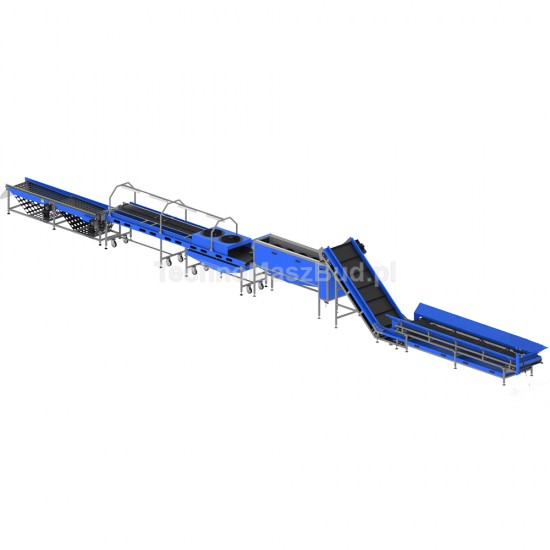

LDW-830 vegetable washing line with inspection table

- Product Code: LDW-830

Description

LDW-830 line equipped with an inspection table is a comprehensive system for automating the washing and inspection of vegetables. It is designed primarily for the food industry, where it plays a key role in preparing vegetables for further processing or packaging.

The LDW-830 line consists of 8 modules that perform a number of key operations, such as:

- loading– the vegetables are loaded onto arod conveyor with a feed hopper with a capacity of 2.5 m3. You can use a box pallet tipper (option) or a loader (not part of the set);

- transport– anL-shaped belt conveyoris used for this operation, which effectively and gently transfers the vegetables, ensuring appropriate throughput and careful handling;

- washing– the washing process takes place in a drum washer with a discharge conveyor, by rubbing the product against the drum walls. After washing, the products are transported by a conveyor to the next processing stage;

- brushing– root vegetables are washed in a tank with rotating brushes and water nozzles. High-pressure water removes dirt, and the rotating brushes ensure thorough washing. After washing, the vegetables are transferred to a discharge tray;

- drying fruit and vegetables– the dewatering process is performed by a machine with felt rollers, ensuring effective removal of moisture from the products;

- inspection– the vegetables are manually sorted on an inspection table. Damaged or contaminated items are removed.

The line is operated via a single control panel that enables control over all its elements. This panel allows powering individual components, adjusting the speeds of the infeed belts and the inspection table, as well as the brush speed. It is also equipped with a power indicator, frequency inverters, and an emergency stop button. Additionally, each element of the line is equipped with an emergency stop button.

Example line layout and dimensions.

Features and benefits of the LDW-830 vegetable washing line with inspection table:

- total capacity: up to 3,000 kg/h;

- overall dimensions are just 27 x 0.9 x 1.7 m;

- connection requirements: only a 14.2 kW electrical supply and up to 7 m3/h of water supplied at a pressure ≥ 3 atm;

- loading method: forklift, container tipper, manual loose loading, or other;

- feed hopper capacity: 2.5 m3;

- single load: 70–80% of the hopper volume;

- one panel to control all line elements (separate panels for each element – optional);

- easy installation – the line is easy to install and commission, allowing a quick start-up;

- expandability – the line can be extended with additional modules such as optical sorters and packaging machines.

Additional equipment:

- box pallet tipper;

- weight grading (individually adjustable, commonly used 40, 50, 55, 60 g);

- can be packed into bags, nets, sacks with a packing range of 5–30 kg;/li>

- the line elements (except the grader) can be fitted with 160 mm diameter wheels for convenient moving and maintenance.

Thanks to its advantages, the LDW-830 line is an optimal solution for production plants, food processing facilities, and fruit and vegetable wholesalers seeking efficient methods for washing and inspecting vegetables. The line enables increased throughput, improved product quality, hygienic working conditions, and reduced labor costs and waste.