Product code: CR-60

719.81€

Availability: In stock

The CR-60 Branch Shredder is a solid and reliable device designed for gardeners, farmers, and privat..

Product code: CR-80

835.75€

Availability: In stock

The CR-80 Garden Wood Chipper is an efficient and reliable device designed for the effective managem..

Product code: CR-500

4,137.68€

Availability: In stock

CR-500 wood chipper with an electric motor is a professional branch chipper as well as for slats, bo..

Product code: CR-500 SP

4,391.30€

Availability: In stock

CR–500 chipper is a robust and efficient machine designed to process branches, boards, offcuts, la..

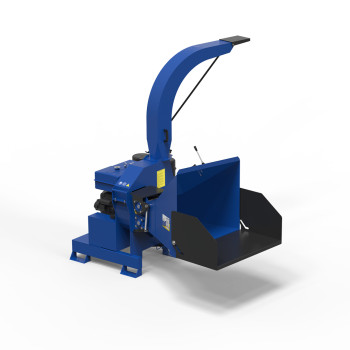

Product code: CR-500 WOM

2,886.47€

Availability: In stock

CR-500 Disc Chipper with PTO Drive is a robust machine designed for efficient processing of wood w..

Product code: CR-700

10,582.13€

Availability: In stock

CR-700 branch chipper with electric motor is a professional and efficient disc-type machine design..

Product code: CR-700_SP

9,992.75€

Availability: In stock

CR-700 branch chipper with a combustion engine is a professional, high-performance disc-type machi..

Product code: CR-700_WOM

6,615.94€

Availability: In stock

CR-700 PTO-driven wood chipper is a robust machine designed for efficient processing of wood waste..

Product code: ZMD

32,219.81€

Availability: In stock

The ZMD wood grinding set is a professional, fully automated technological system designed by Te..

Product code: AK-800

15,094.20€

Availability: In stock

AK-800 disc chipper with 4 knives is a professional wood chipper designed for efficient processing o..

Product code: ZUBR

15,410.63€

Availability: In stock

ŻUBR is an industrial drum shredder designed for shredding wood waste, branches, and offcuts, as w..

Product code: ŻUBR-30

19,526.57€

Availability: In stock

ŻUBR-30 wood shredder with feeding conveyor is a modern and efficient machine from TechnoMaszBud, de..

Product code: ZUBR-55

25,705.31€

Availability: In stock

ŻUBR-55 drum shredder is a modern industrial machine by TechnoMaszBud, designed for efficient grindi..

Product code: ŻUBR-75

27,531.40€

Availability: In stock

ŻUBR-75 sawdust wood shredder – an efficient and robust industrial machine by TechnoMaszBud, designe..

Wood Chippers / Wood Shredders

Wood chipper (also known as a branch shredder) is an industrial machine designed for the mechanical shredding of branches, boards, wood scraps, and other wooden waste into smaller fractions, such as wood chips or sawdust. It is commonly used in the production of pellets, briquettes, and pellet fuel.

We offer modern, technologically advanced wood chippers that allow efficient wood waste management in places such as:

- sawmills and woodworking plants,

- biofuel production companies,

- agricultural and household farms,

- gardening and municipal companies.

In our catalogue, you can find models with various power sources: electric wood chippers, petrol branch shredders, and also PTO-driven shredders.

Our devices are suitable for both domestic and commercial use. They easily handle tree branches up to 100 mm in diameter, boards, trims, edgings, and other wood waste, shredding them into small fractions of various lengths (depending on the thickness and hardness of the input material).

Selected models are equipped with additional conveniences, e.g., the Wood Shredder / Chipper AK-800 is fitted with a conveyor that facilitates material spreading and automates the packing process.

We offer machines that can be used successfully in various conditions. For private use, the compact CR-500 Electric Chipper will be perfect. For facilities with greater needs, an ideal solution will be e.g. the ŻUBR-55 Sawdust Wood Shredder with a capacity of up to 1500 kg/h.

Advantages of our wood shredding machines

Wood shredding machines available in our offer significantly reduce the cost, time, and effort required for the disposal or processing of wood waste. They stand out due to the following advantages:

- Versatility – they can be used to shred branches with a maximum diameter of 100 mm, as well as boards, trims, edgings, furniture panels, and other wood waste;

- High efficiency – the devices can process up to 15 m³/h of material, enabling efficient, continuous operation even with large amounts of material;

- Solid construction – industrial materials ensure high durability and resistance to intensive use; precision steel knives (9XC) are adapted to work in difficult conditions;

- Roll speed controller – allows adjustment of the feed rate and material fraction size;

- Large loading containers – enabling the shredding of larger units without the need for initial cutting;

- Easy operation and maintenance – the design makes cleaning easier, and the possibility to replace knives and other parts minimizes technical downtime;

- Operating safety – the user inserts material into a dedicated container, so there is no contact with the blades; the machines have a number of additional safeguards and covers.

Wood chippers work perfectly with other wood processing machines, including hammer mills and dryers, as well as pellet mills and granulators and other elements of pellet or briquette production lines. Our catalogue also features a complete wood grinding set.

Professional and efficient wood grinding into sawdust at your facility

We encourage you to check out our full range of wood chippers and branch shredders. The catalogue products come with detailed descriptions and illustrations, making it much easier to choose the right model. If needed, our experts will be happy to help you find a device that meets all your expectations and select other necessary equipment.

We invite you to a test of the selected machine on your own material at our facility!

Need more information? Call us at +48 22 266 28 33 or fill in the contact form. Discover how easily you can streamline the wood processing process in your home, farm, or business!