Aerodynamic dryer for sawdust SA-400

- Product Code: SA-400

Description

The Aerodynamic Sawdust Dryer SA-400 is a modern device for removing moisture from fine plant-based materials, such as sawdust, wood chips, straw, and grain waste. It is used during the preparation of raw material for pelletizing, fuel production, or further processing.

The aerodynamic sawdust dryer utilizes a proven operating principle: material is dried in a pipeline system, in which a stream of hot air flows. Under the influence of a controlled temperature, moisture from the surface of the raw material evaporates, while internal moisture migrates to the surface—this process ensures safe dewatering. The heat source is a firebox or pellet burner installed in a connected brick furnace (Burner is not included in the kit and must be ordered separately). The device works perfectly with pellet production lines and other processing systems.

When combined with a pellet production line, it provides a complete set for pellet producers.

It is possible to test this machine on your raw material at our warehouse!

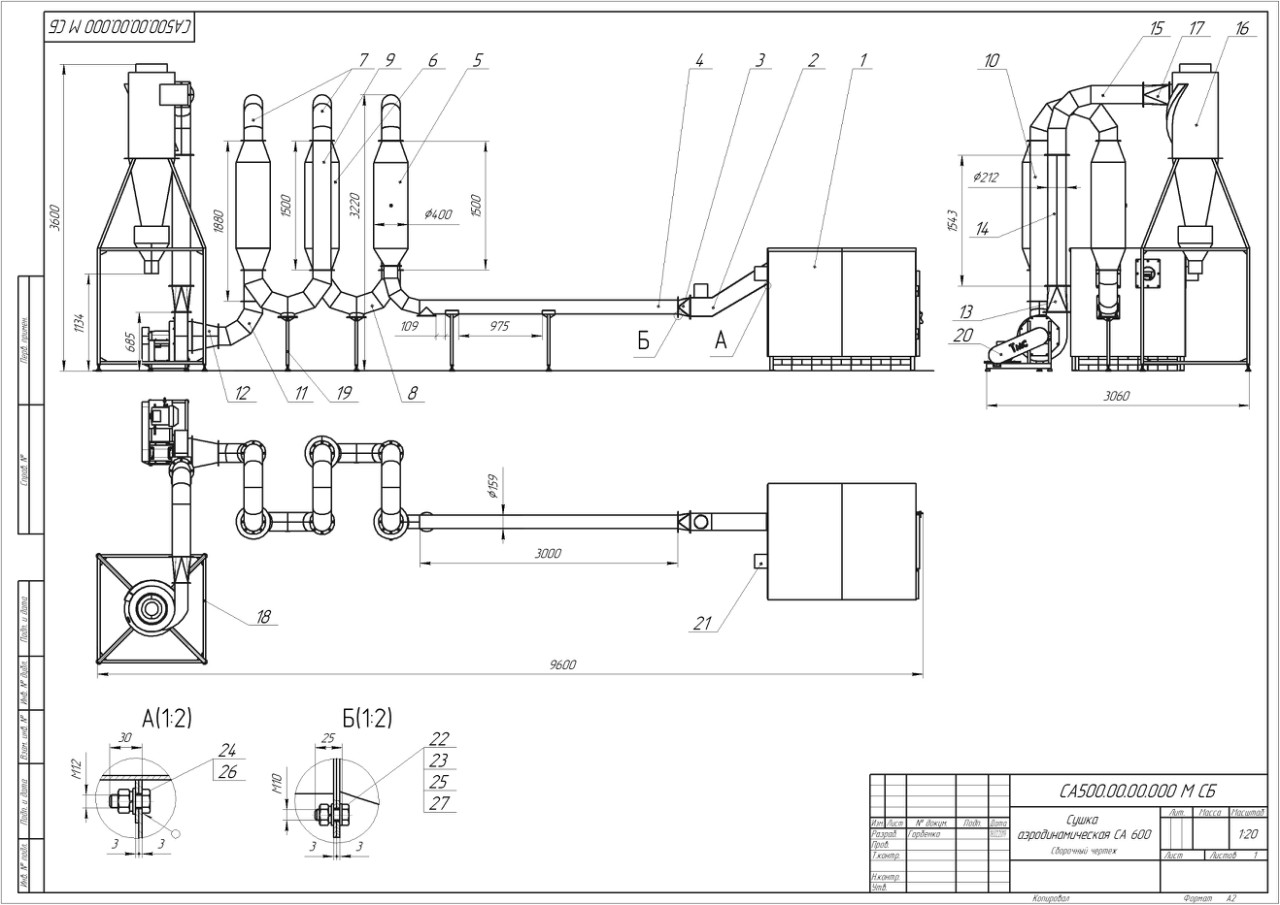

Set Contents

- Furnace (brick-made from 350 chamotte bricks)

- Calibrator (sieve)

- Pipeline system

- Anti-dust centrifugal fan

- Cyclone

- Control panel

Bricks for the furnace are not included in the set!

Video: LDG-3000 KOMBI line with SA-400 dryer – pellet production at customer site:

Advantages of the SA-400 Sawdust Dryer

- Versatility – enables drying of various plant-based materials such as sawdust (from conifer and deciduous trees), chips, straw, and grain waste.

- High efficiency – drying of up to 400 kg/h, covering the needs of most pellet production plants.

- Precise drying – quick and even reduction of water content in fine-fraction materials (from 60% down to 6-12%), which significantly shortens the time to prepare the raw material for subsequent processing stages.

- Advanced dual-chamber system– the construction solutionreduces the risk of material ignitionby monitoring temperature and ensuring proper air circulation.

- Easy operation – after calibration, the process is partially automated: the control panel and safety sensors provide precise control over the drying process.

- Economical energy consumption – the dryer is characterized by low energy use thanks to its connection with the furnace, reducing operational costs.

Bonus: digital laser thermometer and grease gun for lubrication included

Our aerodynamic dryers are delivered disassembled, which allows for easier transport and optimal use of space. Assembly of the dryer is a key process. We recommend consulting with our customer service specialist. Professional technical support will help solve any problems and ensure proper assembly of the dryer, affecting its efficiency and longevity.

Application of the SA-400 Pipeline Sawdust Dryer

The aerodynamic sawdust dryer SA-400 is a good choice wherever quick and efficient drying of plant waste is needed. The dryer is widely used in the wood and energy sectors, as well as in agriculture and pellet manufacturing companies.

The sawdust dryer is used to dry the following raw materials:

- deciduous and coniferous sawdust;

- chips;

- straw;

- grain waste.

Our equipment enables the production of fuel pellets with a density of 1–1.3 g/cm3, offering high combustion efficiency and heat output. The aerodynamic sawdust dryer produces environmentally safe products from wood industry waste.

The sawdust dryer processes raw materials up to 7 mm in size.

Fresh wood sawdust with 40–60% moisture and below is dried and prepared for pelletizing after a single pass through the dryer.

Operating stages of the sawdust dryer:

- The raw material is poured into the calibrator above the feed tank.

- At the same time, hot air—often called a “drying agent”—is blown into the pipeline.

- Together with the drying agent, the raw material is transported through the pipeline.

- Under the influence of high temperature, moisture evaporates from the surface of the raw material and internal moisture moves towards the surface.

- This process and the properly selected temperature prevent particle ignition.

Video: Pellet production from wood chips | 25 kW Line + Dryer

SA-400 Sawdust Dryer Technical Specifications:

- Capacity up to 400 kg/h.

- Length 9600 mm x Height 3600 mm x Width 3060 mm. Weight: 900 kg.

- Complete line with dryer: Length 13,000 mm x Width 5500 mm x Height 3600 mm. Weight: 1900 kg.

The product is delivered disassembled and must be assembled.

Video: How it works | Efficiency test. LDG-3000 KOMBI Pellet Production Line with dryer.

Video: Pellet production line | How it works, main components

Need more information about this device?

Contact us — we will advise you on the best solution for you!

Contact us