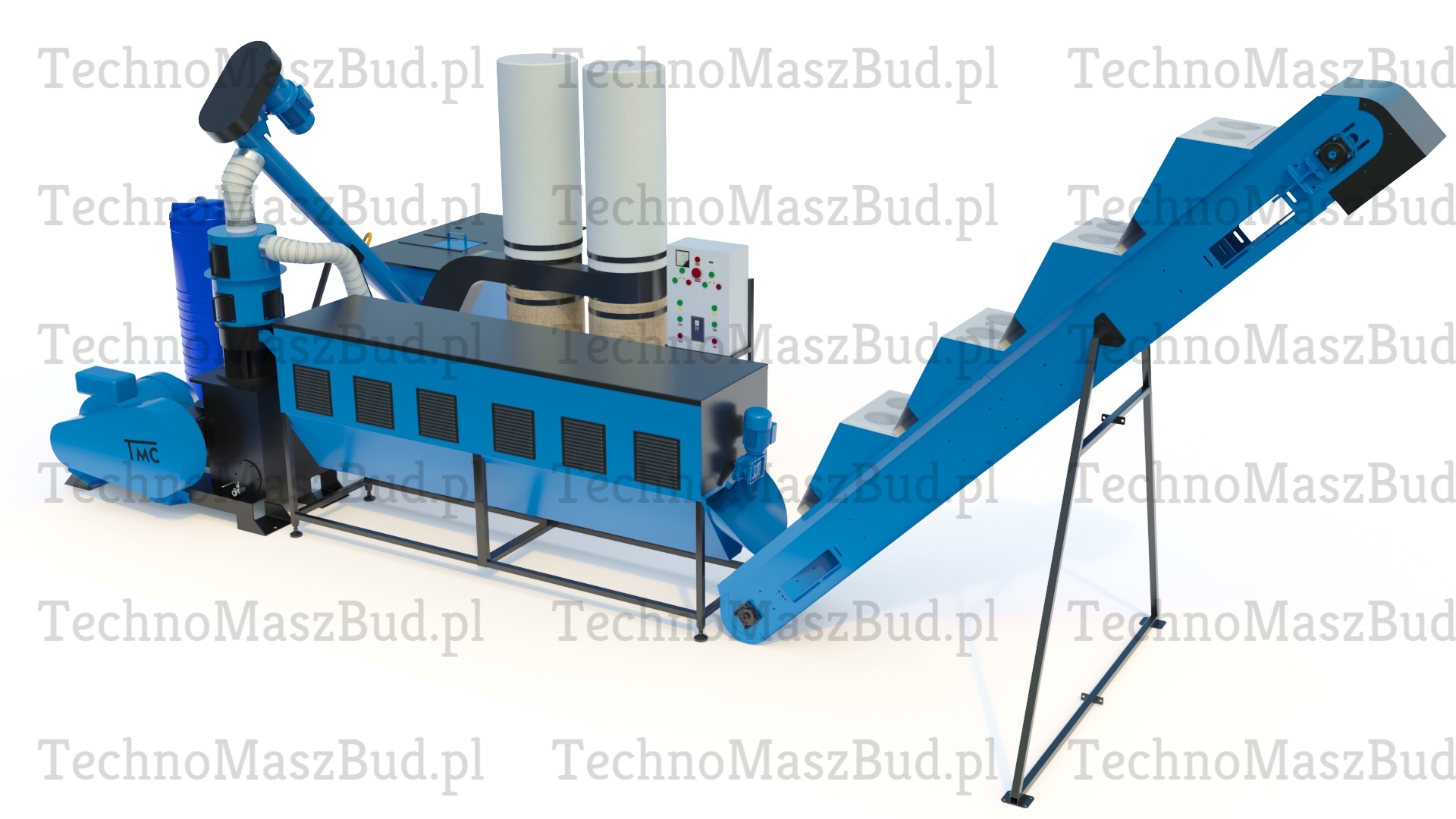

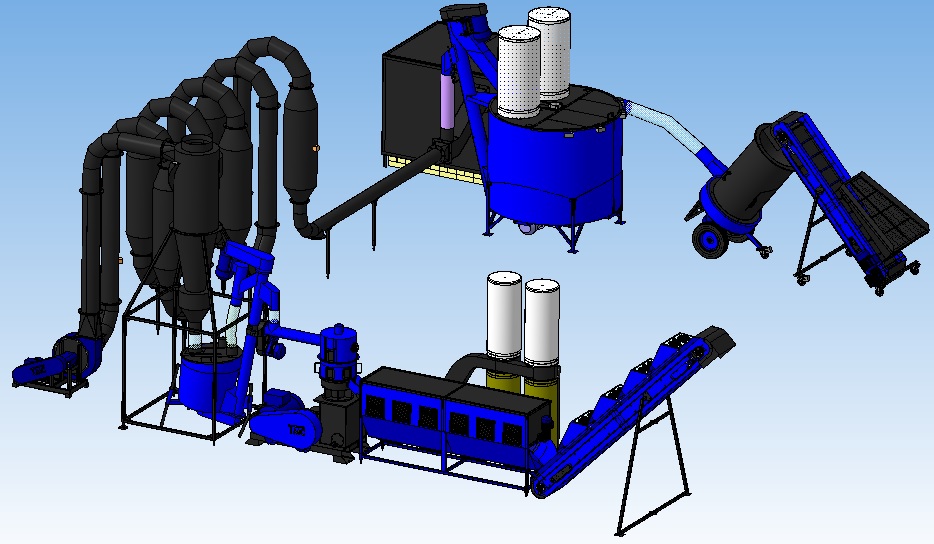

Granulation Line LDG-4000 (KOMBI)

In Stock

Available Options

- Product Code: LDG-4000_KOMBI

Main characteristics

All specifications

Length:

400.0(cm)

Width:

330.0(cm)

Height:

230.0(cm)

Weight:

1400.0(kg)

Product type:

Granulation line / Pellet Mill line

Description

The granulation line LDG-4000 KOMBI is based on the PRIME-400 granulator.

In the presented pellet production line, we combined the feed auger and mixer into one system for feeding raw materials to the

granulator. Additionally, the set includes a humidifier for moistening the raw materials if the raw materials are too dry. Thanks to this

solution, advantages such as practicality, ergonomics and small size were achieved. Combining the two systems made it possible to reduce

energy consumption costs.

The LDG-4000 KOMBI line includes:

1. PS-200 screw feeder.

It consumes 0.75 kW of electricity and has smooth control of the raw material supply speed using a frequency converter.

2. Humidification system.

The main elements of the system are: valve, pump, water tank for 100 liters and nozzle. It is connected to a stand above the work area,

allowing the required, measured amount of moisture to be added during granulation. Power consumption - 0.37 kW.

3. Granulator PRIME-400.

This granulator easily copes with various types of raw materials, achieving a productivity of up to 500 kg/hour for sawdust pellets and up to

550 kg/hour for feed pellets. A 37 kW pellet engine is used.

4. Calibrator- cooler KC-200.

It serves as additional cooling of the product since the pellets heat up during the granulation process. This device also removes dust and

crumbs using a special drum. Power consumption - 0.12 kW.

5. Closed SO-2 extraction system.

This device, using a fan, circulates the air necessary to cool the granules and collect calibrated residues of raw materials and dust into a

container in the form of bags that are attached to it. Dust in special dust collectors can be reused in production. Power - 1.5 kW.

6. Control Panel.

Small dimensions and a built-in automation cooling system make the control panel reliable and convenient for installation near the

production line. The panel contains an ammeter and thermal protection for each motor in the line.

The conveyor belt and cables for connecting the line are not included in the set.

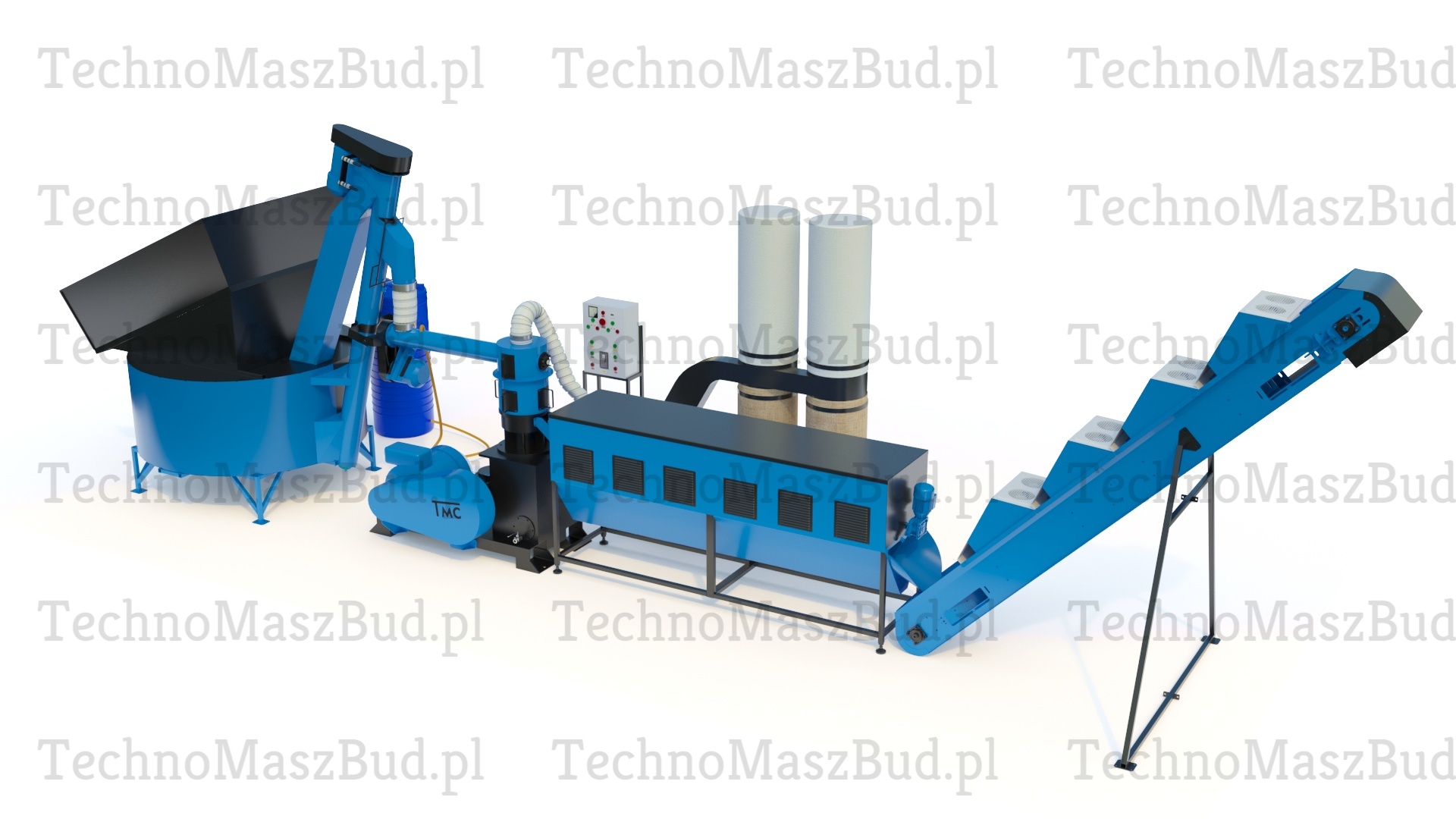

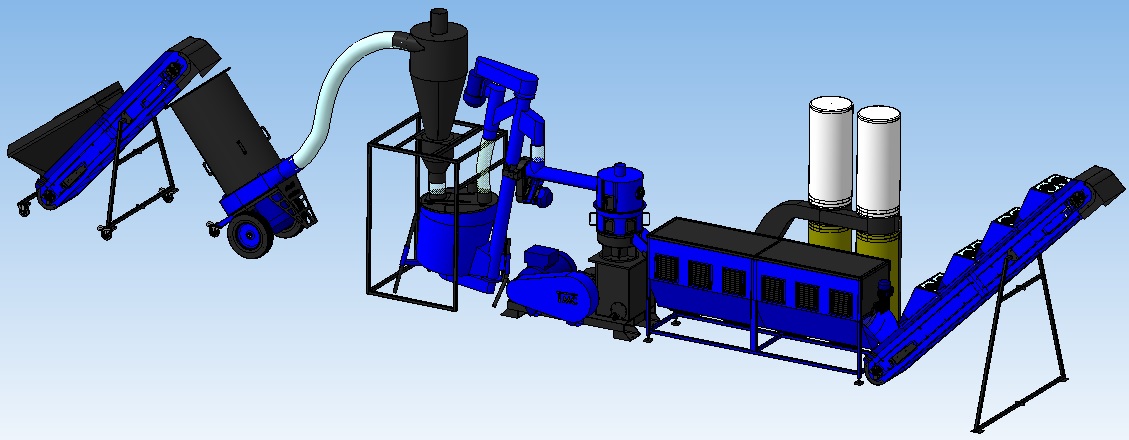

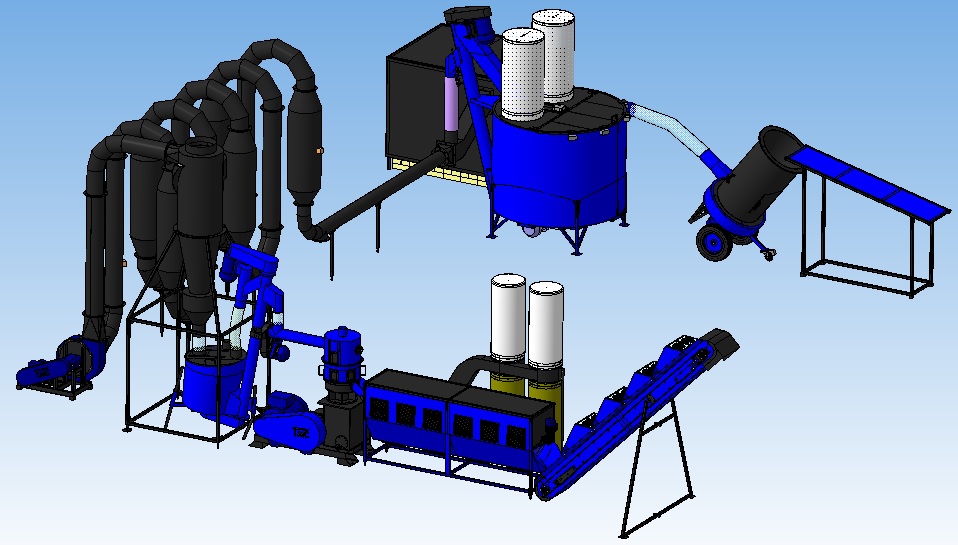

Possible variants of pellet production line sets:

1. The LDG-4000 KOMBI line.

2. Line LDG-4000 KOMBI 40 Kw + Belt Conveyor PT-500 with fans.

3. LDG-4000 line with a calibrator bunker (equipped with a mesh to filter bark, pieces of wood, branches, garbage) + PT-500 Belt Conveyor

with fans.

4. Line LDG-4000 KOMBI 40 Kw + Belt Conveyor PT-500 with fans + Shredder RD-1000 with a cyclone.

5. Line LDG-4000 KOMBI 40 Kw + PT-500 belt conveyor with fans + Shredder RD-1000 with cyclone + PT-1000 conveyor belt.

6. Line LDG-4000 KOMBI 40 Kw + PT-500 Belt Conveyor with fans + SA-600 Aerodynamic Sawdust Dryer.

7.Line LDG-4000 KOMBI 40 Kw + PT-500 Belt Conveyor with fans + Shredder RD-1000 + SA-600 Aerodynamic Sawdust Dryer with

MAX+ Feeder.

8. Line LDG-4000 KOMBI 40 Kw + Belt Conveyor PT-500 with fans + Shredder RD-1000 + Conveyor belt PT-1000 +

Aerodynamic Dryer for Sawdust SA-600 with Feeder MAX +.

What raw material can be processed with our LDG-4000 KOMBI line?

The equipment can easily process sawdust from hard and softwood trees, grain waste, chaff, grass, hay, seed husks, feed mixtures with

grain composition, and plastic production waste.

Finished products that can be obtained with the LDG-4000 KOMBI line:

• Pellets made from sawdust, shavings, dust from deciduous and coniferous trees and MDF boards;

• Biomass pellets (straw, branches, wood chips);

• Granulates from plant waste (sunflower husks, buckwheat, other plant species), which are used in the energy industry;

• Granular feed with a homogeneous structure, the digestibility of which is 90%;

• Plastic granules which are further used in the production of pipes.

Technical data LDG-4000 KOMBI:

The line is equipped with a PRIME-400 granulator with a capacity of up to 500 kg of product per hour. The engine power is 37 KW, powered

by a 380 V network.

Additionally, you can order spare parts for the equipment from us, for example a set of matrix with holes for 2 mm, 3 mm, 4 mm,

5 mm, 6 mm and 8 mm. This makes it possible to produce granules of various sizes.

Our customers can order any part for the LDG-4000 KOMBI line.

Specification

Dimensions

Length

400.0(cm)

Width

330.0(cm)

Height

230.0(cm)

Weight

1400.0(kg)

Key features

Product type

Granulation line / Pellet Mill line

The diameter of radial holes in the die

from 2 to 8 mm (optional)

Usage

For production of granular nutriment and pellets

Type of drive

Electric

Production capacity

up to 500.0(kg/h) - feed

up to.0(kg/h) - pellets

Engine power

37(kw)

Power consumption

39,74 (kW)

Voltage

380.0(W)

Rotation speed

1500 revolutions

The diameter of the die

400(mm)

The number of knives

1(PCs)

Additional features

The number of rolls

2(PCs)

Extended bunker

Yes

Warranty

12 months

Dimensions

Length

400.0(cm)

Width

330.0(cm)

Height

230.0(cm)

Weight

1400.0(kg)

Key features

Product type

Granulation line / Pellet Mill line

The diameter of radial holes in the die

from 2 to 8 mm (optional)

Usage

For production of granular nutriment and pellets

Type of drive

Electric

Production capacity

up to 500.0(kg/h) - feed

up to.0(kg/h) - pellets

Engine power

37(kw)

Power consumption

39,74 (kW)

Voltage

380.0(W)

Rotation speed

1500 revolutions

The diameter of the die

400(mm)

The number of knives

1(PCs)

Additional features

The number of rolls

2(PCs)

Extended bunker

Yes

Warranty

12 months

Tags: Granulators, Pellet mills, PRIME, LDG