Aerodynamic Double-Circuit Sawdust Dryer SA-800

- Product Code: SA-800

Description

SA-800 Dual-Circuit Sawdust Dryer is a professional moisture removal machine for light raw materials of fine fraction, including sawdust, wood chips, straw, and grain waste. It is used during the preparation of material for pelletizing, granulating, or briquetting.

You can test this machine with your own raw material at our warehouse!

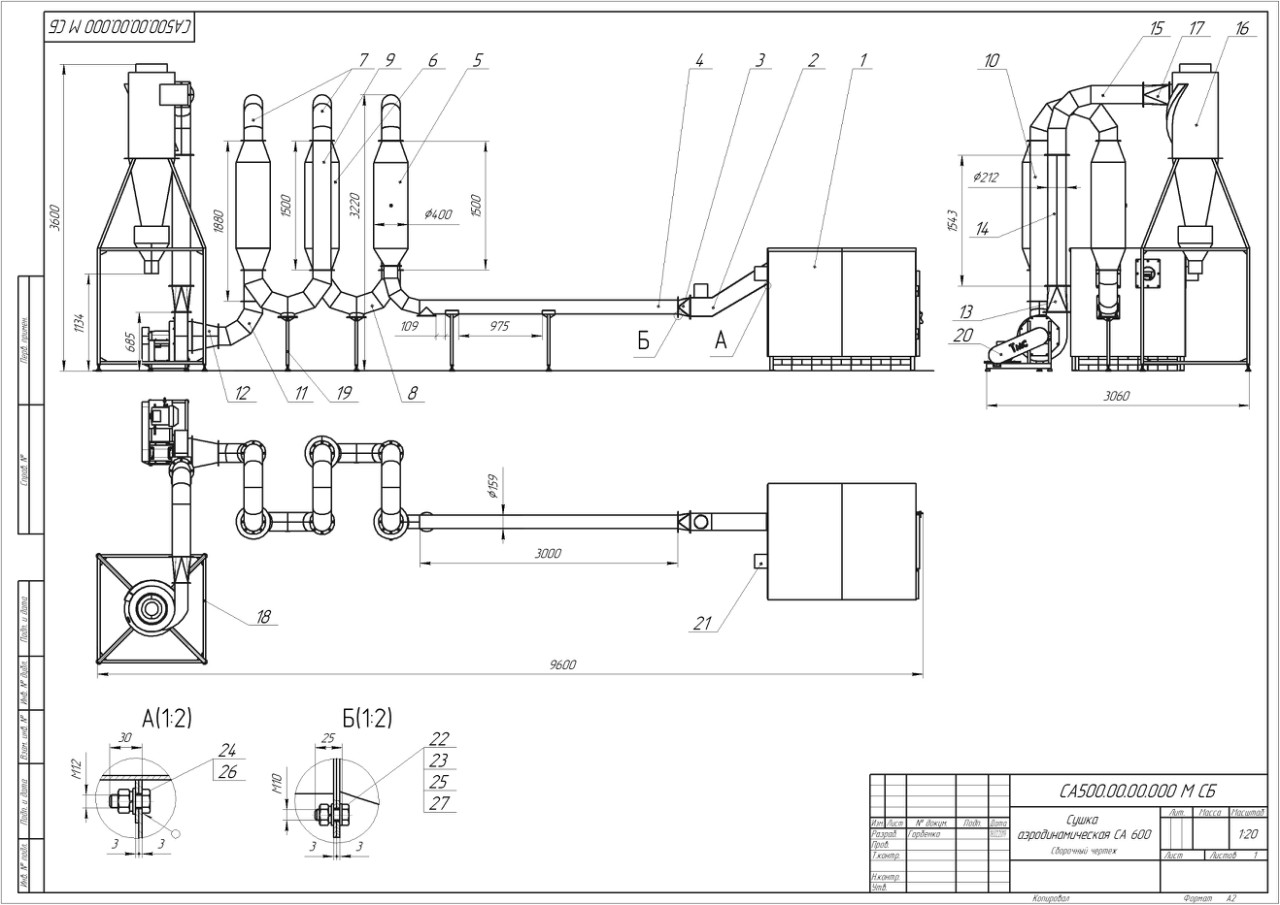

The difference between the SA-600 and SA-800 models is that the SA-800 is equipped with a second pipeline circuit, along with an additional cyclone and fan, which allows the raw material to be dried more effectively, thus increasing the dryer's efficiency.

The tubular sawdust dryer uses a simple operating mechanism: the material is dried in an aerodynamic pipeline, where a stream of hot air circulates. Under the influence of high temperature, the moisture from the surface of the raw material evaporates, while the internal moisture migrates to the surface — this process reduces the risk of ignition.

The heat source is a connected wood-fired furnace or a pellet burner, such as DOMNA-350.

The machine is the perfect complement to the LDG-3000 DUO granulation line as well as the LDG-4000 DUO.

Video: SA-800 Dual-Circuit Aerodynamic Sawdust Dryer:

Set contents

- Furnace (built from 700 fireclay bricks).

- Calibrator – KPS-600 feeder.

- Pipeline system.

- 2 anti-dust centrifugal fans.

- 2 cyclones.

- Control panel.

- BONUS — laser digital thermometer and grease gun for lubrication.

The elements are delivered separately for on-site assembly.

Bricks for the furnace are not included in the set!

Video: LDG-3000 DUO Pellet Production Line + SA-800 Dryer | Pellet Production in a Sawmill:

Advantages of the SA-800 Sawdust Dryer

- Versatility – enables drying of various plant-based materials, including sawdust (from coniferous and deciduous trees), wood chips, straw, and grain waste.

- High efficiency – drying up to 800 kg/h, which meets the needs of a production plant.

- High drying effectiveness – fast, precise, and uniform moisture removal from light and fine materials (from 60% to 6–12%), which allows you to significantly shorten the time needed to prepare the material for further processing.

- Innovative dual-circuit technology – the design minimizes the risk of material ignition thanks to temperature control and optimal airflow.

- Simple operation – after calibration, the process is partially automated; the control panel and safety sensors allow for precise drying control.

- Energy saving – the dryer uses relatively little energy due to the furnace connection, which reduces operating costs.

Bonus: laser digital thermometer and grease gun for lubrication included

156,2 kB

Applications of the SA-800 tubular sawdust dryer

SA-800 aerodynamic sawdust dryer is perfect wherever fast and efficient processing of plant waste is required. The device can be used in the wood and energy industries, as well as in agriculture and at pellet production plants.

Sawdust dryer workflow stages:

- The raw material is poured into a supply tank with a capacity of 1 m³, which is screened by a vibrating mesh above the tank.

- At the same time, hot air, often called the “drying agent,” is injected into the pipeline.

- The raw material is transported through the pipeline together with the drying agent.

- Under the influence of high temperature, moisture from the surface of the raw material evaporates, and the internal moisture moves toward the surface.

- This process and the properly selected temperature prevent particle ignition.

Need more information about this device?

Contact us – we’ll help you find the best solution!

Contact us