Linia do granulacji LDG-4000 (MAX+)

Dostępne opcje

- Kod produktu: LDG-4000_MAX+

Opis

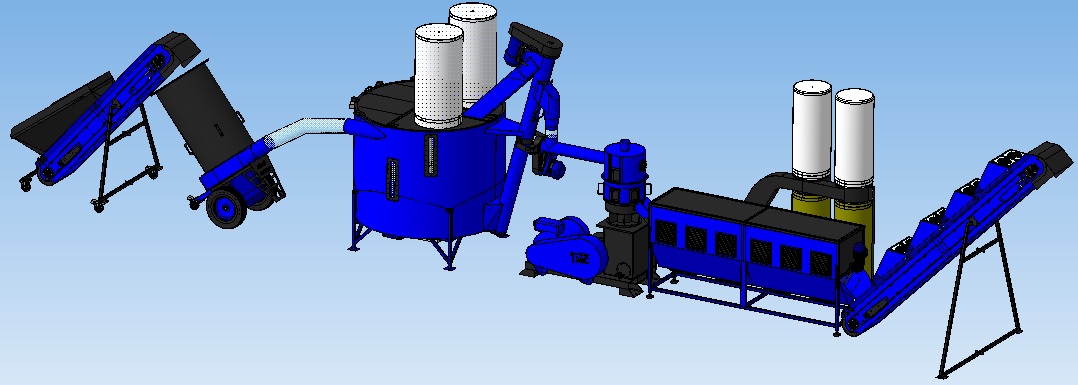

Linia do produkcji pelletu LDG‑4000 MAX+ to nowoczesne i wydajne rozwiązanie technologiczne, które umożliwia granulację różnorodnych surowców. Maszyna przeznaczona jest do wytwarzania pelletu o średnicy od 2 mm do 8 mm, co pozwala na produkcję zarówno paliwowego pelletu drzewnego, jak i paszy granulowanej dla zwierząt. Wydajność linii sięga do 500 kg/h przy produkcji paszy oraz do 450 kg/h w przypadku pelletu drzewnego, dzięki czemu sprawdza się w zakładach rolnych, stolarskich, tartacznych i energetycznych.

ISTNIEJE MOŻLIWOŚĆ PRZEPROWADZENIA TESTU TEJ MASZYNY NA TWOIM SUROWCU U NAS W MAGAZYNIE!

Linia do produkcji pelletu LDG-4000 MAX+ to rozbudowana wersja linii z serii LDG-4000 produkcji TechnoMaszBud.

W porównaniu z modelem KOMBI/MAX, zestaw ten został wyposażony w podajnik PS-1500 o pojemności 1,5 m³ który równomiernie dostarczają surowiec do peleciarki PRIME-400, zapewniając stabilną i wydajną pracę całego układu. PS-1500 pełni również funkcję cyklonu z wbudowanymi workami odpylającymi. Linia umożliwia podłączenie rozdrabniacza oraz młyna bijakowego.

Film: Produkcja pelletu z wiórów sosnowych | Linia do produkcji pelletu LDG-4000 (MAX+)

W skład linii LDG-4000 MAX+ wchodzą:

1. Podajnik ślimakowy PS-1500:

Zespół ten zużywa 2,6 kW energii elektrycznej i pełni funkcję cyklonu. Głównym zadaniem PS-1500 jest podawanie surowca do peleciarki. Pojemność zbiornika: 1,5 m³.

2. System nawilżania:

Główne elementy układu to zawór, pompa, zbiornik na wodę o pojemności 100 litrów oraz dysza. System jest podłączony do stojaka nad częścią roboczą, co pozwala na precyzyjne dodanie wymaganej ilości wilgoci podczas procesu granulacji. Pobór mocy: 0,37 kW.

3. Niezawodna peleciarka PRIME-400:

Granulator PRIME-400 z łatwością przetwarza różne rodzaje surowców, osiągając wydajność do 650 kg/h przy produkcji pelletu z trocin oraz do 700 kg/h przy granulacji paszowej.

4. Wydłużony kalibrator–chłodnica do granulatu/pelletu KC-200:

Urządzenie to pełni funkcję dodatkowego chłodzenia produktu, ponieważ pellet nagrzewa się w czasie procesu peletowania. Dodatkowo usuwa kurz i drobne okruchy za pomocą specjalnego bębna. Pobór mocy: 0,12 kW.

5. Zamknięty układ odciągowy SO-2:

Urządzenie to, dzięki zastosowaniu wentylatora, zapewnia cyrkulację powietrza niezbędną do schłodzenia granulek oraz zbierania resztek surowca i pyłu do pojemników w postaci worków zamontowanych na konstrukcji. Moc: 1,5 kW.

6. Panel sterowania:

Kompaktowe wymiary oraz wbudowany system chłodzenia automatyki sprawiają, że panel sterowania jest niezawodny i wygodny w montażu w pobliżu linii produkcyjnej. Panel wyposażony jest w amperomierz oraz zabezpieczenie termiczne każdego silnika w linii.

Przenośnik taśmowy nie wchodzi w skład zestawu.

Kable do podłączenia linii również nie są zawarte w zestawie.

Wydajność Linii do produkcji pelletu LDG-4000 MAX+:

- odpadów drzewnych – do 650 kg/h,

- słomy – do 550 kg/h,

- paszy – do 700 kg/h,

- łuski słonecznika – do 550 kg/h.

Kluczowe znaczenie dla osiągnięcia optymalnej wydajności ma odpowiednia frakcja oraz wilgotność materiału wsadowego.

Rodzaje linii LDG-4000 MAX+:

Dostępnych jest kilka konfiguracji linii LDG‑4000 MAX+, różniących się m.in. zakresem automatyzacji oraz dodatkowymi elementami, jak przenośniki, rozdrabniacze, suszarnie czy kalibratory. Klient ma możliwość wyboru rozwiązania najlepiej dopasowanego do swoich potrzeb – od wersji podstawowej po rozbudowane systemy z pełnym układem odciągowym i modułami wspomagającymi proces granulacji.

Linię do produkcji pelletu LDG-4000 MAX+ można rozbudować o dodatkowe moduły:

PK-2 (przenośnik-kalibrator), urządzenie przeznaczone do podawania i kalibracji surowca, zapewniające jego równomierne przygotowanie przed dalszym etapem produkcji.

PT-500 (przenośnik taśmowy), służy do transportu oraz chłodzenia surowca po procesie granulacji.

RD-500 (rozdrabniacz), przeznaczony do mielenia surowców takich jak słoma, siano, wióry i inne materiały włókniste do wymaganej frakcji.

MB-500 (młyn bijakowy), stosowany do rozdrabniania zrębki i kory na frakcję odpowiednią do dalszego procesu peletowania.

Przykładowe zestawy:

1. Linia LDG-4000 MAX+

2. Linia LDG-4000 MAX+ 43 Kw + Przenośnik Taśmowy PT-500 z wentylatorami

3. Linia LDG-4000 MAX+ z bunkrem kalibratorem (wyposażony w siatkę do odfiltrowania kory, kawałków drewna, gałęzi, śmieci) 43 Kw + Przenośnik Taśmowy PT-500 z wentylatorami

4. Linia LDG-4000 MAX+ 43 Kw + Przenośnik Taśmowy PT-500 z wentylatorami + Rozdrabniacz RD-500 (stół gratis)

5. Linia LDG-4000 MAX+ 43 Kw + Przenośnik Taśmowy PT-500 z wentylatorami + Rozdrabniacz RD-500 (stół gratis) + Podajnik-kalibrator taśmowy PT-1000.

Główne zalety linii do produkcji pelletu LDG-4000 MAX+:

- Wysoka wydajność – do 700 kg paszy lub 650 kg pelletu na godzinę

- Wszechstronność – granulacja drewna, słomy, ziaren, łusek, biomasy i tworzyw sztucznych

- Duży podajnik‑cyklon PS‑1500 zapewniający czystość i płynność podawania

- Możliwość rozbudowy i dostosowania linii do indywidualnych potrzeb

- Panel sterowania z pełnym systemem zabezpieczeń

- Kompaktowe wymiary, odpowiednie nawet do mniejszych hal

- Ekologiczne rozwiązanie – maksymalne wykorzystanie odpadów

Stabilna i bezpieczna praca dzięki kontroli każdej sekcji silnikowej

Z jakiego surowca można produkować pellet?

- trociny z drzew liściastych i iglastych,

- odpady po czyszczeniu słonecznika, kukurydzy, zbóż,

- słoma, gałęzie, łuski nasion,

- odpady z produkcji tworzyw sztucznych.

Z jakiego surowca można produkować paszę?

- ziarno i zboże,

- śruta, siano,

- mieszanki paszowe.

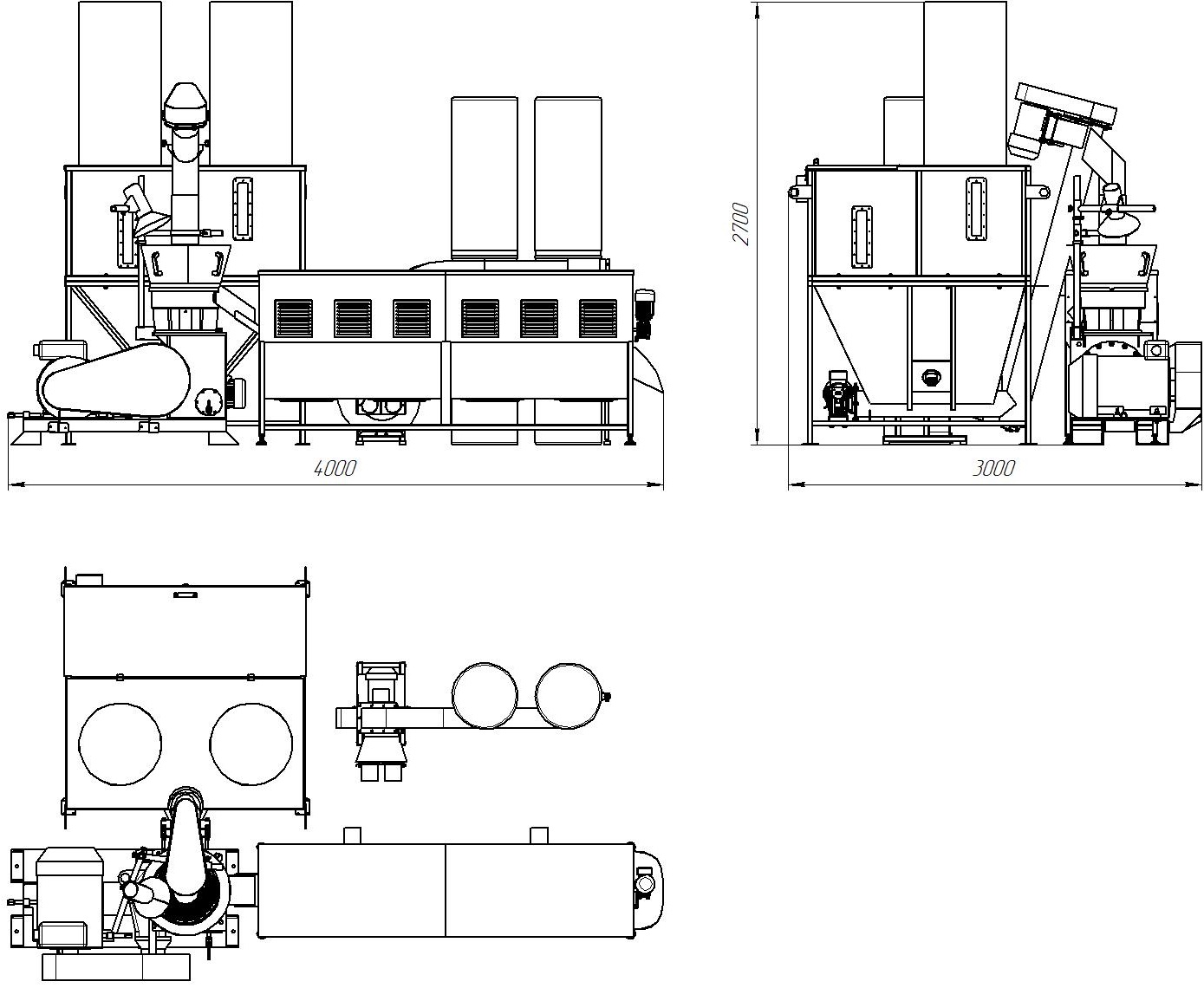

Rysunek techniczny:

Gotowe produkty, które można uzyskać za pomocą linii LDG-4000 (MAX+):

- Pellet z trocin, wiórów i zrębki,

- Pellet z biomasy roślinnej,

- Pellet paliwowy z odpadów organicznych,

- Pełnowartościowy granulat paszowy oprzyswajalności do 90%,

- Granulat z tworzyw sztucznych, wykorzystywany m.in. wprodukcji rur i komponentów technicznych.

Wsparcie techniczne i szkolenie

Wraz z dostawą zapewniamy profesjonalne wsparcie techniczne, pomoc w instalacji i uruchomieniu, a także przeszkolenie personelu. Dzięki temu użytkownik zyskuje pewność prawidłowej eksploatacji urządzenia oraz maksymalnej wydajności w codziennej pracy.

Zastosowanie

Linia do pelletu LDG‑4000 MAX+ znajduje zastosowanie w wielu branżach, w tym: produkcji pelletu opałowego z trocin, zrębków i odpadów drzewnych, granulacji słomy i biomasy rolniczej, produkcji paszy granulowanej dla zwierząt, recyklingu odpadów organicznych i tworzyw sztucznych. Linie do produkcji pelletu z serii LDG to gwarancja wydajności, wszechstronności i oszczędności – niezawodne rozwiązanie dla firm poszukujących sprawdzonej technologii do granulacji biomasy i pasz.

Linię LDG-4000 (MAX+) można eksploatować nawet w niewielkim pomieszczeniu, co pozwala znacznie obniżyć koszty inwestycji oraz wydatki związane z wynajmem lub zakupem hali produkcyjnej.

Dodatkowo oferujemy części zamienne do urządzeń, w tym zestawy matryc z otworami 2 mm, 3 mm, 4 mm, 5 mm, 6 mm i 8 mm,

co umożliwia produkcję granulek o różnej średnicy, w zależności od rodzaju surowca i przeznaczenia produktu.

Potrzebujesz więcej informacji o tym urządzeniu?

Skontaktuj się z nami – doradzimy najlepsze rozwiązanie dla Ciebie!

Kontakt z nami

Specyfikacja

Tagi:

Granulatory Linia do granulacji LDG maszyna do peletu pelleciarka peleciarka peleciarki produkcja pelletu maszyna do produkcji peletu maszynka do pelletu maszyna do robienia pelletu pelet pellet granulator linie do produkcji pelletu linie do pelletu linia do produkcji pelletu linia do pelletu prasy do pelletu