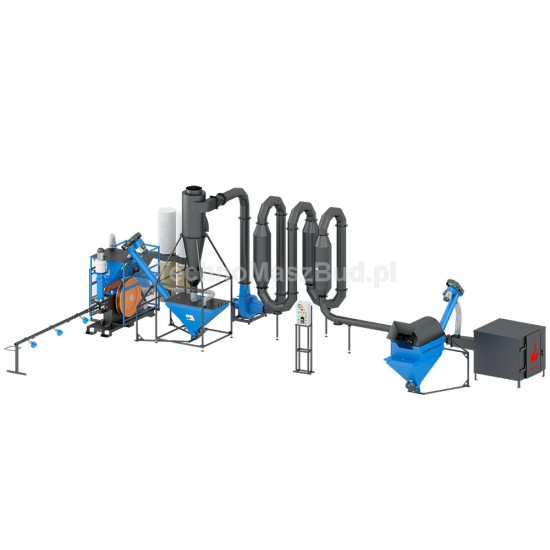

Briquette production line with dryer SA-400

- Product Code: bt-350+sa-400

Description

Complete Solution for Converting Biomass into Eco-Friendly Heating Fuel

BT-350 Briquette Production Line with SA-400 Dryer is a compact, efficient, and well-optimized technological installation designed to convert biomass into high-energy solid fuel.

The BT-350 line is designed for briquetting biomass with moisture content up to 60%.

The energy value of the final product from the BT-350 line is 3800–6000 kcal/kg. The use of aerodynamic drying technology and mechanical-piston pressing allows the BT-350 briquetting machine to achieve output of up to 350 kg/h with relatively low power consumption – about 30 kW.

You can test this machine with your own raw material in our warehouse!

Key Advantages of Briquetting Line with SA-400 Dryer

- High drying and briquetting output – up to 350 kg/h

- Consistent quality briquettes – burn evenly for 1.5–2 hours

- Energy efficiency – optimized energy use and no heaters in the process

- Eco-friendly fuel – high calorific value, low sulfur and ash emissions

- Compact design – suitable for facilities with limited space

- Easy operation – simple process control and fast staff training

- Processing various raw materials – sawdust, sunflower husks, straw, reed, grains

- Compliance with sustainable development principles

Technological Set Composition

- BT-350 Briquetting Machine – output up to 350 kg/h, briquette density up to 1.4 kg/cm²

- SA-400 Aerodynamic Dryer – reduces moisture content to 12%

- PS-200 Screw Conveyor – ensures constant material flow

- Control system and working tank – fully integrated into the line

Binderless Briquetting Technology – Less Chemicals, More Energy

Our briquetting technology was specially developed for recycling waste generated during wood processing, grain or flax processing.

The high-pressure pressing process without binding agents used in the BT-350 biomass briquetting line utilizes the natural lignin contained in the raw materials, which under the influence of temperature and pressure acts as a natural binder.

Video: Briquetting of Sawdust/Straw | BT-350 Mechanical-Piston Briquetting Machine

Why is a mechanical-piston briquetting machine a perfect choice?

Biomass briquette production eliminates the need for waste storage by turning it into fuel with a calorific value similar to coal, but with dozens of times lower ash content!

Applications of the Briquette Production Line with SA-400 Dryer

The BT-350 solid fuel production line with the SA-400 dryer is a solution created for wood processing plants, sawmills, farms with constant access to biomass, companies specializing in biomass processing, agri-food processing plants, and energy enterprises.

The compact design and low operating costs of the BT-350 line with the A-400 dryer allow the conversion of production or agricultural waste into an eco-friendly and profitable heating product – biomass briquettes.

Technical Data

Total electric motor power: 27.5 kW

Output: up to 250–350 kg/h

Briquette diameter: 50 mm

Briquette type: round cylinder without holes

Briquette length: any

Weight: 2800 kg

Need more information about this device?

Contact us – we will advise you on the best solution!

Contact us