Aerodynamiczna Suszarnia SA-600 PRO

- Kod produktu: SA-600-PRO

Opis

Suszarnia SA-600 Pro to sprawdzona maszyna stworzona z myślą o suszeniu różnego rodzaju materiałów roślinnych w drobnej postaci - trocin, wiórów, słomy, czy odpadów zbożowych. Najczęściej wykorzystuje się ją wtedy, gdy trzeba przygotować surowiec do robienia pelletu, brykietu albo jakiejś innej obróbki.

W porównaniu do prostszego modelu SA-600 została rozbudowana o istotną nowość - automatyczny palnik na pellet. Kontroluje własny tryb pracy, samoczynnie się odpala, dozuje granulki i reguluje temperaturę. Dzięki temu obsługa wymaga mniejszego zaangażowania, a urządzenie może przez pewien czas funkcjonować w trybie niemal autonomicznym.

Suszarnia opiera się na prostym, lecz skutecznym mechanizmie - materiał przemieszcza się przez system rurociągów, którymi przepływa gorące powietrze. Pod wpływem odpowiednio dobranej temperatury wilgoć z powierzchni surowca szybko paruje, a wilgoć z jego wnętrza stopniowo przemieszcza się na zewnątrz. Taki proces zapewnia bezpieczne i wydajne odwadnianie. Jako źródło ciepła można wykorzystać piec murowany lub palnik na biomasę, co pozwala utrzymać optymalną temperaturę roboczą. Urządzenie doskonale współpracuje z liniami produkcyjnymi do pelletu.

W połączeniu z linią do produkcji pelletu tworzy kompletny zestaw dla producentów tego typu paliwa. Może być połączona np. z linią serii LDG.

Istnieje możliwość testu tej maszyny na Twoim surowcu u nas w magazynie!

Film: Produkcja pelletu z trociny sosnowej | Linia 25 kW + Suszarnia SA-600

Film: Linia do produkcji pelletu LDG-4000 KOMBI + Suszarnią Aerodynamiczną SA-600 | Wydajność - 500 kg/h.

Film: Linia do Produkcji Pelletu LDG-4000 MAX + Suszarnia SA-600

Zawartość zestawu

Aerodynamiczna suszarnia SA-600 składa się z następujących części:

1. Piec (murowany z 700 cegieł szamotowych)

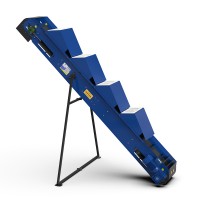

2. Kalibrator-Podajnik KPS-600

3. System rurociągów

4. Wentylator promieniowy przeciwpyłowy

5. Cyklon

6. Panel sterowania

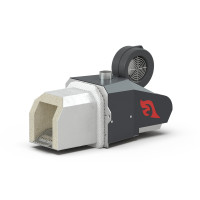

7. Palnik Domna 350 ze ślimakiem oraz panelem sterującym

Cegła do pieca nie wchodzi w skład zestawu!

Elementy są dostarczane osobno, do montażu na miejscu.

Nasze suszarnie aerodynamiczne dostarczane są w stanie rozebranym, co ułatwia transport i pozwala optymalnie wykorzystać przestrzeń ładunkową. Montaż urządzenia to proces wymagający precyzji i doświadczenia. Dlatego zalecamy kontakt z naszym specjalistą ds. obsługi klienta przed rozpoczęciem instalacji. Profesjonalne wsparcie techniczne pomoże uniknąć potencjalnych problemów i zapewni prawidłowe uruchomienie suszarni, co bezpośrednio przekłada się na jej wydajność i długotrwałą pracę.

Automatyczne Palniki na pellet (DOMNA-250 oraz DOMNA-350) są również kompatybilne z suszarniami aerodynamicznymi SA-400 i SA-600 naszej produkcji. Żeby zainstalować taki palnik wystarczy tylko wymienić drzwi w istniejącym piecu.

Film: Linia do produkcji pelletu LDG-4000 KOMBI + Suszarnią Aerodynamiczną SA-600 | Wydajność - 500 kg/h.

Zalety suszarni do trocin SA-600 PRO

- Uniwersalność – pozwala na suszenie rozmaitych materiałów roślinnych, w tym trocin (iglastych i liściastych), wiórów, słomy oraz resztek zbożowych

- Wysoka wydajność – suszenie nawet do600 kg/h, co odpowiada wymaganiom zakładu przemysłowego

- Efektywne suszenie – szybkie, precyzyjne, jednoliteodprowadzanie wilgoci z lekkich i rozdrobnionych surowców (z poziomu 60% do 6-12%), dzięki czemuznacząco skraca się czas przygotowania materiału do kolejnych etapów obróbki

- Łatwa eksploatacja – po pierwszym ustawieniufunkcjonowanie jest w dużej mierze automatyczne; tablica kontrolna i systemy bezpieczeństwa umożliwiajądokładne monitorowanie procesu suszenia

- Ekonomiczność energetyczna – suszarka charakteryzuje się niskim zużyciem energii dzięki połączeniu z piecem, coobniża wydatki

Gratis: laserowy termometr cyfrowy i tawotnica do smarowania

156,2 kB

Zastosowanie suszarni rurowej do trocin SA-600 PRO

Suszarnia aerodynamiczna do trocin SA-60 PRO sprawdzi się wszędzie tam, gdzie wymagana jest szybka i efektywna przeróbka pozostałości roślinnych. Maszyna znajduje zastosowanie w sektorze drzewnym i energetycznym, a także w gospodarstwach rolnych oraz zakładach produkujących pellet.

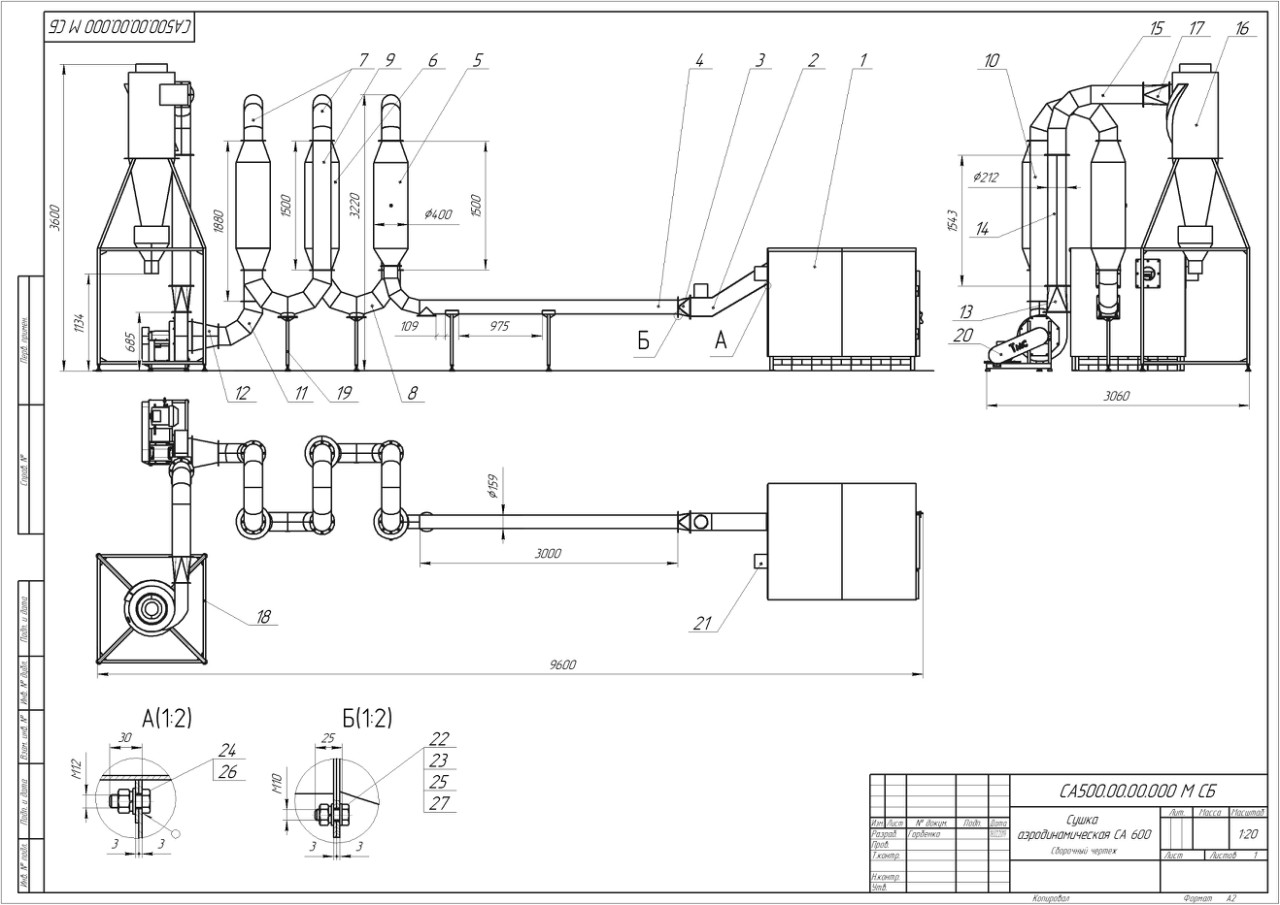

Parametry techniczne aerodynamicznej suszarni do Trocin SA-600 PRO

- długość rurociągu – 25m

- bunkier kalibratora może pomieścić 1 m3 trocin

- 3 poszerzenia;

- moc wentylatora – 5.5 kw

- wydajność – 600 kg/h

- system "Cyklon"

- początkowa wilgotność surowca do 60%

- Wydajność do 600 kg / h.

- Dł. 9600 mm. x Wys. 3600 mm. x Sz. 3060 mm, waga: 1000 kg.

- Cała linia z suszarnią : D.13000 mm. x W. 3500 mm. x SZ 4000 mm, waga: 2300 kg.

Przetwarzane surowce:

- trociny;

- zrębka drewniana;

- słoma;

- odpady zbożowe oraz wiele innych materiałów.

Etapy pracy suszarni do trocin:

- Do zbiornika podawczego wsypuje się surowiec o pojemności 1 m³, który jest przesiewany siatką wibracyjną nad zbiornikiem

- Jednocześnie do rurociągu wtłaczane jest gorące powietrze, często nazywane „czynnikiem suszącym”.

- Razem z czynnikiem suszącym surowiec transportowany jest przez rurociąg.

- Pod wpływem wysokiej temperatury wilgoć z powierzchni surowca odparowuje, a wewnętrzna wilgoć przemieszcza się ku powierzchni.

- Ten proces oraz odpowiednio dobrana temperatura zapobiegają zapłonowi cząstek.

Potrzebujesz więcej informacji o tym urządzeniu?

Skontaktuj się z nami – doradzimy najlepsze rozwiązanie dla Ciebie!

Kontakt z nami