Hammer mill MB-1000 + Hopper-feeder TYTAN-5

- Product Code: TYTAN-5 + MB-1000

Description

Hammer Mill MB-1000 is a professional and reliable machine for shredding chips, wood shavings, wood processing waste and other raw materials into a fine fraction intended for further production processes.

Hammer mill for wood chips MB-1000 together with the TYTAN-5 hopper / feeder create an efficient and reliable system for dosing and grinding biomass and bulk materials.

The robust construction of the devices, the high power of the motors, and the possibility of adjusting the degree of biomass fragmentation make the set: hammer mill for wood MB-100 + TYTAN-5 hopper-feeder a universal technological solution both for farms as well as companies engaged in the production of feed, pellets, or fuel.

You can test this machine on your own material in our warehouse!

Performance of the MB-1000 + TYTAN-5 device set

- Shredding wood and feedstock materials – up to 1000 kg/h*

- TYTAN-5 feeder capacity – 5 m³

*Performance depends on the type, fraction, and physical properties of the material.

Advantages of the MB-1000 + TYTAN-5 set

- High efficiency with low energy consumption;

- Versatility – processes grain, sawdust, wood chips, veneer, shavings, and other materials;

- Fraction adjustment – possibility to set the degree of material fragmentation;

- Simple and compact design – facilitates operation and maintenance;

- Durability and reliability – robust construction and hardened components;

- Low operating costs – quick replacement of screens and hammers;

- Operating safety – the set is equipped with a control panel with a frequency converter.

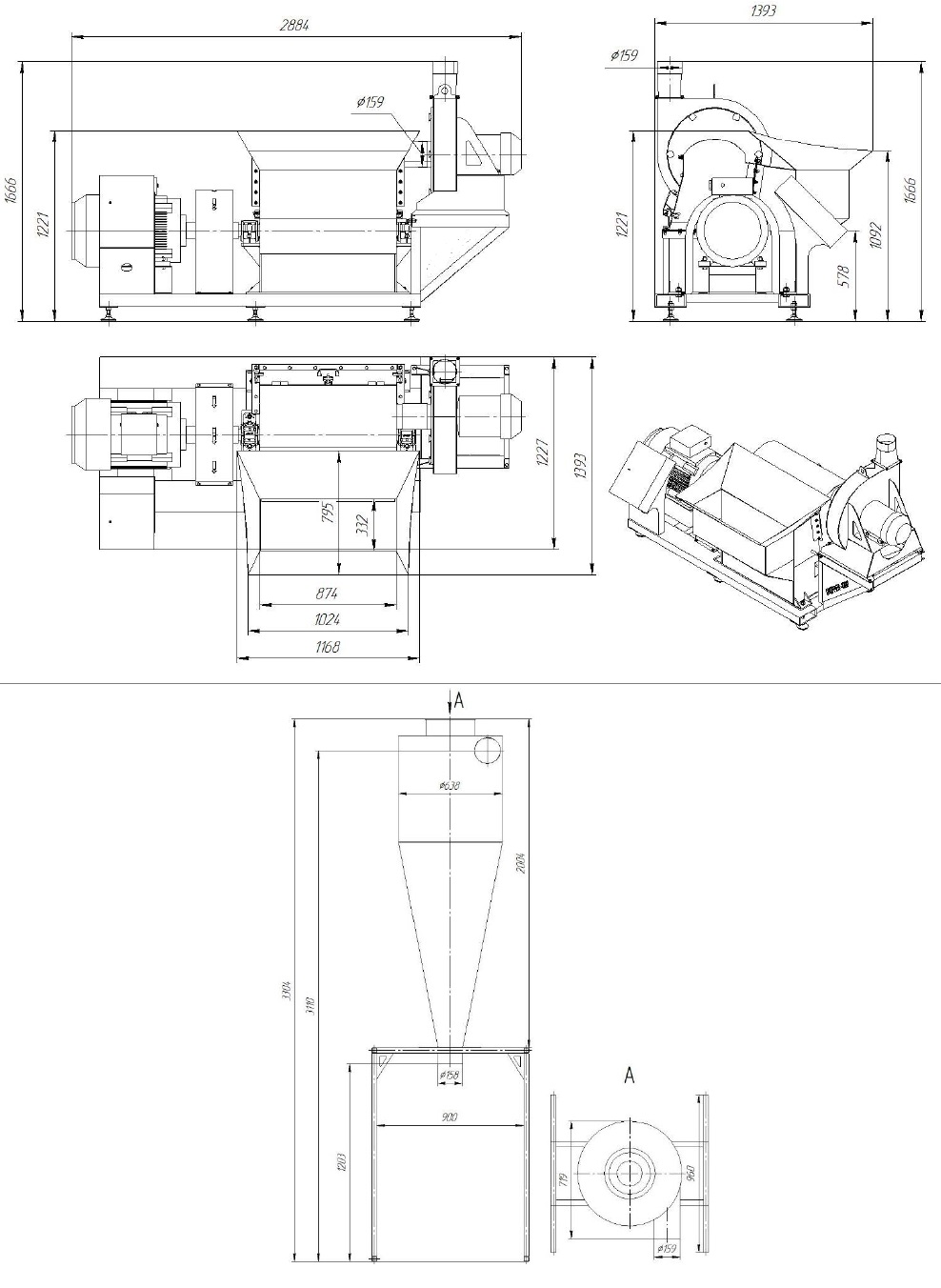

Technical drawing:

Application of MB-1000 hammer mill + TYTAN-5 feeder/hopper

The set of devices: MB-1000 hammer mill for wood chips + TYTAN-5 feeder/hopper is used in agricultural holdings, feed mills, and companies engaged in wood processing or biofuel pressing, such as pellet or briquette from wood biomass. The MB-100 set with TYTAN-5 feeder enables efficient and smooth shredding of wood chips, shavings, sawdust, veneer, or cereal waste into a fine fraction of size set by the mill operator of the MB-1000 shredding hammer mill.

Thanks to the TYTAN-5 feeder, the process of feeding material into the mill is smooth and automated, which significantly increases work efficiency. The shredded material can then be directed to a cyclone, feed mixers or granulation lines.

The set is suitable wherever continuous material feeding, high efficiency, and reduction of pellet, feed or other forms of pelleted biomass production costs is crucial.

Video: TYTAN-5 Feeder-Hopper for biomass feeding

Video: Hammer Mill MB-1000 | For grinding carpentry waste, wood chips, grain

Output:

- up to 1000 kg/h

* Crusher output depends on the type and physical properties of the shredded material and the achieved fraction.

Technical data:

- Motors: 55 kW and 11 kW

- Dimensions (L×W×H): 2824 × 1393 × 1666 mm

- Weight: 1980 kg

- Loading opening dimensions: 870 × 332 mm

- Loading height: 1100 mm

- Number of hammers: 56 pcs.

Cyclone specifications:

- Weight: 70 kg

- Dimensions (L×W×H): 1058 × 1367 × 3302 mm

Electricity consumption:

- 66 kW

TYTAN-5 hopper parameters:

- Gear motor: 5.5 kW (380-400 V)

- Dimensions (L×W×H): 4600 × 1500 × 1800 mm

- Drive: chain

- Capacity: 5 m³

- Weight: 840 kg

- Set includes: control panel with frequency converter

Need more information about this device?

Contact us – we will recommend the best solution for you!

Contact us