Grain cleaning machine (separator) MC-500

- Product Code: mc-500

Description

MC-500 grain cleaning machine, also called a separator, is designed for the effective removal of impurities from seeds. The device is intended for use in both small and large farms.

The operator can individually adjust the fraction size and load various types of grain, such as rye, wheat, sunflower seeds, corn, legumes, or coffee beans.

You can test this machine on your material at our warehouse!

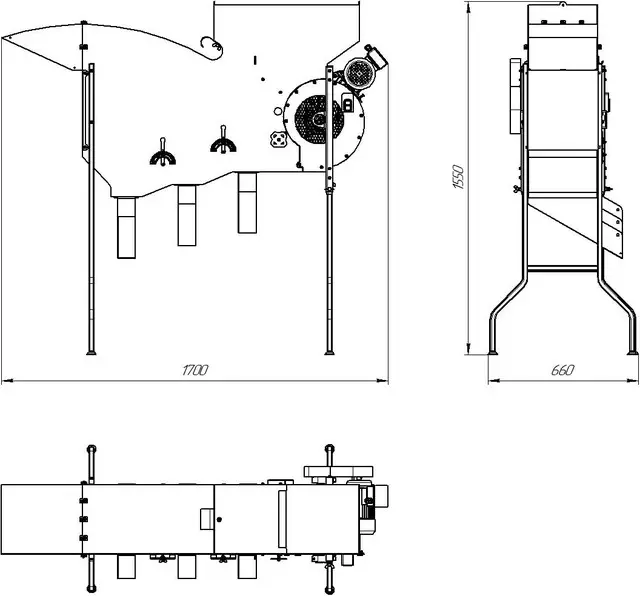

Technical drawing:

Principle of operation

The operating principle of the separator is based on feeding grain into the receiving hopper, where it spreads evenly and flows into the separation chamber under its own weight. Under an intensive airflow, heavy impurities and stones are separated first and directed to the first fraction. The cleaned grain moves to the next tray, while the remaining impurities and damaged kernels are carried by the air stream to the last tray. Light impurities and dust are removed through the air outlet.

Thanks to calibration and mass-based separation, the grain is prepared for sowing, which makes it possible to select the most fully developed kernels, ensuring a healthy embryo. This process increases grain uniformity, reduces the amount of seed material needed, and raises yield.

Pre-cleaning aims to remove dust and partially eliminate non-grain impurities, which speeds up preparing grain for further processing and temporary storage.

Video: MC-500 grain cleaning machine:

Applications of the MC-500 grain separator

The seed cleaning machine is used on farms engaged in the distribution of grains or other types of seeds. Seed separator will work well for both large industrial crops and small local agricultural operations.

The easy-to-use machine does not require special qualifications and can be successfully operated by one person.

Need more information about this device?

Contact us—we will recommend the best solution for you!

Contact us