DVSV-S: semi-automatic weighing dispenser for free-flowing products | up to 1,000 portions/hour.

- Product Code: DVSV-S

Description

DVSV-S is a semi-automatic auger dispenser designed for precise weighing and portioning of a wide range of bulk products. The device uses natural gravitational drop, allowing for efficient and rapid filling of packaging without the need for complicated transport mechanisms.

This is a reliable device for dispensing bulk products, ideal for manufacturers seeking efficiency while maintaining high accuracy—even up to 1 g. The DVSV-S model can operate independently or be part of a larger packing line.

The dispenser is intended for portioning bulk products into containers, bags, and open-type boxes in doses from 0.2 kg to 10 kg.

You can test this machine with your own raw material in our warehouse!

Key advantages of DVSV-S:

- High weighing precision – the tensometric measurement system guarantees accuracy up to ±0.5%

- Universal application – for flour, sugar, pellets, granules, and other bulk materials

- Simple operation – intuitive control panel with quick settings adjustment

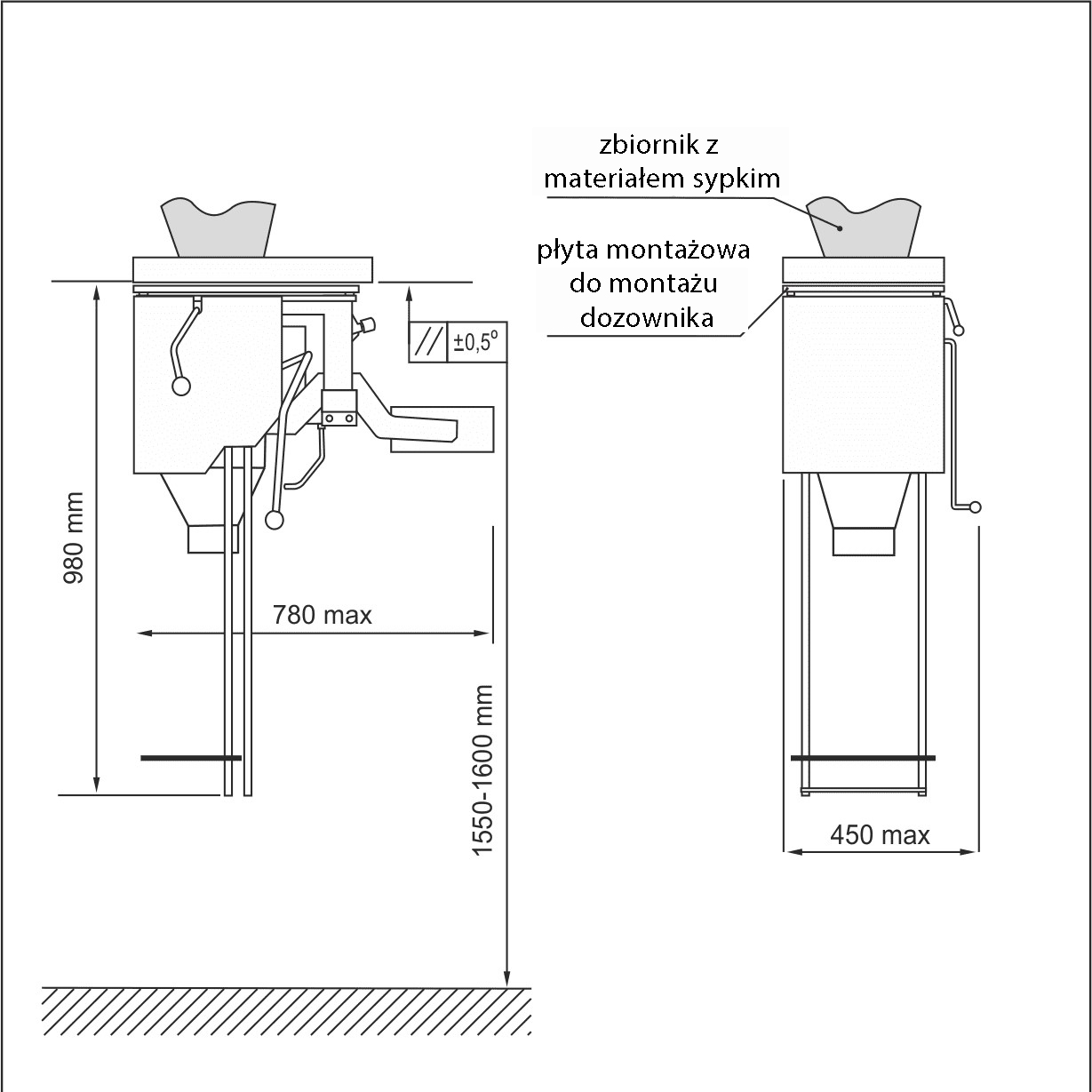

- Compact design – space-saving in the facility

- Easy cleaning and maintenance – access to wear parts without disassembly

Application

DVSV-S bulk material packaging dispenser is widely used in industry, especially where cleanliness and precision are essential. It can be used as a dispenser for packing flour and sugar, as well as for other raw materials with a bulk structure.

This auger dispenser fits perfectly into the needs of modern production plants, thanks to its compact design that makes it easy to place the machine within a production line.

Technical data:

Main product types: sugar, seeds, grain, fodder, coffee beans, salt, groats, mineral fertilizers, laundry powders, heating pellets, dry building mixtures, plastic granulates, and others.

Description of dispenser operation:

The dispenser works on the principle of cyclic portioning of doses of the specified weight into open-type packaging.

Dosage process steps:

- The operator places the bag, container, or box on the table.

- Opens the slide gate to start the dispensing process.

- Once the set weight is reached, the slide gate closes automatically and the dispensing process is complete.

Technical specifications:

- Minimum dose: 0.2 kg

- Maximum dose: 10 kg

- Accuracy (discretization): 0.005 kg

- Accuracy class: 0.1

- Capacity (for 1 kg portion): 1000 doses/h

- Capacity (for 10 kg portion): 700 doses/h

- Overall dimensions: 800 × 450 × 980 mm

- Weight: 71 kg

Need more information about this device?

Contact us – we will advise you on the best solution!

Contact us