Horizontal slotting machine DP-12

- Product Code: DP-12

Description

DP-12 Horizontal Slotting Machine is an efficient and precise device for metalworking, classified as a horizontal slotting machine. Designed for use in industrial plants and mechanical workshops, it can also serve as an alternative to smaller horizontal broaching machines, especially in processes such as keyway slotting, keyway broaching, and keyway cutting.

Our machine is designed for making keyways, splines, internal hexagons, and other non-standard shapes, such as slots with unusual profiles or recesses for press-fit components. Holes in steel, cast iron, and non-ferrous metal parts can be machined with high precision and repeatability, regardless of the complexity or hardness of the material.

Thanks to the use of a cam-driven slide system, the device ensures high repeatability and precision of operation. Smooth adjustment of operating parameters enables quick adaptation of the machine to the requirements of a specific part, which significantly increases production efficiency.

The body of the DP-12 slotting machine is made of steel, which guarantees stability during operation and vibration damping. Its compact design means the machine takes up little space and can be easily integrated with other workstations.

You can test this machine on your own material at our warehouse!

Main advantages of the DP-12 slotting machine:

- High machining precision – thanks to the stable body and precise cam mechanism

- Wide range of applications – ability to slot various internal shapes

- Adjustable worktable – full control over workpiece positioning

- Robust industrial construction – suitable for continuous operation

- Compact dimensions – easy integration with other machines

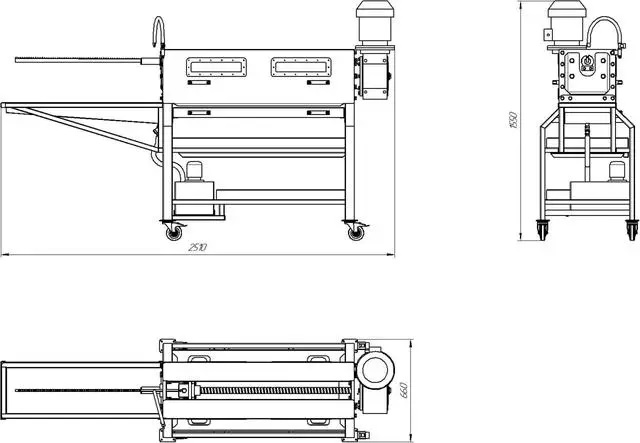

Technical drawing:

Applications

DP-12 horizontal slotting machine is an ideal choice for companies seeking a reliable and precise solution for internal slotting, especially when working on parts with complex geometries. With a slide working length of 1105 mm, a wide range of table adjustments, and the ability to set the working angle, the device allows flexible adaptation to various technological tasks.

The compact dimensions and the powerful 3 kW motor make it a practical and versatile tool for any manufacturing facility. Combined with other slotting and horizontal broaching machines, it can become a part of a comprehensive machine park for precise internal machining.

Main features:

- simple operation

- mobility and compact design

- high broaching efficiency

- high-quality HIWIN ball screws

- hardened and ground shaft guides

- reliable worm drive made in the EU

Standard equipment:

- broach of choice – 1 pc.

- broach holder – 1 pc.

- wedge for broach clamping – 1 pc.

- control panel – 1 pc.

- coolant feed system – 1 set

- wheels with d100 lock – 4 pcs.

- operation manual – 1 pc.

Technical data

- Maximum slot width: 12 mm

- Pulling force: 30 kN = 3 t

- Broaching speed: 1250 mm/min

- Return speed: 2500 mm/min

- Drive power: 3.0 kW

- Maximum workpiece diameter: 310 mm

- Maximum broach length: 1105 mm

- Dimensions (L×W×H): 2510 × 660 × 1550 mm

- Weight: 180 kg

Need more information about this device?

Contact us – we will advise the best solution for you!

Contact us