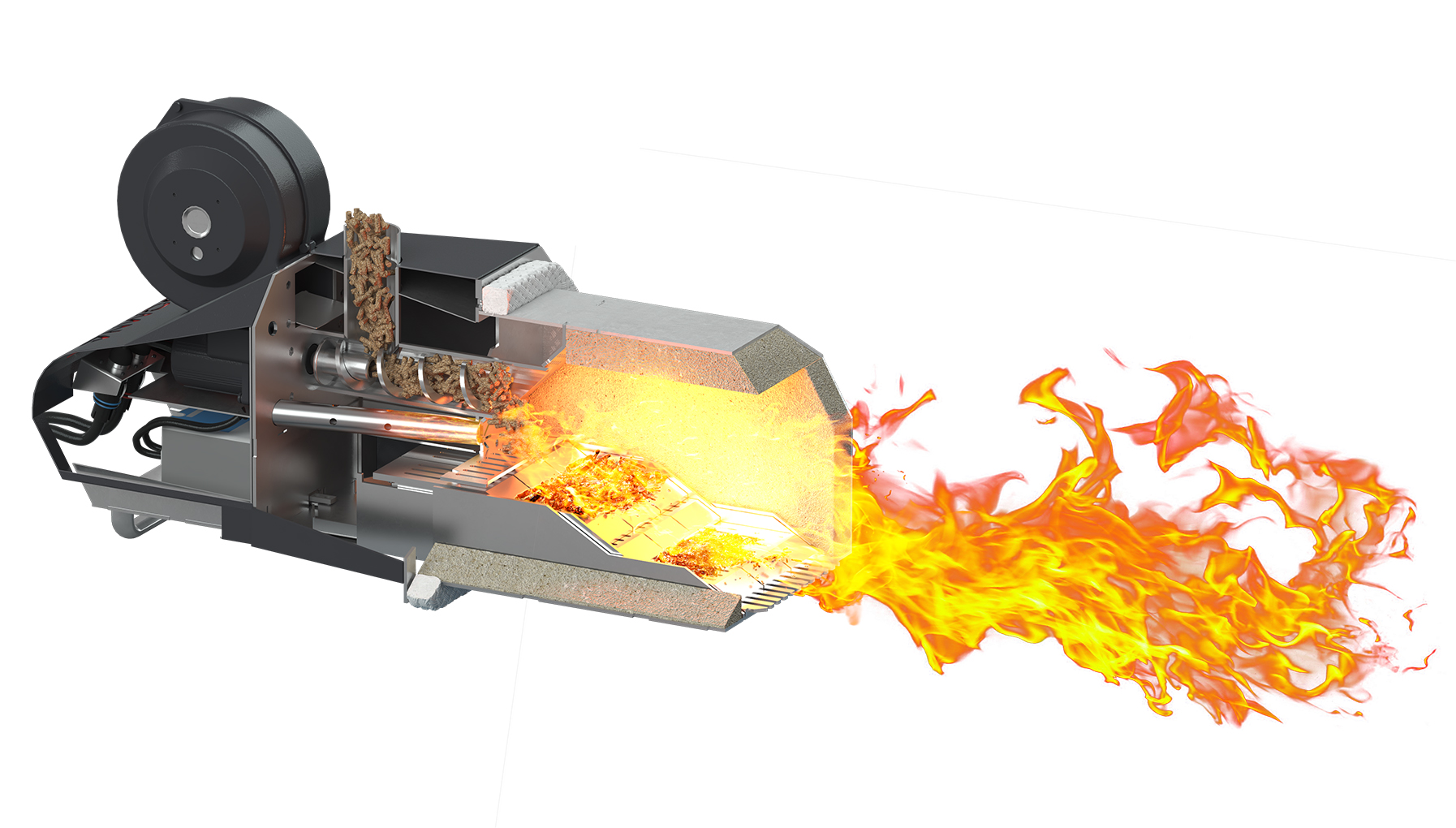

Pellet burner DOMNA MAX 350 kW

- Product Code: DOMNA-350

Description

The DOMNA MAX-350 pellet burner is the most powerful heating device in the DOMNA range, designed for large-scale industrial applications. Offering an impressive output of 350 kW, it is ideally suited for manufacturing plants, drying facilities, district heating plants, agricultural enterprises, and anywhere a stable and efficient heat source is required.

The device features a modern PLUM controller, automatic ignition, and an efficient self-cleaning system. As a result, operation is virtually maintenance-free, while maintaining very high efficiency – up to 98%.

It is possible to test this machine using your material at our warehouse!

Operating Principle

Pellet is delivered to the burner via a screw feeder and burned on a specially designed grate. The blower provides the right amount of air to ensure clean and efficient combustion. The generated heat goes to the heating boiler, which then transfers it to the system. The advanced PLUM system controls the process, supervising operating parameters, fuel feeding, and temperature.

The set includes:

- DOMNA MAX-350 burner

- Controller with a set of sensors

- Feeding screw Ø100 x 1800 mm

- Pipe Ø100 x 1200 mm

- User manual

- (Optional: rotary safety valve or vacuum system)

Main Advantages of the DOMNA MAX-350 Burner

- Ceramic combustion chamber in all burner models – guarantees complete and high-quality combustion thanks to the creation of a thermal core. The heat is not transferred to the burner chamber (thus avoiding damage), but remains inside the combustion chamber and acts as a specific catalyst for full fuel burnout. The resulting flame is cleaner, and there is less ash and slag, even with low-quality fuel.

- Cast iron grates – they do not burn out or deform at high temperatures, unlike stainless or regular steel grates. Cast iron grates perfectly retain the high temperatures generated by the ceramic combustion chamber and operate in tandem with it exceptionally well.

- Cascade Cleaning System (CCS) – cascade self-cleaning grate system that evenly distributes fuel across the entire combustion area. This allows the burner to operate with low-quality pellets and effectively removes ash and other combustion residues. Cascade cleaning is recognized in the industry and by most equipment manufacturers as the most efficient and reliable solution. This system is used in all Domna burner models.

- Clever Air System (CAS) – an intelligent system for primary and secondary air distribution and proportional mixing with the fuel, enabling maximum combustion efficiency (98%) and stable operation. The system allows the burning of pyrolysis gases (from pellets) released during combustion, reducing fuel consumption and minimizing harmful emissions into the atmosphere.

- Ceramic FKK igniter (Japan) – the best igniters on the market. They ignite quickly, are very reliable, and have a long service life – over 10,000 ignitions.

- ESC (Easy Service Cleaning) – a system enabling easy access to the combustion chamber and burner grates for inspection and any required cleaning. No special tools needed. The system allows cleaning of the burner chamber without opening the boiler door, which is convenient and saves time and effort.

- Fuzzy Logic – an intelligent system for automatic burner power modulation.

- Modern control system – manage your heating and domestic hot water system via the internet or smartphone app, smart weather control – all of this is easily accessible with Domna burners.

- DSS (Domna Safety System) – a multi-level safety system for the burner, making operation safe and pleasant. Meets all fire safety standards for solid fuel combustion.

- Low emission levels – thanks to the ceramic combustion chamber, cast iron grates, and the CAS system, Domna burners emit significantly less harmful exhaust gases (CO, NOX, OGC) and dust to the atmosphere compared to solid fuel boilers or burners without these features.

- The quietest pellet feeder – the pellet feeding screw is made of high-quality plastic, making the transport process virtually silent. Its reduced friction coefficient prevents the pellet from being ground into dust and allows it to reach the combustion chamber intact. This helps solve the problem of excessive dust during combustion.

- Easily replaceable combustion chamber made of heat-resistant AISI 310S steel.

- Long service life – achieved thanks to components from global brands: Siemens, Lapp, Plum, MplusM.

- Automatic restart – automatic start and return to set operating mode after a power failure.

- Warranty – 24 months

Applications

DOMNA MAX-350 is a solution for the biggest heating challenges – large industrial facilities, district heating plants, production halls, farms, and dryers. Wherever high power, efficiency, and reliability are required, the DOMNA MAX-350 burner ensures long-term and cost-effective operation.

Thanks to its solid construction, advanced automation, and ability to work in demanding conditions, this device meets the expectations of the most demanding users.

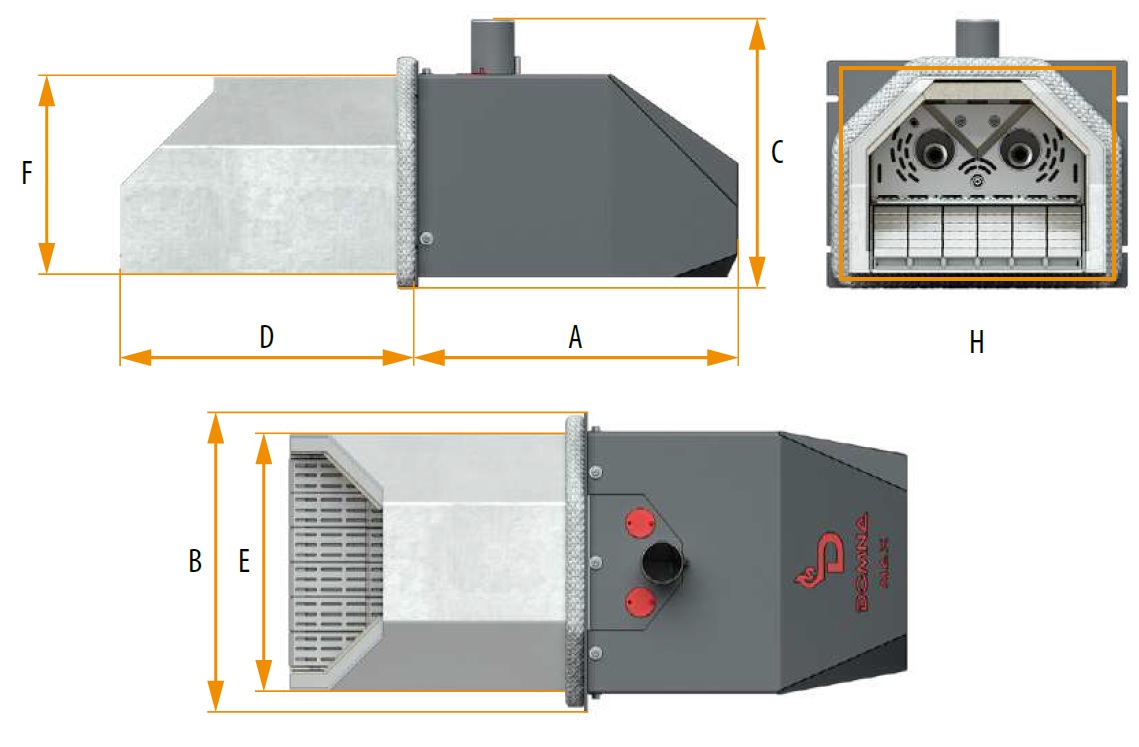

Technical drawing:

| Parameter | Domna 300 kW | Domna 350 kW | Domna 400 kW | Domna 500 kW | Domna 750 kW |

|---|---|---|---|---|---|

| Power (min-max) | 60–320 kW | 70–380 kW | 80–440 kW | 100–550 kW | 150–820 kW |

| Power supply | 230 V AC / 50Hz | 230 V AC / 50Hz | 230 V AC / 50Hz | 230 V AC / 50Hz | 230 V AC / 50Hz |

| Fuel | Pellet Ø 6–8 mm | Pellet Ø 6–8 mm | Pellet Ø 6–8 mm | Pellet Ø 6–8 mm | Pellet Ø 6–8 mm |

| Weight* | 141 kg | 157 kg | 264 kg | 289 kg | 462 kg |

| Power consumption (operation) | 315 W | 230 W | 315 W | 333 W | 416 W |

| Power consumption (ignition) | 815 W | 660 W | 815 W | 1073 W | 1156 W |

| Noise level | 45 dB | 45 dB | 45 dB | 45 dB | 45 dB |

| Length of rear part (A) [mm] | 761 | 571 | 955 | 955 | 1263 |

| Overall width (B) [mm] | 530 | 530 | 580 | 656 | 753 |

| Overall height (C) [mm] | 533 | 473 | 681 | 681 | 768 |

| Burner chamber length (D) [mm] | 338 | 520 | 289 | 289 | 384 |

| Burner chamber width (E) [mm] | 390 | 453 | 453 | 511 | 581 |

| Burner chamber height (F) [mm] | 347 | 347 | 491 | 491 | 583 |

| Burner mounting opening (H) | 397×354 | 460×354 | 460×498 | 518×498 | 347 |

| Efficiency** | up to 98% | up to 98% | up to 98% | up to 98% | up to 98% |

| Required chimney draft | 22 Pa | 22 Pa | 22 Pa | 22 Pa | 22 Pa |

| Equipped with fuel screw | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) |

| Equipped with thermoplastic pipe | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) |

| Burner power modulation | Yes | Yes | Yes | Yes | Yes |

| CO pump control | Yes | Yes | Yes | Yes | Yes |

| DHW pump control | Yes | Yes | Yes | Yes | Yes |

| Room thermostat control | Yes (optional) | Yes (optional) | Yes (optional) | Yes (optional) | Yes (optional) |

| Weather sensor control | Yes (optional) | Yes (optional) | Yes (optional) | Yes (optional) | Yes (optional) |

*Without screw feeder and controller

** Depends on boiler and heating system

Want more information about this device?

Contact us – we'll advise the best solution for you!

Contact us