AF-8B automatic weighing and packaging machine

- Product Code: AF-8B

Description

Automatic Weighing & Packaging Machine AF-8B is a modern packaging line designed for fast and precise packaging of bulk materials using the weighing method. The high efficiency of the device (up to 480 packages per hour) significantly increases work efficiency in industrial plants, e.g. in the chemical industry, fertilizer or pellet industries. Thanks to the use of electronic control systems, the device is not prone to human error—ensuring repeatability of the process and saving raw materials.

The entire packaging cycle is performed automatically – from dosing the material, through forming and sealing the packaging, up to marking. The weighing range from 2 to 50 kg allows flexible adaptation to current production needs.

It is possible to test this machine with your raw material in our warehouse!

Main advantages of the AF-8B Weighing & Packaging Machine:

- High production efficiency – up to 480 packages/h with low power consumption (3.5 kW)

- Precise weight dosing – accuracy and control of dosing in the 2–50 kg range

- Full process automation – integrated system for weighing, forming, sealing, and marking

- Wide range of applications – ideal for packing pellets, salt, fertilizers, sand, gravel, and other bulk materials

- Quality control system – modern electronic control ensures stability and repeatability of parameters

- Packaging flexibility – supports plastic bags in various formats up to 1100 mm wide

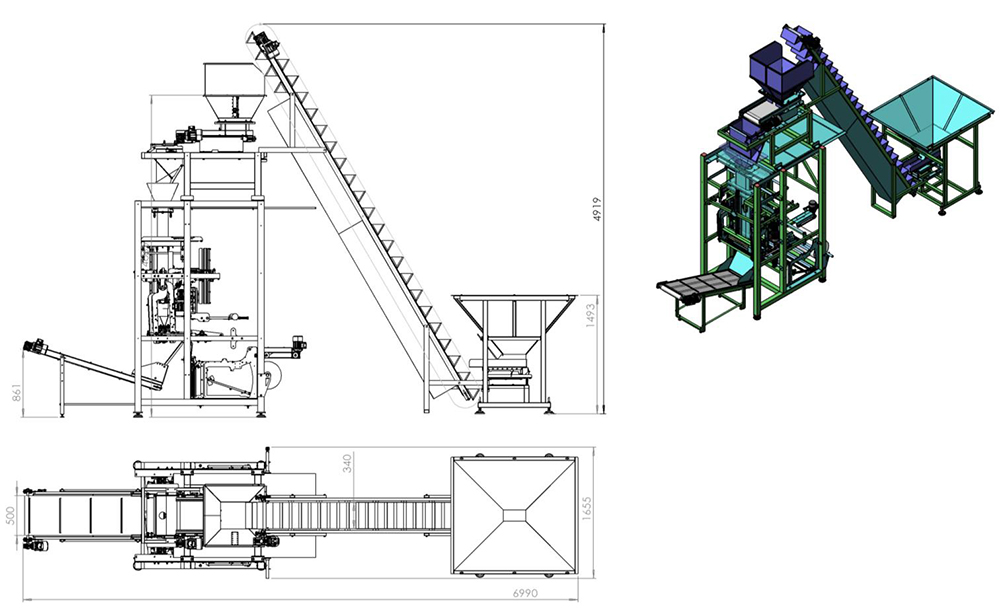

Technical drawing:

Design and operation

The packaging and dosing complex consists of a dispenser with a belt (vibrating) feeder and a packaging machine, which work as a unit and are controlled from a single control panel.

Belt (vibrating) weighing dispenser is equipped with one or two streams (weighing hoppers) and is controlled by a Libra controller. By default, the controller has 15 operating modes programmed for various portion weights and product types.

Packing machine is an independent, automatic mechanism with mechanical and pneumatic drives, controlled by a Mikra controller (with the option to install a touch panel). Its main task is to form packages from roll material. The machine allows you to:

- feed the film with a belt drive,

- form a "pillow" shaped package,

- using an additional folding module – create packages in the form of "stand-up pouches".

As an extra option, it is possible to install a handle forming module (3 holes), a thermal transfer printer for labeling the packaging, and protective covers.

New design solutions

Compared to the previous version AF-6, the AF-8 model received a completely new design that facilitates operation and service. Thanks to the new film sealing section, it is no longer necessary to thread material through the feeding and forming system each time. The sealing unit, based on impulse heating, works with a wider range of polymer films.

Materials and components

All elements in contact with the product are made of food grade 304 stainless steel. The AF-8-V machine is equipped with drives and components from renowned global manufacturers: STM, CAMOZZI, Libra, Mikra, Zemic, INVT, HYUNDAI.

Video: Automatic Weighing & Packaging Machine AF-8B | Pellet Packing

Operation description

The product to be packed is fed to the weighing dispenser’s loading tank via a loading conveyor or otherwise—depending on production requirements. From the tank, the product is transferred linearly by a belt (vibrating) feeder into the weighing hopper(s). When the set weight is reached, as defined in the "Libra" controller, the hopper(s) open and the weighed portion is discharged into the funnel of the forming unit (tube with collar).

The packing machine, pulling the film according to parameters set in the "Mikra" controller, forms a "pillow" shaped package (using the collar), sealing the longitudinal rear seam and the bottom seam.

The product pours from the weighing hopper(s), passes through the tube of the forming unit, and fills the prepared package. Then an impulse seal of the final seam of the filled bag is performed, along with the bottom seam seal of the next package, as well as cutting off the finished package.

The finished, filled package falls onto a receiving conveyor or another device—depending on production requirements.

Application

The AF-8B Automatic Weighing & Packaging Machine is designed for use in sectors where reliable and economical packaging of bulk materials is required. AF-8B is suitable for the pellet industry (for packing biomass in 2–50 kg bags), the fertilizer industry (for packing mineral or organic fertilizers), construction (e.g. for gravel or sand), as well as in the chemical and technical industries.

Technical parameters:

- Power supply: 380 - 400 V / 50 Hz

- Installed power: 4 kW

- Pneumatic supply: 6 atm / 500 l/min (compressor required)

- Dimensions (H × W × D, max): 4600 × 1800 × 2100 mm

- Weight (max): 1200 kg

- Packaging material thickness: 40–130 µm

- Packaging material: any

- Package dimensions (H × W): height 200–800 mm, width 200–500 mm

- Dosing range: 2000–50000 g

- Output (kinetic): 500 packages/h

- Sealing type: impulse

- Package forming: tube with collar

- Film operation: by photomarker / by length

- Fault monitoring system: yes

- Control panel of packaging machine: button type with light signaling

Need more information about this device?

Contact us – we will recommend the best solution for you!

Contact us