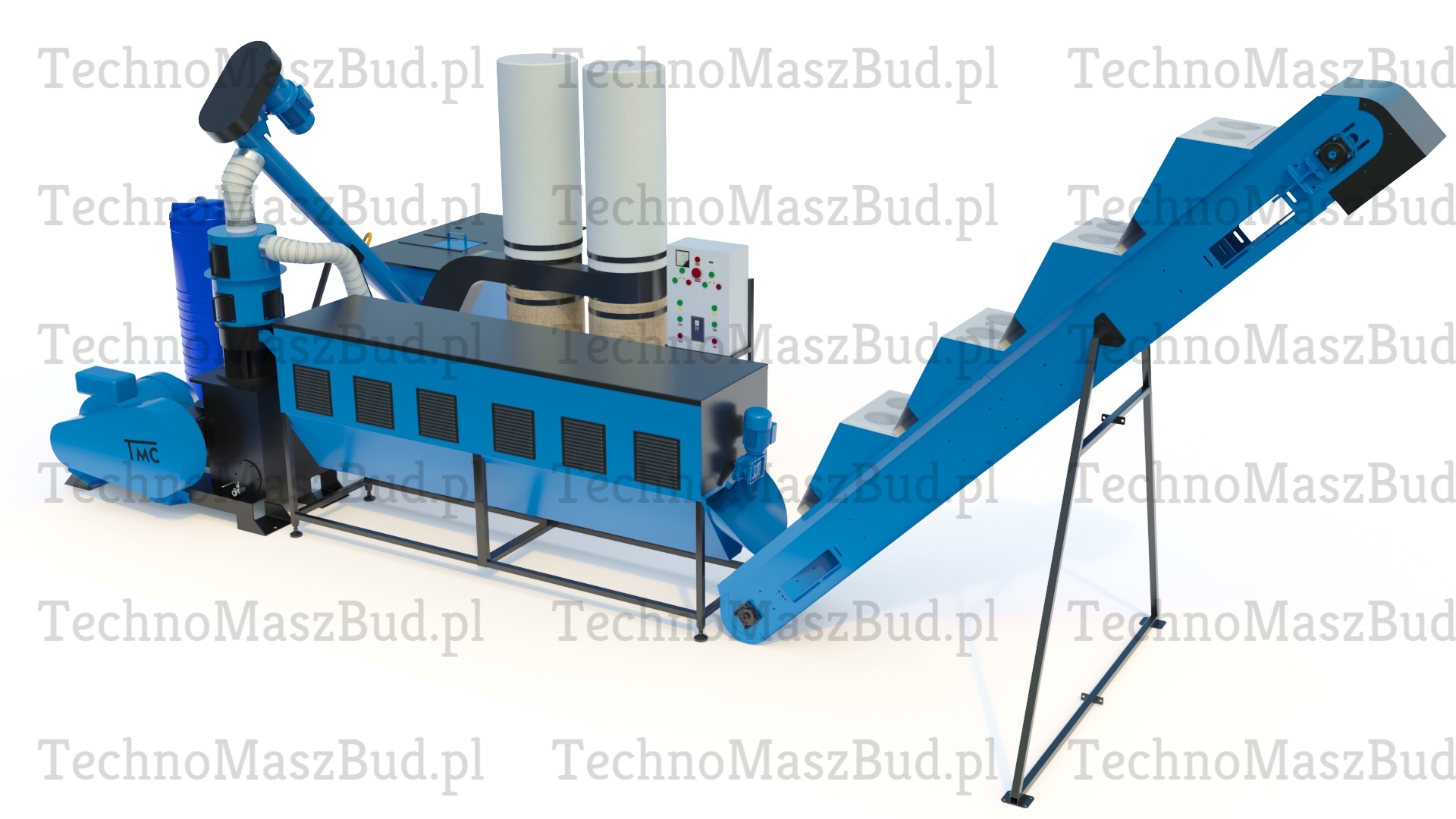

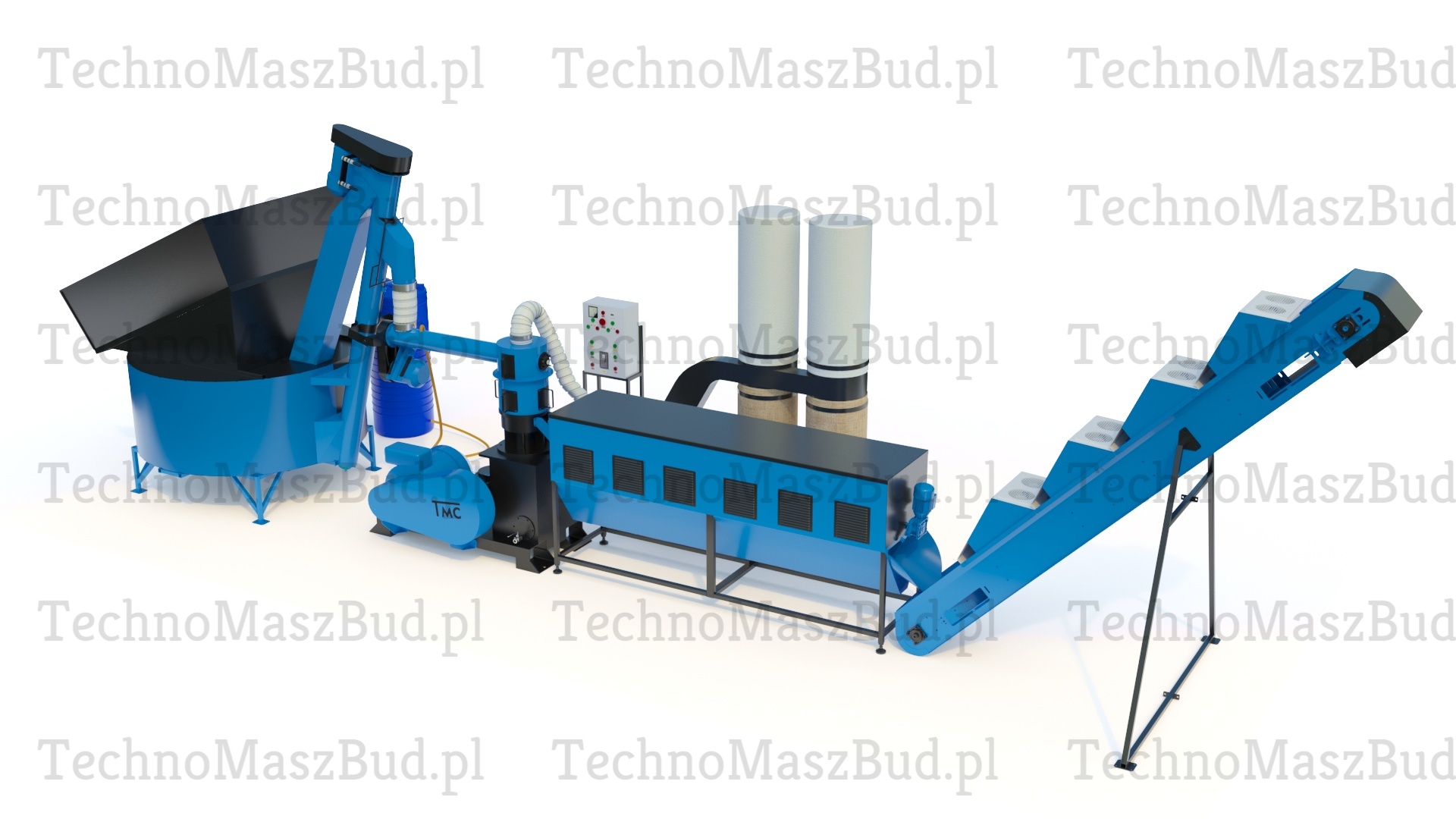

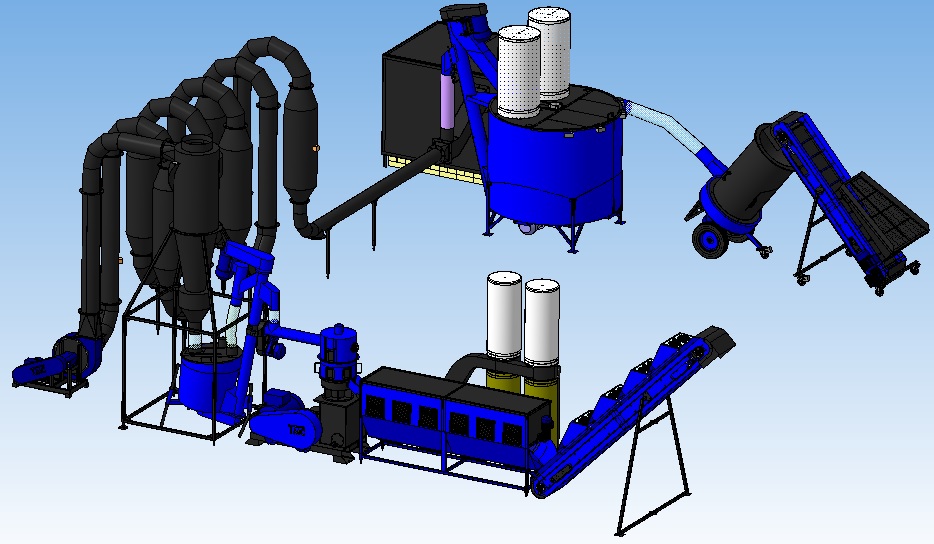

Granulation Line LDG-4000 (KOMBI)

Available Options

- Product Code: LDG-4000_KOMBI

Description

LDG-4000 KOMBI Pellet Production Line is a modern and versatile technological solution that enables the granulation of various raw materials. The machine is intended for the production of pellets with a diameter from 2 mm to 8 mm, allowing for the manufacture of both wood fuel pellets and pelleted animal feed. The line’s capacity reaches up to 700 kg/h for feed production and up to 650 kg/h for pellet production, making it a reliable solution for the agricultural, woodworking, sawmill, and energy industries.

IT IS POSSIBLE TO TEST THIS MACHINE WITH YOUR RAW MATERIAL AT OUR WAREHOUSE!

The LDG-4000 KOMBI pellet production line equipped with the PRIME-400 pelletizer is a modern biomass granulation set.

This equipment differs from the LDG-3000 KOMBI granulation line mainly by the use of a more powerful pelletizer. The granulation line can be used both for pellet and compound feed production — for your own needs or in commercial operations.

For your convenience, we offer not only the selection of the appropriate line for your requirements, but also assistance with installation, commissioning, and achieving the expected results!

The LDG-4000 KOMBI line includes:

This component consumes 0.75 kW of electricity and allows smooth raw material feed rate adjustment via a frequency converter.

2. Moisturizing system:

The main elements of the moisturizing unit are a valve, pump, 100-liter water tank, and nozzle. The system is connected to a stand above the working area, enabling the required moisture to be added during granulation. Power consumption is 0.37 kW.

3. Reliable PRIME-400 pelletizer:

The PRIME-400 granulator easily handles various types of raw materials, reaching a capacity of up to 650 kg/h for sawdust pellets and up to 700 kg/h for feed granules. It is equipped with a 37 kW motor.

4. Granule/Pellet Calibrator-Cooler KC-200:

This component additionally cools the product, since pellets heat up during pelleting. The device removes dust and crumbs with a special drum. Power usage is 0.12 kW.

5. Closed Extraction System SO-2:

This device, using a fan, provides air circulation necessary for cooling the granules, and collects calibrated raw material residues and dust into bags attached to the casing. The system’s power is 1.5 kW.

6. Control panel:

Thanks to its small dimensions and built-in automation cooling system, the control panel is reliable and easy to install near the production line. It includes an ammeter and thermal protection for each motor in the line.

The belt conveyor is not included in the set

Cables for connecting the line are not included in the set

LDG-4000 KOMBI Pellet Production Line Performance:

- wood waste – up to 650 kg/h,

- straw – up to 550 kg/h,

- feed – up to 700 kg/h,

- sunflower husks – up to 550 kg/h.

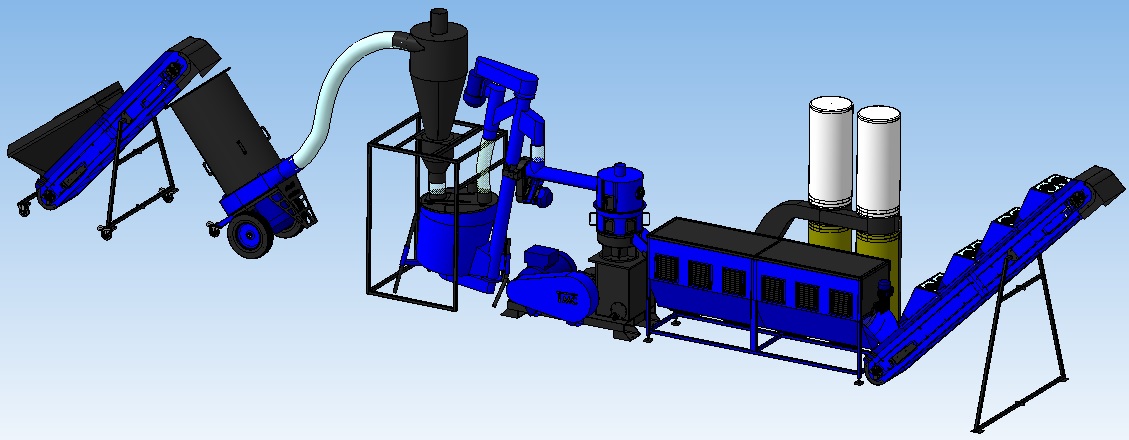

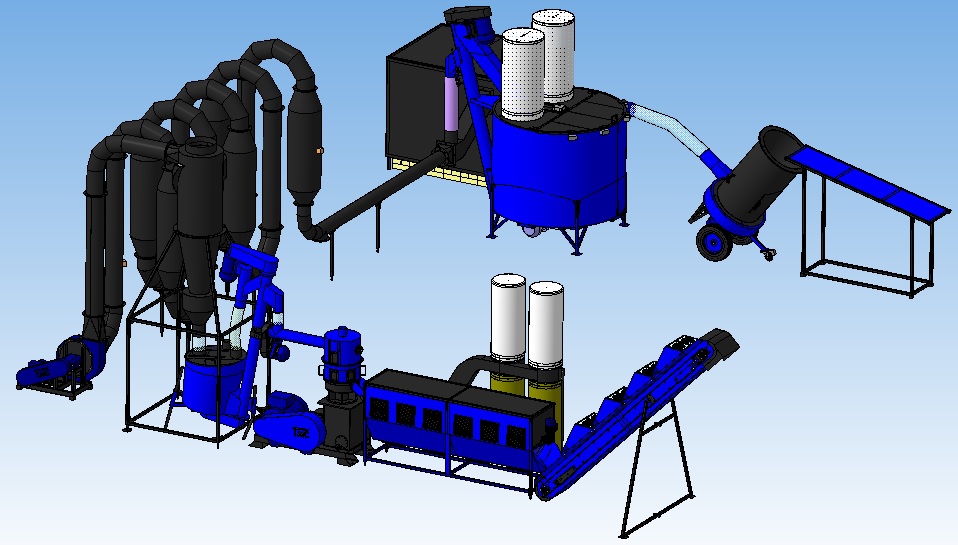

Types of LDG-4000 KOMBI lines:

There are several configurations of the LDG-4000 KOMBI line available, differing in, among others, adaptation to individual production needs: additional conveyors, shredders, dryers, or calibrators. The client has the option of selecting the most suitable set—from the basic version to fully automated systems with an SA-400 Aerodynamic Dryer and RD-500 Shredder.

1. LDG-4000 KOMBI Line

2. LDG-4000 KOMBI Line 40 kW + PT-500 Belt Conveyor with fans

3. LDG-4000 Line with calibrating hopper (equipped with a mesh to filter out bark, pieces of wood, branches, debris) + PT-500 Belt Conveyor with fans

4. LDG-4000 KOMBI Line 40 kW + PT-500 Belt Conveyor with fans + RD-1000 Shredder with cyclone

5. LDG-4000 KOMBI Line 40 kW + PT-500 Belt Conveyor with fans + RD-1000 Shredder with cyclone + PT-1000 Conveyor-Calibrator.

6. LDG-4000 KOMBI Line 40 kW + PT-500 Belt Conveyor with fans + SA-600 Aerodynamic Sawdust Dryer

7. LDG-4000 KOMBI Line 40 kW + PT-500 Belt Conveyor with fans + RD-1000 Shredder + SA-600 Aerodynamic Sawdust Dryer with MAX Feeder+

8. LDG-4000 KOMBI Line 40 kW + PT-500 Belt Conveyor with fans + RD-1000 Shredder + PT-1000 Conveyor-Calibrator + SA-600 Aerodynamic Sawdust Dryer with MAX Feeder+

What raw materials can be processed by our LDG-4000 KOMBI line?

The equipment easily processes hardwood and softwood sawdust, cereal waste, hulls, herbs, hay, seed husks, compound feed mixtures of cereal composition, as well as waste from plastics manufacturing.

Finished products obtained from the LDG-4000 KOMBI line

With the LDG-4000 KOMBI line you can produce a wide range of granulated products tailored to different industries:

- Wood pellet – from sawdust, shavings and dust of deciduous, coniferous trees and MDF boards.

- Biomass pellet – from straw, branches, chips and other plant materials.

- Energy plant granules – from sunflower hulls, buckwheat and other plants, used in the energy sector.

- Compound feed – with uniform structure and high digestibility up to 90%, intended for breeders and feed manufacturers.

- Plastic granulate – secondary raw material that can be reused, e.g. for the production of pipes and other technical products.

Thanks to this line, you can not only solve the waste disposal problem, but also reduce production costs and turn waste into a source of real profit.

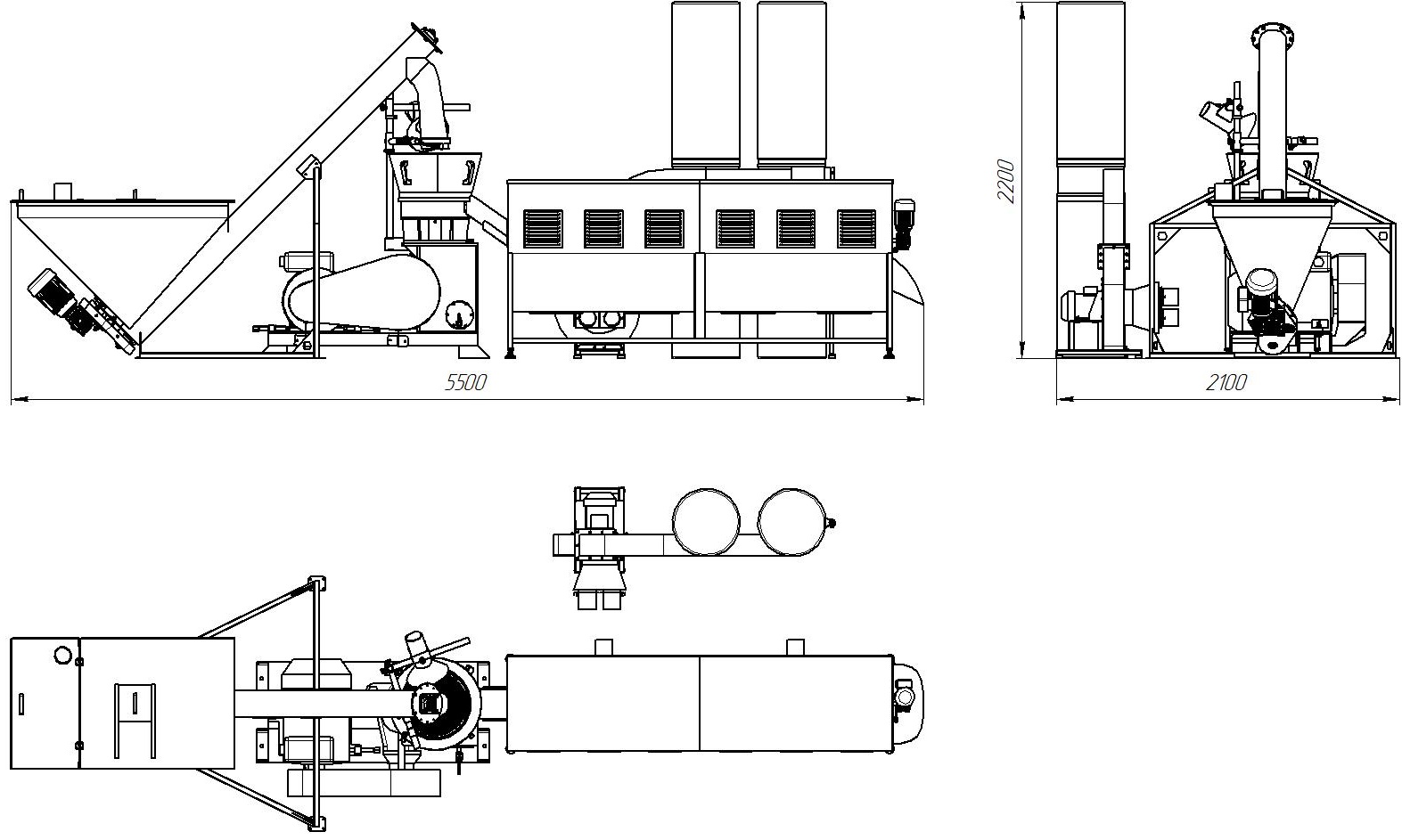

Technical drawing:

Technical Support and Training

With the delivery, we provide professional technical support, help with installation and commissioning, as well as staff training. This ensures confidence in correct operation and maximum efficiency in everyday use.

Applications

LDG-4000 KOMBI Pellet Production Line has applications in many industries, including: fuel pellet production from sawdust, shavings, chips; straw and agricultural biomass granulation; pelleted animal feed production; organic waste processing; plastics granulation (e.g. for the manufacture of industrial components).

Pellet production lines from the LDG series guarantee high quality, flexibility and savings – the perfect solution for companies looking for reliable technology for pellet and feed granulation.

The LDG-4000 KOMBI line can be installed even in a small room, which allows you to significantly reduce fixed costs related to renting or maintaining a large production hall.

We also offer a full range of spare parts for this device – including die sets with hole diameters of 2 mm, 3 mm, 4 mm, 5 mm, 6 mm and 8 mm, which enable the production of pellets of different sizes and purposes.

Our customers can order any part for the LDG-4000 (KOMBI) line directly from our company – we provide fast order fulfillment and professional technical advice.

Need more information about this device?

Contact us – we will advise you on the best solution!

Contact us