Select a subcategory

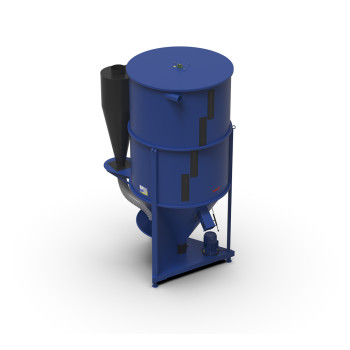

Product code: MP-300

1,717.39€

Availability: In stock

Feed mixer MP-300 is a simple and reliable device for mixing dry feed ingredients. The MP-300 allows..

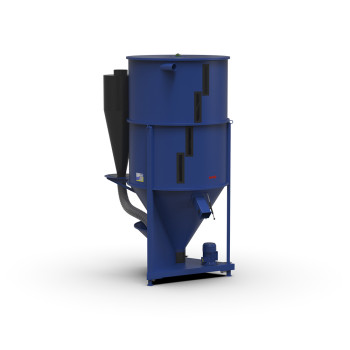

Product code: MP-450

1,780.19€

Availability: In stock

The MP-450 mixer is a compact and efficient device designed for preparing homogeneous feed mixtures...

Product code: MP-600

2,367.15€

Availability: In stock

MP-600 Feed Mixer – efficient feed mixing for your farm The MP-600 mixer is a modern and reliable d..

Product code: MP-1000

3,091.79€

Availability: In stock

MP-1000 Feed Mixer is an efficient and easy-to-use device for producing feed for livestock and poult..

Product code: WIR-1000

5,065.22€

Availability: In stock

WIR-1000 Feed Mixer is a compact and efficient device designed for preparing feed mixtures with a mo..

Product code: MP-1500

3,115.94€

Availability: In stock

MP-1500 Feed Mixer is a well-designed device intended for preparing feed mixes with a moisture con..

Product code: MP-2000

3,579.71€

Availability: In stock

MP-2000 Feed Mixer is a modern and efficient device designed for preparing feed mixtures with moistu..

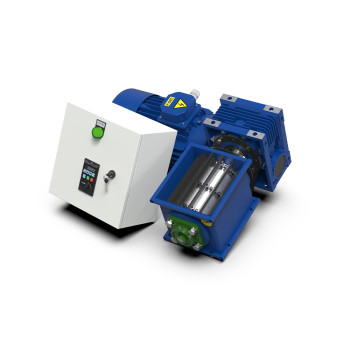

Product code: WIR-2000P

8,026.57€

Availability: In stock

WIR-2000 Feed Mixer with Feeder is a well-designed horizontal device created for preparing loose, mo..

Product code: MP-3000

4,492.75€

Availability: In stock

MP-3000 Feed Mixer – A Professional Solution for Large-Scale Feed Production The MP-3000 mixer is a..

Product code: MP-4000

4,746.38€

Availability: In stock

MP-4000 Feed Mixer – Performance and precision for large farms The MP-4000 mixer is a reliable devi..

Product code: WIR-4000

13,823.67€

Availability: In stock

The WIR-4000 horizontal feed mixer is an efficient and versatile device for preparing high-quality f..

Product code: MP-5000

5,050.72€

Availability: In stock

MP-5000 Feed Mixer – An Efficient Solution for Large Farms The MP-5000 mixer is a modern and robust..

Product code: MP

1,128.02€

Availability: In stock

The feeder for MP mixers is a modern device designed for the automatic transport of bulk materials t..

Product tags

Feed Mixers

Feed mixers are among the fundamental devices used in production facilities related to animal nutrition as well as on farms. The main task of these machines is to thoroughly blend and combine various feed components such as grains and meals, as well as protein ingredients or mineral additives. Modern feed mixers are suitable for both small farms and large industrial plants or production installations and are available in our offer.

When is it worth investing in a feed mixer?

Feed mixers are usually used for preparing high-quality blends for various species of farm animals. These devices are also effective as grain mixers. With their help, it is possible to efficiently combine different raw material fractions into a uniform feed product. As a result, a blend is created with the correct proportions of each ingredient and product consistency is maintained.

Well-chosen feed mixers are used in various areas of agriculture and processing. These machines influence the optimization of the nutritional process and the improvement of work organization within the plant.

It is worth investing in a feed mixer, among others, for:

- farms with pig, cattle, or poultry breeding, where high feed quality and adherence to nutritional standards are essential,

- small and medium-sized farms, where a user-friendly, compact feed mixer that doesn't take up much space is especially effective,

- breeding facilities and large farms in need of efficient feed mixers for preparing large feed batches in the shortest possible time,

- grain warehouses and feed preparation points – devices ensure precise blending of various ingredients according to order and needs,

- feed production plants as an element of the technological line,

- organic farms for precise combining of the highest quality ingredients.

You can choose from models of various sizes. These include a compact feed mixer as well as industrial feed mixers. They can function as standalone devices or as part of an entire technological line.

What feed mixers will you find in the TechnoMaszBud offer?

We offer horizontal and vertical feed mixers. This allows you to match devices to various needs and production scales.

Horizontal feed mixers

Horizontal feed mixers provide efficient mixing of large quantities of raw material, especially on farms as well as in facilities with increased feed demand. Our assortment includes, among others:

- horizontal feed mixer 1000 kg – suitable for medium-sized farms and feed mixing points,

- horizontal feed mixer 2000 kg – suitable for intensive work and for preparing large batches of material,

- horizontal grain mixer – a device for mixing grains, meals, and various feed additives,

- horizontal feed mixers for continuous operation – models adapted for use in production plants, including technological lines.

Horizontal feed mixers guarantee a short working cycle while maintaining high uniformity of the final blend.

Vertical feed mixers

Vertical feed mixers are versatile machines that take up less space than horizontal models. They are often chosen as compact feed mixers for smaller or medium-sized farms. Our offer includes devices such as:

- vertical feed mixer 1000 kg – suitable for daily feed production,

- compact vertical feed mixer 300 kg – perfect for small farms,

- vertical grain mixer – effectively combines various grains with feed components,

- high-capacity feed mixers – suitable for farms with high feed demand.

Each compact feed mixer, as well as larger mixer models, ensures thorough mixing of all ingredients while maintaining ease of operation and low running costs.

Our offer also includes a conveyor for feed mixers enabling automatic transportation of bulk materials to the pellet mill.

What makes TechnoMaszBud feed mixers stand out?

Feed and grain mixers available in the TechnoMaszBud offer are top-quality devices, designed for practical use as well as safe operation and optimal performance. Each offered model is distinguished by:

- even mixing of different types of ingredients,

- the ability to function as both a feed mixer and a grain mixer,

- the option to adapt to the intensity of use,

- compliance with all necessary safety regulations,

- simple, intuitive operation and straightforward maintenance rules.

Each feed mixer from TechnoMaszBud also comes with a warranty. The purchaser also receives service support and professional advice in choosing the right device as well as other products. For this purpose, simply contact us. We invite you to take a detailed look at our offer of feed and grain mixers. We will be happy to answer all your questions and help you make a choice.

Frequently Asked Questions – Feed Mixers

What is the difference between horizontal and vertical feed mixers?

Horizontal feed mixers are characterized by higher efficiency, especially when mixing large batches of material. Vertical mixers , on the other hand, take up less space and work well as compact devices.

What is a feed mixer used for?

A feed mixer is a device that allows for thorough and even combining of various feed ingredients. The result is a uniform mixture that stands out for its high quality and ensures consistent animal nutrition.

How do I choose the best feed mixer?

For smaller farms, a compact feed mixer is ideal. Here, small dimensions, simplicity of operation and effective mixing are crucial. For larger production facilities, it is worth choosing a large model with increased efficiency, which can operate in continuous mode.

Can a feed mixer be used as a grain mixer?

Each feed mixer can also serve as a grain mixer and combine different types of grains as well as additives.