik ślimakowy PS-200 – zapewnia stały przepływ materiału

- Układ sterujący i zbiornik roboczy – w pełni zintegrowane w linii

Technologia brykietowania bez spoiw - mniej chemii, więcej energii

Nasza technologia brykietowania została opracowana specjalnie do recyklingu odpadów powstających w obróbce drewna, przetwarzaniu zbóż czy lnu.

Proces prasowania pod wysokim ciśnieniem bez środków wiążących zastosowany w linii do brykietowania biomasy BT-350 wykorzystuje naturalną ligninę zawartą w surowcach, która pod wpływem temperatury i ciśnienia działa jak spoiwo naturalne.

Film: Brykietowanie trocin/słomy | Brykieciarka mechaniczno-tłokowa BT-350

Dlaczego brykieciarka mechaniczno-tłokowa to strzał w dziesiątkę?

Produkcja brykietów z biomasy eliminuje konieczność składowania odpadów, przekształcając je w paliwo o wartości opałowej zbliżonej do węgla, ale z kilkadziesiąt razy niższą zawartością popiołu!

Zastosowanie linii do produkcji brykietu z suszarnią SA-400

Linia produkcyjna do paliwa stałego BT-350 z suszarnią Sa-400 to rozwiązania stworzone z myślą o zakładach przetwórstwa drewna, zakładach tartacznych, gospodarstwach rolnych ze stałym dostępem do biomasy, firmach zajmujących się przetwórstwem biomasy, zakładach przetwórstwa rolno-spożywczego i przedsiębiorstwach energetycznych.

Kompaktowa konstrukcja i niewielkie koszty eksploatacji linii BT-350 z suszarnią A-400 pozwalają przekształcić odpady produkcyjne czy rolnicze w ekologiczny i opłacalny produkt opałowy jakim jest brykiet z biomasy.

Dane techniczne

Łączna moc silników elektrycznych: 27,5 kW

Wydajność: do 250–350 kg/h

Średnica brykietu: 50 mm

Typ brykietu: okrągły cylinder bez otworów

Długość brykietu: dowolna

Masa: 2800 kg

Potrzebujesz więcej informacji o tym urządzeniu?

Skontaktuj się z nami – doradzimy najlepsze rozwiązanie dla Ciebie!

Kontakt z nami