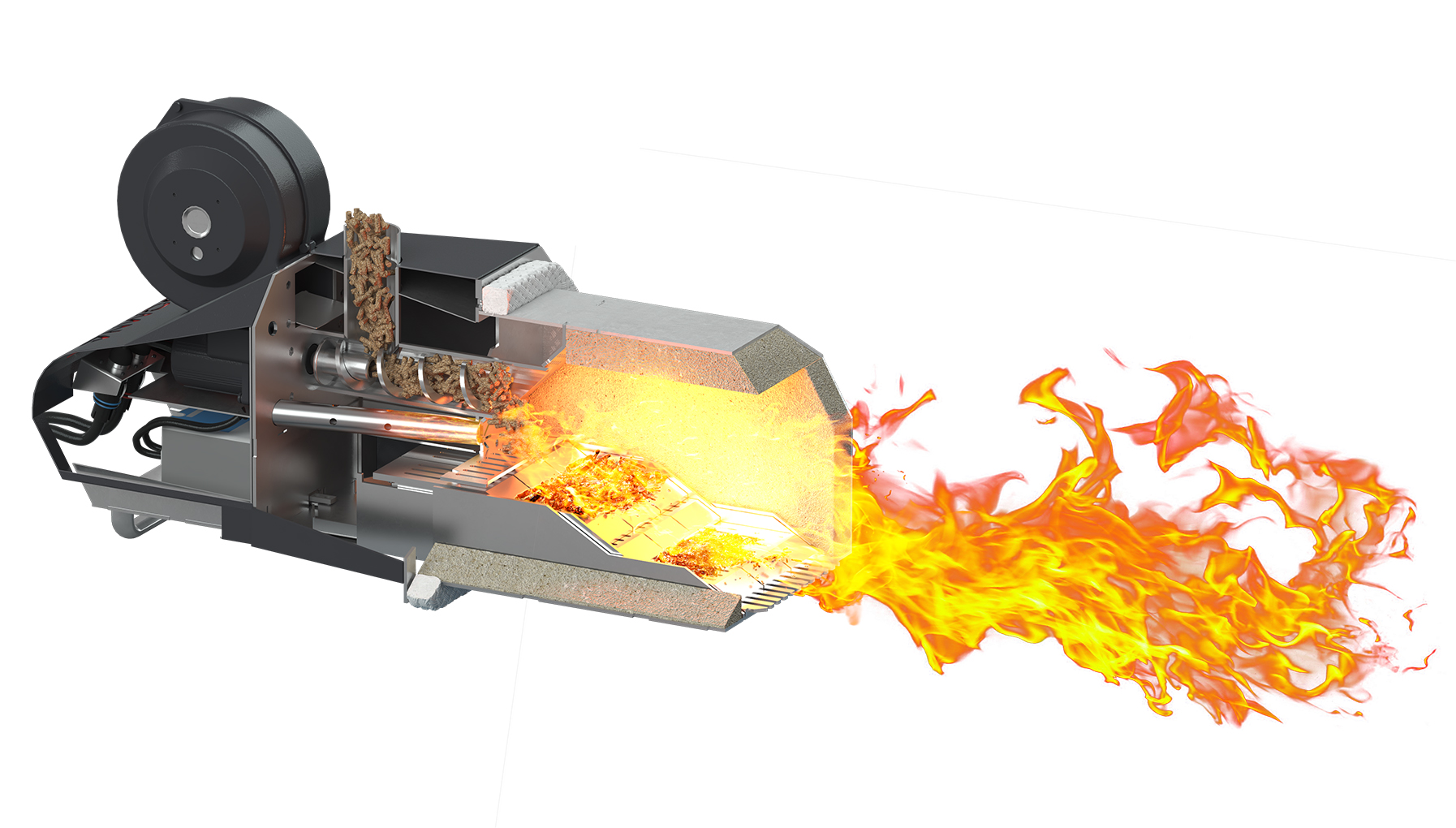

Pellet burner DOMNA PRO 250 KW

- Product Code: DOMNA-250

Description

DOMNA PRO 250 kW pellet burner is a modern, industrial heating device from TechnoMaszBud, dedicated to users looking for an efficient and ecological heat source. The 250 kW power makes it an excellent solution for large spaces – such as warehouses, greenhouses, manufacturing plants, farms or larger residential buildings.

DOMNA PRO 250 kW is equipped with an automatic ignition system, a precise controller, and an efficient self-cleaning system. Thanks to this, it offers high user convenience with minimal user involvement. The control system with power modulation and the ability to cooperate with additional sensors guarantees efficiency up to 98%, which translates into real energy savings.

You can test this machine on your material at our warehouse!

Principle of Operation

Pellets are delivered to the burner by a feed auger Ø76 mm, where they are ignited and burned in the combustion chamber. The fan provides controlled air supply, allowing for efficient and clean combustion. The generated heat is transferred to the boiler or heating system.

The burner is managed by an advanced controller, which supervises all processes: fuel feeding, water temperature, air supply, and the burner’s operating mode.

Set includes:

- Domna PRO 250 kW burner

- Controller with a set of sensors

- Feed auger Ø76 x 2000 mm

- Pipe Ø76 x 1000 mm

- User manual

- (Optional: rotary safety valve)

Main Advantages of the DOMNA PRO 250 kW Pellet Burner

- Ceramic combustion chamber in all burner models – ensures full and qualitative combustion of fuel thanks to the formation of a thermal core. The heat is not transferred to the burner housing and thus does not damage it, but remains inside the combustion chamber, acting as a catalyst for complete fuel combustion. The flame from such a chamber is cleaner, and the amount of ash and slag from low-quality fuel is reduced.

- Cast iron grates – they do not burn out or deform at high temperatures, unlike stainless steel or regular steel grates. Cast iron grates perfectly maintain the high temperature generated by the ceramic combustion chamber and work excellently with it in tandem.

- Cascade Cleaning System (CCS) – a cascade self-cleaning system for grates from ash, evenly distributes fuel over the entire combustion surface. It enables the burner to operate with low-quality pellets and effectively removes ash and other combustion residues. Cascade cleaning is recognized in the market and by most device manufacturers as the most effective and reliable solution. This is the system used in all Domna burner models.

- Clever Air System (CAS) – intelligent system for distributing primary and secondary air and proportionally mixing it with fuel, allows for maximum combustion efficiency (98%) and work stability. The system allows the combustion of pyrolysis (pellet) gases released during pellet combustion, which reduces fuel consumption and minimizes harmful emissions into the atmosphere.

- Ceramic igniter FKK (Japan) – the best igniters available on the market. They work quickly, are very reliable, and have a long service lifespan – over 10,000 ignitions.

- ESC (Easy Service Cleaning) – easy access system to the combustion chamber and grate block for service and cleaning. No special tools are needed. The system allows cleaning of the burner chamber without opening the boiler door, which is very convenient and saves time and effort.

- Fuzzy Logic – intelligent system of automatic burner power modulation.

- Modern control system – allows you to manage the heating and domestic hot water system via the internet or a mobile app, intelligent weather-based control – all this is easily available with Domna burners.

- DSS (Domna Safety System) – multi-level burner safety system, making its operation pleasant and safe. Meets all fire safety standards for solid fuel combustion.

- Low emissions – thanks to the ceramic combustion chamber, cast iron grates, and the CAS system, Domna burners emit significantly fewer harmful exhaust gases (CO, NOX, OGC) and dust into the atmosphere compared to typical solid fuel boilers or burners without these elements.

- The quietest pellet feeder – the pellet feeding auger made from high-quality plastic makes the transportation process virtually silent. Additionally, it has a reduced friction coefficient, so the pellet does not get ground to dust and reaches the combustion chamber intact. This helps solve the problem of excessive dust during combustion.

- Easy-to-replace combustion chamber made from heat-resistant AISI 310S steel.

- Burners are characterized by long service life – thanks to the use of components from world brands: Siemens, Lapp, Plum, MplusM.

- Automatic restart – automatic start-up and return to the set mode after a power outage.

- Warranty – 24 months.

Applications of the DOMNA PRO 250 kW burner

The burner is used in large buildings: industrial halls, farms, bakeries, boiler rooms, dryers, and wherever a reliable, high-power heat source is required.

It can be installed both in new and existing solid-fuel boilers with a capacity of 150–250 kW.

Technical drawing:

| Parameter | Domna 100 kW | Domna 150 kW | Domna 200 kW | Domna 250 kW |

|---|---|---|---|---|

| Power (min-max) | 20–110 kW | 30–160 kW | 40–240 kW | 50–270 kW |

| Mains voltage | 230 V AC / 50Hz | 230 V AC / 50Hz | 230 V AC / 50Hz | 230 V AC / 50Hz |

| Fuel | Pellet Ø 6–8 mm | Pellet Ø 6–8 mm | Pellet Ø 6–8 mm | Pellet Ø 6–8 mm |

| Weight | 55 kg | 62 kg | 107 kg | 113 kg |

| Power consumption (operation) | 100 W | 130 W | 180 W | 180 W |

| Power consumption (ignition) | 397 W | 500 W | 583 W | 583 W |

| Noise level | 51 dB | 51 dB | 51 dB | 51 dB |

| Rear section length (A) [mm] | 625 | 561 | 752 | 513 |

| Total width (B) [mm] | 361 | 361 | 530 | 530 |

| Total height (C) [mm] | 481 | 481 | 533 | 533 |

| Burner chamber length (D) [mm] | 300 | 315 | 276 | 515 |

| Burner chamber width (E) [mm] | 229 | 281 | 332 | 332 |

| Burner chamber height (F) [mm] | 264 | 264 | 321 | 347 |

| Burner mounting opening (H) | 236×270 | 288×270 | 340×355 | 340×355 |

| Efficiency** | up to 98% | up to 98% | up to 98% | up to 98% |

| Required chimney draft | 22 Pa | 22 Pa | 22 Pa | 22 Pa |

| Equipped with fuel auger | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) | Yes (Ø76×2000 mm) |

| Equipped with thermoplastic pipe | Yes (Ø76×1000 mm) | Yes (Ø76×1000 mm) | Yes (Ø76×1000 mm) | Yes (Ø76×1000 mm) |

| Burner power modulation | Yes | Yes | Yes | Yes |

| CO pump control | Yes | Yes | Yes | Yes |

| DHW pump control | Yes | Yes | Yes | Yes |

| Room thermostat control | Yes (optional) | Yes (optional) | Yes (optional) | Yes (optional) |

| Weather sensor control | Yes (optional) | Yes (optional) | Yes (optional) | Yes (optional) |

*Without feed auger and controller

** Dependent on boiler and heating system

Need more information about this device?

Contact us – we will advise the best solution for you!

Contact us