Briquette production line LDB-350 DUO with dryer SA-800

- Product Code: LDB-350Duo+SA-800

Description

LDB-350 DUO briquette production line with SA-800 dryer is a complete production line for processing biomass with moisture content up to 60% into high-energy, high-quality Nestro type fuel briquettes. The LDB-350 DUO combines the functions of drying, separation, conveying and compacting raw materials.

The line's output reaches up to 700 kg/h.

LDB-350 is used to convert organic waste into valuable and eco-friendly solid fuel in the form of compact blocks.

It is possible to test this machine on your raw material at our warehouse!

Operation of the technological line

The briquette production process begins by loading the raw material into the KPS-600 calibrator, which removes contaminants.

The cleaned raw material goes to the SA-800 drying system, where air heated by a chamotte furnace warms the biomass in an aerodynamic system.

The next stage is feeding the dried material to two BT-350 briquetting presses. The PS-200 DUO conveyor handles the movement of the biomass.

Dust formed inside the installation during the entire production process is captured by the SO-2 extraction system. The collected dust is recirculated for reuse.

The entire briquette production process is operated from the control panels.

In the following step, the compact and dense briquette is extruded.

Main advantages of the LDB-350 DUO pellet production line with SA-800 dryer

- Capable of processing biomass with up to 60% moisture content

- High performance: 500–700 kg/h

- Efficient dryer with chamotte furnace

- Double briquette press and conveyor system

- Interchangeable forming sleeves allow for adjustment of briquette diameter and length

- Briquette type: Nestro (round, without a hole)

- Standard diameter: 50 mm (others upon request)

- Briquette length: adjustable (200–300 mm)

- Power supply: 380–400 V, 50–60 Hz

- Total power: 66 kW

- Extraction system reduces dust emissions and increases efficiency

- Operation via control panel with monitoring and safety features

- Warranty: 12 months

Advantages of briquettes compared with raw biomass

- Higher calorific value (10–20% more energy)

- Lower fuel consumption for the same amount of energy

- Lower smoke and dust emissions

- Reduced amount of ash (2–3 times less)

- Better logistics: easier transport and storage

- Stable quality and fuel form

- Renewable raw material, compliant with the principles of sustainable development

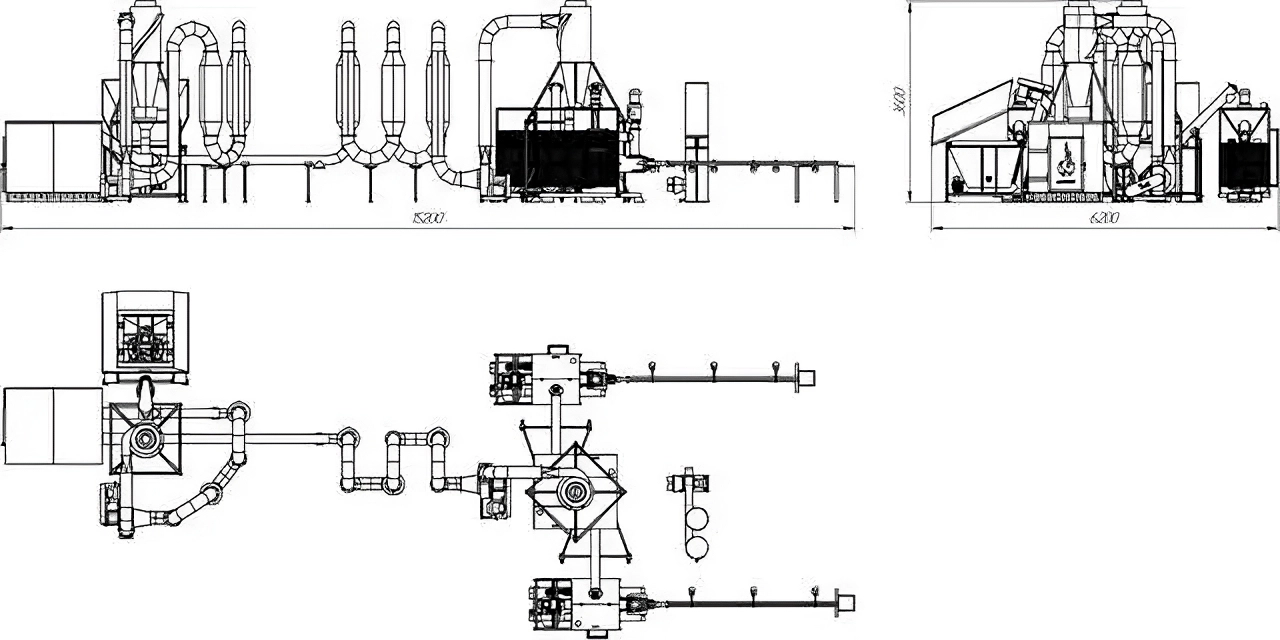

Technical drawing:

Application

LDB-350 DUO briquette production line with SA-800 drying system is an excellent solution for all types of processing plants, industrial facilities, and farms handling large amounts of biomass.

The briquette production line enables the conversion of waste designated for disposal into eco-friendly, high-energy solid fuel.

Producing your own briquettes is both economically and environmentally beneficial.

The line consists of:

- Aerodynamic dryer SA-800 – 14.7 kW

- Briquette press BT-350 – 2 units of 23 kW each

- Screw conveyor PS-200 DUO – 3 kW

- Extraction system SO-2 – 1.5 kW

- Line control panel

Technical data

- Total motor power: 65.2 kW

- Capacity: 500–700 kg/h

- Briquette diameter: 50 mm

- Briquette type: round cylinder without holes

- Briquette length: any

- Dimensions (L×W×H): 18,000 × 5,000 × 2,300 mm

- Weight: 4,000 kg

Need more information about this device?

Contact us – we will advise you on the best solution for you!

Contact us