ZPK-1 - linia do powlekania i aromatyzowania karmy dla zwierząt

- Kod produktu: ZPK-1

Opis

ZPK-1 to nowoczesna linia przeznaczona do powlekania i aromatyzowania suchej karmy dla zwierząt – zarówno domowych (psów i kotów), jak i gospodarskich (ryb, kóz, bydła). Urządzenie zostało zaprojektowane z myślą o szerokim wachlarzu zastosowań w zależności od różnych wymagań produkcyjnych.

Zestaw składa się z trzech modułów: bębna obrotowego z dyszami do rozpylania płynów, podajnika UWD-2 do suchych składników i bębna mieszającego.

Dzięki temu możliwa jest praca niezależna (np. tylko z płynami lub tylko z suchymi dodatkami) albo pełna – łącząca procesy w jednej linii.

Precyzyjna regulacja parametrów (obroty, dozowanie, kąt nachylenia) gwarantuje wysoką jakość i powtarzalność efektów. System sprawdza się jako uzupełnienie takich urządzeń jak ekstruder paszowy, ekstruder do karmy dla psów, ekstruder do karmy dla kotów czy ekstruder do produkcji karmy dla ryb i bydła.

Linia do powlekania i aromatyzowania karmy dla zwierząt składa się z kilku jednostek urządzeń, które pełnią określone funkcje i połączone są w jedną linię technologiczną. Głównym celem kompleksu jest dozowanie oraz równomierne mieszanie wilgotnych i suchych składników z produktem. W jego skład wchodzą trzy podstawowe elementy: bęben nr 1, układ podawania suchych i płynnych składników UWD-2 oraz bęben nr 2. Zestaw wyposażony jest w panel sterowania całym kompleksem.

- Bęben nr 1 – wprowadzane są do niego płynne składniki, takie jak olej czy tłuszcz. Dzięki regulowanej prędkości obrotowej bębna, możliwości ustawienia kąta nachylenia oraz zaprogramowanemu podawaniu cieczy, produkt pokrywany jest równomiernie dodatkami. To umożliwia zachowanie receptury i zapewnia lepszą przyczepność suchych składników w kolejnym etapie.

- Układ podawania UWD-2 – kluczowy element linii. Za pomocą panelu sterowania konfiguruje się program dozowania dodatków płynnych i suchych. Mobilna konstrukcja umożliwia pracę z jednym lub dwoma bębnami oraz elastyczne dozowanie (tylko płynne, tylko suche lub oba jednocześnie). W kompleksie DPP równolegle pracują dwa bębny: płyn dodawany jest do bębna nr 1, a suche składniki aplikowane są w korycie podczas transportu produktu do bębna nr 2.

- Bęben nr 2 – dzięki specjalnej konstrukcji i geometrii bębna zapewnia delikatne, równomierne i wysokiej jakości mieszanie suchych dodatków z produktem. Poprzednie zwilżenie zwiększa adhezję. Regulacja obrotów, kąta nachylenia oraz duża średnica bębna pozwalają optymalnie dobrać tryby mieszania i wyładunku produktu.

Istnieje możliwość testu tej maszyny na Twoim surowcu u nas w magazynie!

Główne zalety linii do aromatyzowania karmy dla zwierząt ZPK-1

- Możliwość powlekania zarówno płynami (oleje, tłuszcze), jak i składnikami sypkimi (przyprawy, witaminy)

- Praca w trybie pełnym lub modułowym – gwarantuje elastyczność

- Precyzyjne dozowanie: dokładność do 0,2%

- Duże zbiorniki: 50 l na płyny i 55 l na składniki suche

- Cicha i energooszczędna praca – pobór mocy do 1 kW

- Zgodność z ekstruderami do karmy dla zwierząt serii ESK i suszarniami do karmy ST-15

- Idealna dla małych i średnich producentów karmy dla zwierząt

Zastosowanie

ZPK-1 to niezawodne urządzenie do produkcji karmy dla psów i kotów, a także zwierząt gospodarskich, w tym ryb, kóz i bydła. W zestawie z ekstruderami paszowym z serii ESK i suszarniami do karmy dla zwierząt, stanowi integralny element kompletnej linii technologicznej.

Dzięki dokładnej kontroli nad procesem powlekania, zestaw umożliwia wzbogacenie karmy w wartościowe składniki, poprawia smak oraz wydłuża trwałość gotowego produktu. ZPK-1 gwarantuje najwyższą jakość i rozsądne koszta produkcji.

Zastosowanie kompleksu drażowania:

- przekąski i snacki,

- krakersy i inne wypieki,

- gotowe dania,

- popcorn,

- orzechy,

- kawa i herbata,

- karmy i przysmaki dla zwierząt,

- ściółki dla zwierząt,

- oraz inne produkty.

Parametry techniczne:

- Wydajność: od 100 do 1000 l/h

- Prędkość obrotowa bębnów (optymalna): 8 obr./min

- Pojemność zbiornika na płyny: 50 l

- Pojemność zbiornika na suche składniki: 55 l

- Dokładność dozowania: 0,2 %

- Pobór mocy: max 4,14 kW (380-400 V)

- Waga: 725 kg

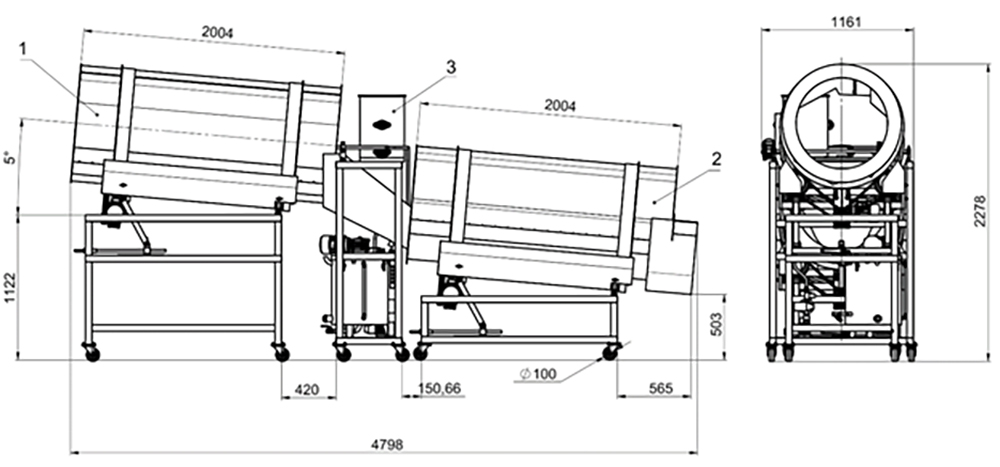

Rysunek techniczny:

Potrzebujesz więcej informacji o tym urządzeniu?

Skontaktuj się z nami – doradzimy najlepsze rozwiązanie dla Ciebie!

Kontakt z nami