Bagging line LPW-1

- Product Code: LPW-1

Description

LPW-1 Packing Line is a complete and functional technological solution designed for precise dosing and packing of lightweight bulk materials into open bags, followed by their sealing. The installation stands out for its compact design and mobility, making it ideal for production halls with limited space.

Low energy consumption is achieved by using solutions based mainly on mechanical operating principles, which results in high reliability and low operating costs. The LPW-1 line is used for packing grains, seeds, feeds, granulated products, and other bulk materials.

It is possible to test this machine with your raw material in our warehouse!

Line Composition

1. ZK-1 Buffer Hopper

The hopper is designed for receiving, storing and preliminary preparation of the raw material before the dosing process. It is equipped with two vibrating motors to ensure even material feeding and a calibration screen to separate contaminants and caked fractions.

Capacity: 8.8 m³

Basic parameters:

- Lower conical part capacity: 2.2 m³

- Upper section capacity: 6.6 m³

- Total capacity: 8.8 m³

- Wall thickness: 2 mm

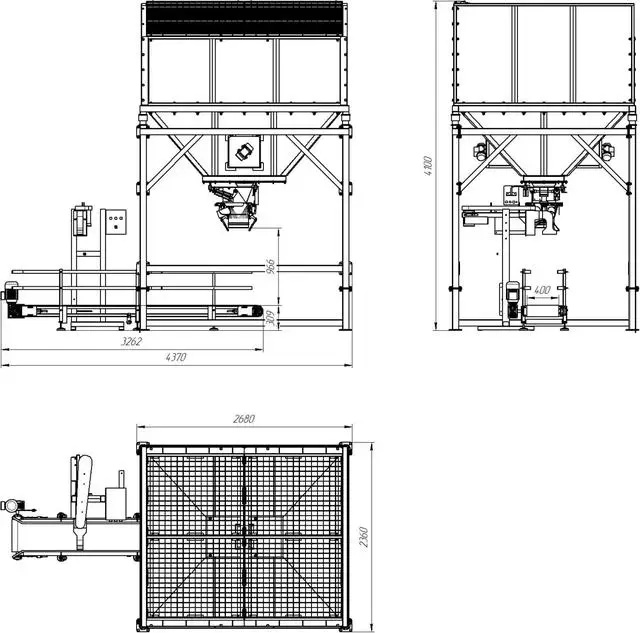

- Dimensions (L x W x H): 2680 x 2360 x 3600 mm

- Weight: 1120 kg

2. Norma-S Weighing Dispenser

Responsible for accurate weighing and filling of open bags with bulk materials, from fine-grained to granulated. It ensures dosing stability, high repeatability, and convenient operation in continuous mode.

Functional advantages:

- Automatic counting of filled bags

- Stable output during intensive operation

- Modular design allowing for extension

- Easy access to service and adjustment elements

- Capability of rigid connection to the loading hopper

- Integrated dust removal system

- Data transfer to registration system

Technical parameters:

- Output: up to 500 doses/h

- Dosing range: 5-50 kg

- Dosing accuracy:

- 5-15 kg - ≤ 0.37%

- 15-50 kg - ≤ 0.1%

- Minimum bag width: 455 mm (250 mm*)

- Height with 50 kg bag suspended: 1550 mm

- Device weight: 70 kg

- Air consumption (4 atm): up to 1.0 m³/h

- Power consumption: up to 60 W (230 V)

* When using SM spout.

3. Belt Conveyor with LZK-500 Bag Sewing Module

Responsible for the final stage of the packing process, ensuring continuous and smooth transport of filled bags and precise positioning before the sewing unit.

Main features:

- Smooth transfer of filled bags

- Precise positioning before sewing

- Conveying closed bags to the receiving zone

Technical data:

- Output: up to 500 bags/h

- Belt speed: 0.12 m/s

- Standard conveyor length: 3 m

- Structure weight: up to 300 kg

- Installed power: up to 1.5 kW (supply 380-400 V)

Technical drawing:

Optional extras:

- Adjustment of sewing head height

- Production of conveyor in non-standard length

- Adjustment of conveyor height for integration with other machines

The LPW-1 packing line combines simple construction, reliability, and low operating costs, making it an effective solution for small and medium-sized production plants.

Need more information about this device?

Contact us—we will advise you on the best solution for your needs!

Contact us