Линия для производства пеллет LDG-2000 (KOMBI)

Доступные варианты

- Модель: LDG-2000_KOMBI

Описание

Линия по производству пеллет и комбикормов LDG-2000 KOMBI от компании TechnoMaszBud, основанная на грануляторе PRIME-200, — это высокоэффективная и универсальная технологическая линия, предназначенная для производства топливных пеллет и гранулированных кормов для животных.

Оборудование разработано для фермерских хозяйств, кормовых и столярных предприятий, а также лесопилок, которые ищут эффективные и экономичные решения для переработки древесных отходов и биомассы.

Эта линия отличается от модели LDG-3000 KOMBI меньшим гранулятором мощностью 11 кВт. Линия гранулирования может использоваться как для производства пеллет и гранулированных кормов для собственного использования, так и для бизнеса.

ВОЗМОЖНО ПРОТЕСТИРОВАТЬ ЭТУ МАШИНУ НА ВАШЕМ СЫРЬЕ В НАШЕМ СКЛАДЕ!

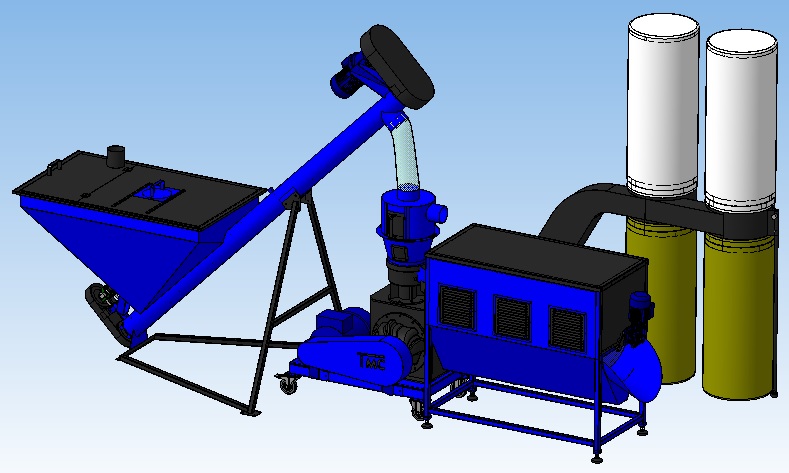

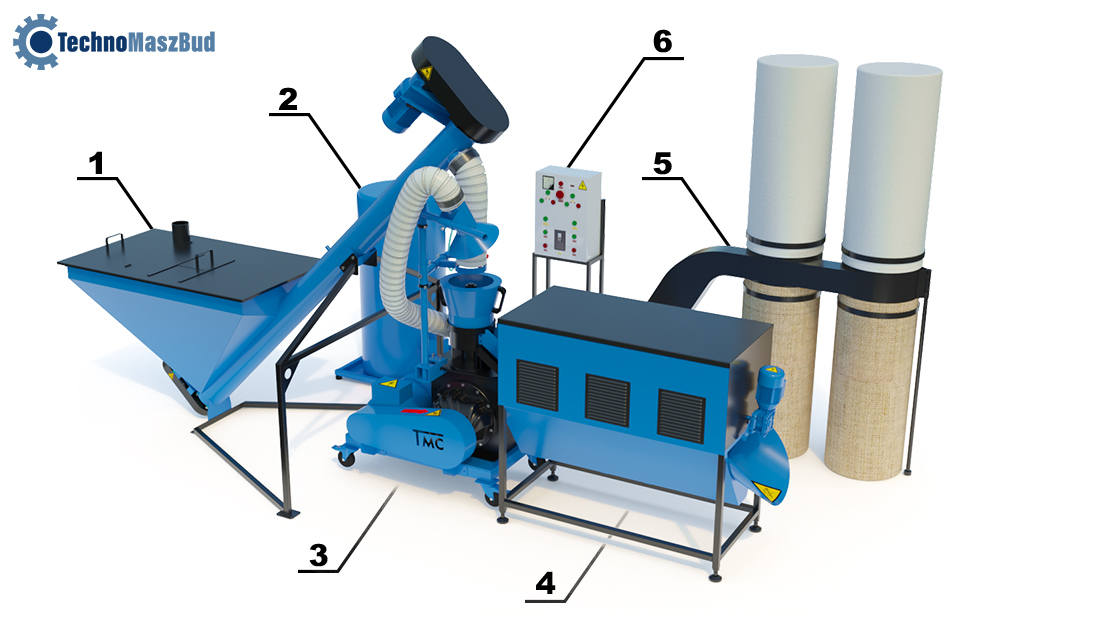

Высокую производительность и надёжность линии обеспечивает взаимодействие нескольких ключевых компонентов – шнекового питателя, системы увлажнения, гранулятора PRIME-200, охладителя, системы отсоса и интегрированной панели управления. Благодаря этому полностью собранная линия LDG-2000 KOMBI отличается стабильной работой, простым управлением и возможностью работы с разными типами сырья.

Для вашего удобства мы можем не только подобрать линию под ваши требования, но и помочь с её установкой, запуском и достижением ожидаемого результата!

Видео: Линия по производству пеллет LDG-2000 KOMBI PRO | 18 кВт, до 220 кг/ч.

Видео: Как это работает | Тест производительности. Линия по производству пеллет LDG-3000 KOMBI вместе с сушилкой:

Видео: Универсальная мини-линия для производства пеллет и комбикормов:

В состав линии LDG-2000 KOMBI входит:

Данный модуль потребляет 1,5 кВт электроэнергии, оснащён плавной регулировкой скорости подачи сырья с помощью преобразователя частоты.

2. Система увлажнения:

Основные элементы системы увлажнения: клапан, насос, резервуар объёмом 100 л, форсунка. Система установлена на стойке над рабочей частью, что позволяет точно добавлять необходимое количество влаги в процессе гранулирования. Потребляемая мощность — 0,37 кВт.

3. Надёжный гранулятор PRIME-200:

Гранулятор PRIME-200 легко справляется с разными видами сырья: до 150 кг/час на пеллетах из опилок и до 350 кг/час на комбикорме. Подвижные ролики обеспечивают высокую износостойкость и надёжность процесса.

4. Калибратор-охладитель для гранул/пеллет KC-100:

Этот модуль служит для дополнительного охлаждения готовой продукции, удаления пыли и крошек. Мощность этого узла — 0,12 кВт.

5. Закрытая система отсоса SO-2:

Это устройство с помощью вентилятора обеспечивает циркуляцию воздуха, необходимую для охлаждения гранул и сбора калиброванных остатков сырья и пыли в мешках, установленных на нем. Мощность — 1,5 кВт.

6. Панель управления:

Компактные размеры и встроенная система охлаждения автоматики делают панель управления надёжной и удобной для установки рядом с производственной линией. В панели имеется амперметр и термозащита для каждого двигателя линии

Ленточный транспортер не входит в комплект!

Кабели для подключения линии не входят в комплект

Видео: Линия по производству пеллет | Как работает, из чего состоит:

Видео: Как работать на линии производства пеллет серии LDG:

Производительность линии по производству пеллет LDG-2000 KOMBI:

- древесные отходы — до 150 кг/ч;

- солома — до 150 кг/ч;

- комбикорм — до 350 кг/ч;

- подсолнечная лузга — до 150 кг/ч;

Самое главное — соблюдение требований по фракции и уровню влажности обрабатываемого сырья.

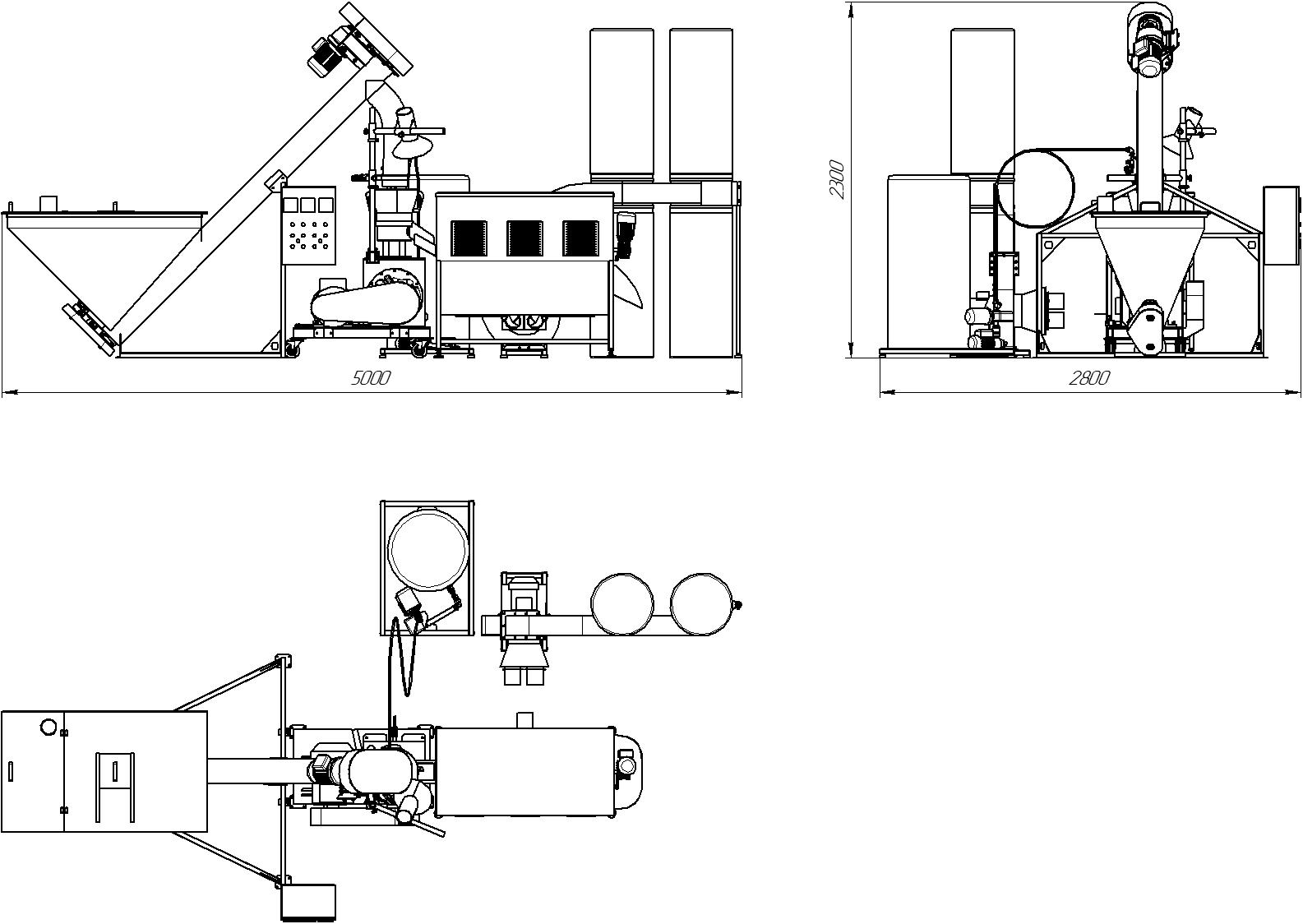

Технический чертёж:

Преимущества линии LDG-2000 KOMBI

- Высокая производительность – до 350 кг корма или 150 кг пеллет в час.

- Интегрированная и компактная конструкция – все узлы работают в одной линии, что упрощает обслуживание и монтаж.

- Универсальность сырья – линия перерабатывает опилки, стружку, солому, лузгу, зерно, сельскохозяйственные отходы и даже пластики.

- Энергосбережение – оптимизированная работа двигателей позволяет снизить энергопотребление.

- Персонализация – возможность дооснащения линии дополнительным оборудованием: транспортеры, дробилки, сушилки и др.

- Безопасность работы – системы защиты и надёжная конструкция гарантируют стабильную и безопасную эксплуатацию.

- Экономичность и экологичность – эффективная переработка древесных и сельскохозяйственных отходов снижает издержки и обеспечивает дополнительный доход.

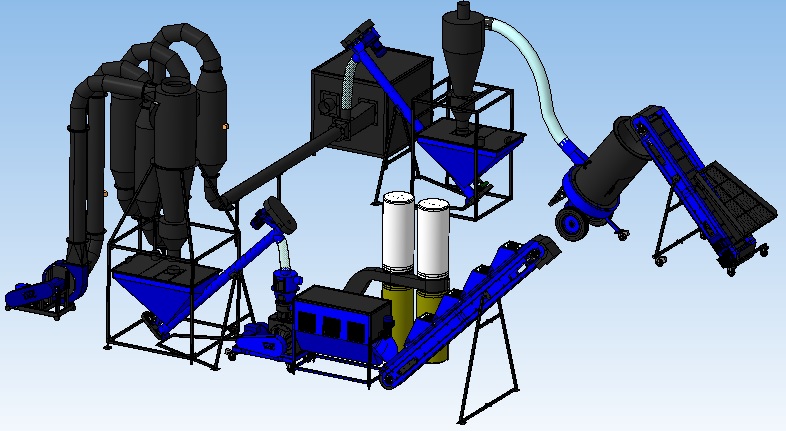

Линия гранулирования может использоваться как отдельная производственная единица, а также быть оснащена дополнительным оборудованием для большей автоматизации производства пеллет и гранулированных кормов:

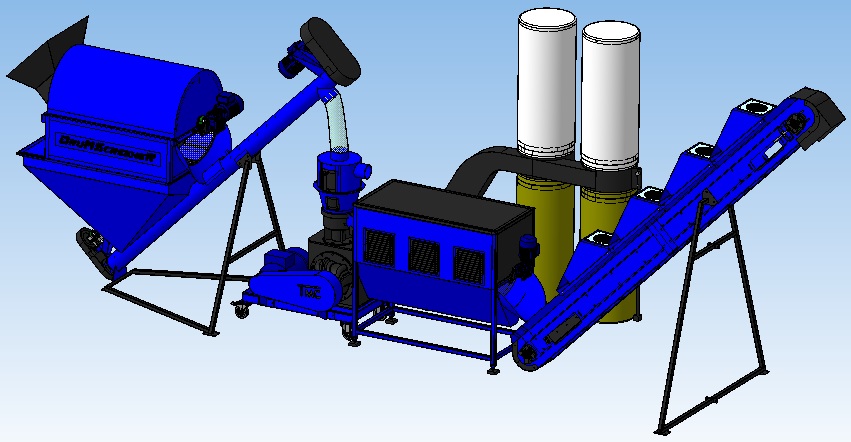

PK-2 (транспортер-калибратор) – основная задача: подача и калибровка сырья;

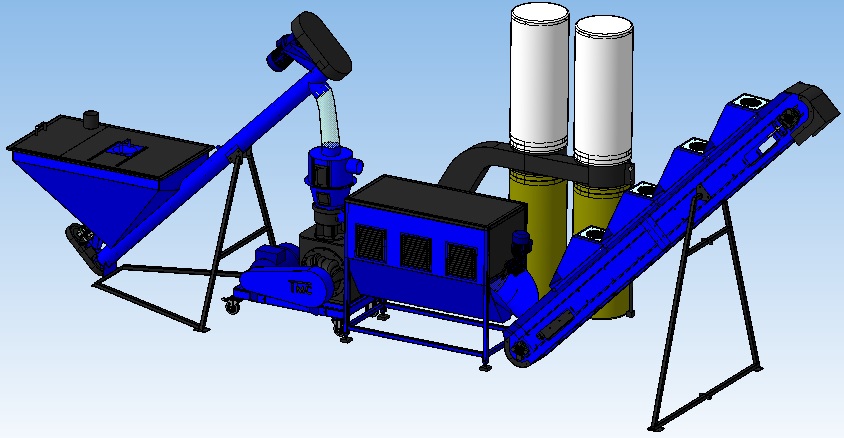

PT-250 (ленточный транспортер) – основная задача: подача и охлаждение сырья;

PT-500 (ленточный транспортер) – основная задача: подача и охлаждение сырья;

RD-500 (дробилка) – основная задача: измельчение сырья (солома, сено, стружка и др.) до нужной фракции;

KPS-400 (калибратор-питатель) – основная задача: калибровка сырья и равномерная подача;

KC-200 (удлинённый калибратор-охладитель) – охлаждение и калибровка готовых гранул;

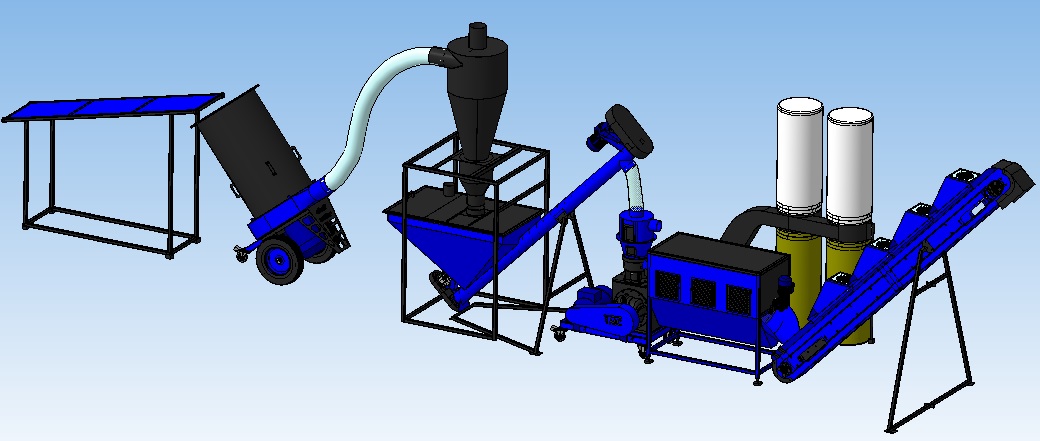

SA-400 (аэродинамическая сушилка с калибратором) – калибровка и сушка сырья.

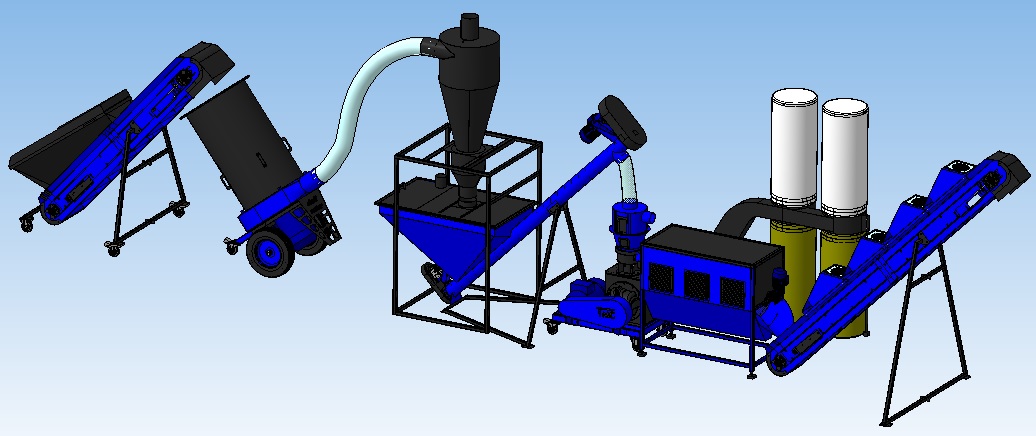

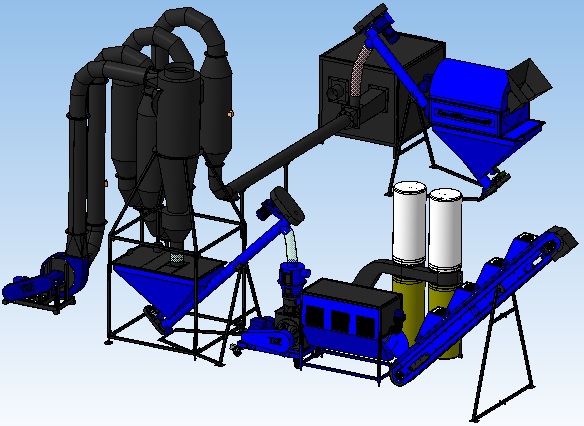

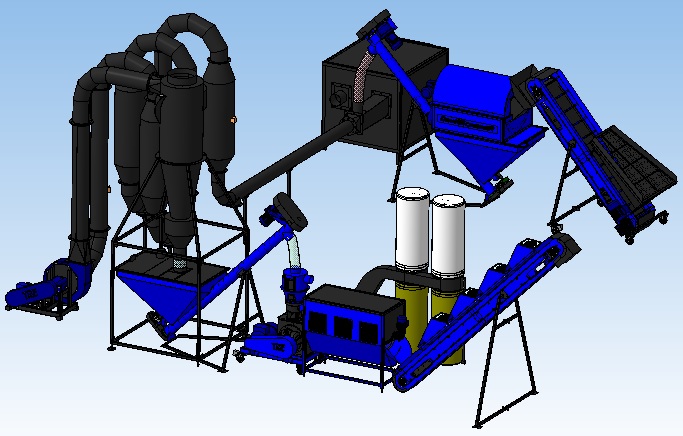

Возможные комплектации линии по производству пеллет:

1. Линия LDG-2000 KOMBI 14 кВт

2. Линия LDG-2000 KOMBI + Ленточный транспортер PT-500 с вентиляторами

3. Линия LDG-2000 KOMBI с калибратором (Сепаратор крупных фракций, где происходит отсев веток, коры, крупных кусков древесины и камней) + Ленточный транспортер PT-500 с вентиляторами

4. Линия LDG-2000 KOMBI + Ленточный транспортер PT-500 с вентиляторами + Дробилка RD-500 с циклоном

5. Линия LDG-2000 KOMBI + Ленточный транспортер PT-500 с вентиляторами + Дробилка RD-500 с циклоном + Ленточный питающий калибратор PT-1000

6. Линия LDG-2000 KOMBI + Ленточный транспортер PT-500 с вентиляторами + Аэродинамическая сушилка для опилок SA-400

7. Линия LDG-2000 KOMBI + Ленточный транспортер PT-500 с вентиляторами + Аэродинамическая сушилка для опилок SA-400 + Ленточный калибратор-питатель PT-1000

8. Линия LDG-2000 KOMBI+ Ленточный транспортер PT-500 с вентиляторами + дробилка RD-500 с циклоном + ленточный калибратор-питатель PT-1000 + аэродинамическая сушилка для опилок SA-400

Какое сырьё можно перерабатывать на линии LDG-2000?

Линия для производства пеллет LDG-2000 предназначена для пеллетирования опилок, стружки, пыли, соломы, торфа, пластика и других материалов. Для получения гранул для животных можно использовать такие сырьё, как зерно, отходы зерновых, корм, сено, шрот.

Для получения наилучшего качества пеллет и достойной производительности готового продукта оптимальная фракция должна быть менее 6 мм.

Технические данные LDG-2000 (KOMBI)

Суммарная мощность — 14 кВт

Габариты — 500х280х230 см,

Вес — 750 кг.

Линия может быть установлена даже в небольшом помещении, что дополнительно снижает расходы на покупку или аренду. Кроме того, у нас можно заказать запасные части, например комплект матриц с отверстиями 2 мм, 3 мм, 4 мм, 5 мм, 6 мм и 8 мм — это даёт возможность получать гранулы различного размера.

Техническая поддержка и обучение

Вместе с поставкой оборудования мы обеспечиваем профессиональную техническую поддержку, помощь в установке и запуске, а также обучение персонала. Это позволяет пользователю быть уверенным в правильной эксплуатации оборудования и максимальной эффективности в повседневной работе.

Применение

Линия LDG-2000 KOMBI находит широкое применение в фермерских хозяйствах, лесопильных и столярных цехах, кормовых заводах и компаниях, занимающихся производством биотоплива.

Модель даёт возможность производить:

- топливные пеллеты из опилок, стружки, щепы и биомассы,

- гранулированные корма однородной структуры с высокой усвояемостью,

- пластиковые гранулы, используемые, например, для производства труб.

Благодаря своей универсальности и компактности LDG-2000 KOMBI — это идеальное решение как для собственных производственных нужд, так и для бизнеса, ориентированного на продажу пеллет и гранулированных кормов.

Видео: Производство пеллет из щепы | Линия 25 кВт + сушилка:

Видео: Линия по гранулированию соломы | Полный цикл пеллетирования от тюка до упаковки:

Нужна дополнительная информация об этом оборудовании?

Свяжитесь с нами — мы подберём для вас оптимальное решение!

Связаться с нами