Maszyna do czyszczenia ziarna (separator) MC-500

- Kod produktu: mc-500

Opis

Maszyna do czyszczenia ziarna MC-500, zwana separatorem, służy do skutecznego usuwania zanieczyszczeń z nasion. Urządzenie przeznaczone jest do użytku zarówno w małych, jak i dużych gospodarstwach rolnych.

Operator może indywidualnie dostosować wielkość frakcji oraz ładować różne rodzaje zbóż, takie jak żyto, pszenica, słonecznik, kukurydza, rośliny strączkowe czy ziarna kawy.

Istnieje możliwość testu tej maszyny na Twoim surowcu u nas w magazynie!

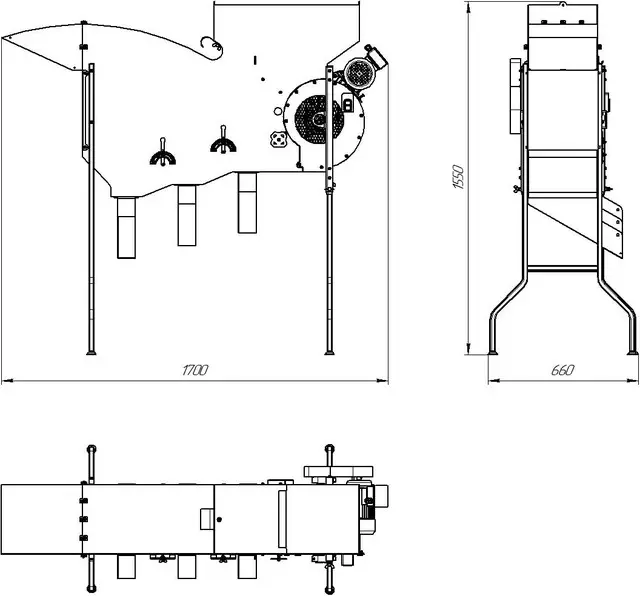

Rysunek techniczny:

Zasada działania

Zasada działania separatora opiera się na podawaniu ziarna do leja odbiorczego, gdzie rozkłada się równomiernie i przepływa do komory separacyjnej pod wpływem własnego ciężaru. Pod wpływem intensywnego przepływu powietrza najpierw oddzielane są ciężkie zanieczyszczenia i kamienie, które trafiają do pierwszej frakcji. Oczyszczone ziarno przechodzi na następną tacę, natomiast pozostałe zanieczyszczenia i uszkodzone ziarna są przenoszone przez strumień powietrza na ostatnią tacę. Lekkie zanieczyszczenia i pyły są usuwane przez wylot powietrza.

Dzięki kalibracji i separacji masowej, ziarno jest przygotowywane do siewu, co pozwala wyselekcjonować najbardziej kompletne części, gwarantując zdrową część zarodkową. Proces ten zwiększa równość ziarna, zmniejsza ilość potrzebnego materiału siewnego oraz podnosi plon.

Czyszczenie wstępne ma na celu odpylenie i częściowe usunięcie nieziarnistych odpadów, co przyspiesza przygotowanie ziarna do dalszej obróbki i tymczasowego składowania.

Film: Maszyna do czyszczenia ziarna MC-500:

Zastosowanie separatora do ziaren MC-500

Maszyna do czyszczenia nasion znajduje zastosowanie w gospodarstwach rolnych, które zajmują się dystrybucją zbóż lub innego rodzaju ziaren. Separator do nasion sprawdzi się zarówno w dużych przemysłowych uprawach, jak i małych lokalnych działalnościach agrarnych.

Prosta w obsłudze maszyna nie wymaga specjalnych kwalifikacji i może być obsługiwana z powodzeniem przez jedną osobę.

Potrzebujesz więcej informacji o tym urządzeniu?

Skontaktuj się z nami – doradzimy najlepsze rozwiązanie dla Ciebie!

Kontakt z nami