Weighing / Bagging machine WP-1000

- Product Code: WP-1000

Description

The WP-1000 Bagging Machine is a semi-automatic machine designed for precise packaging and dosing of bulk products and raw materials.

It provides exceptional precision and repeatability of the process. The device quickly and efficiently fills ready-made polyethylene foil and polypropylene bags, guaranteeing high efficiency and reliability in packaging a wide range of products.

This bagging machine operates in semi-automatic mode. The operator plays a crucial role in its operation – their job is to place the packaging, start the dosing process, and collect the filled product. This allows the production facility to have complete control over every stage of packaging, increasing both precision and reliability of the device's performance.

The WP-1000 dispenser covers a weighing range from 0.15 to 50 kg, allowing for exact packaging of various bulk products, including fuel pellets, feed granules, groats, short pasta, nuts, and seeds. The entire process is under precise and rigorous weight control, and the device’s accuracy meets accepted standards, ensuring repeatability and high packing quality. After filling, the package can be hermetically sealed using an ZW-500 impulse sealer, guaranteeing durability and protection against external factors.

It is possible to test this machine on your raw material in our warehouse!

Advantages of the WP-1000 bagging machine

- Dosing precision – electronic weighing system provides exceptional packaging accuracy in the range of 0.15–50 kg

- Versatility of applications– perfect for packing pellets, groats, agricultural produce, grains, pasta, coffee, and building mixtures

- Semi-automatic operation– operator has full control of each packaging process stage

- Large feeder– a 125-liter tank is an optimal solution for mid-scale production

- Function extension option– cooperation with the ZW-500 sealer enables airtight package sealing

- Multilingual interface– the system supports Polish, English, German, Russian, and Romanian languages

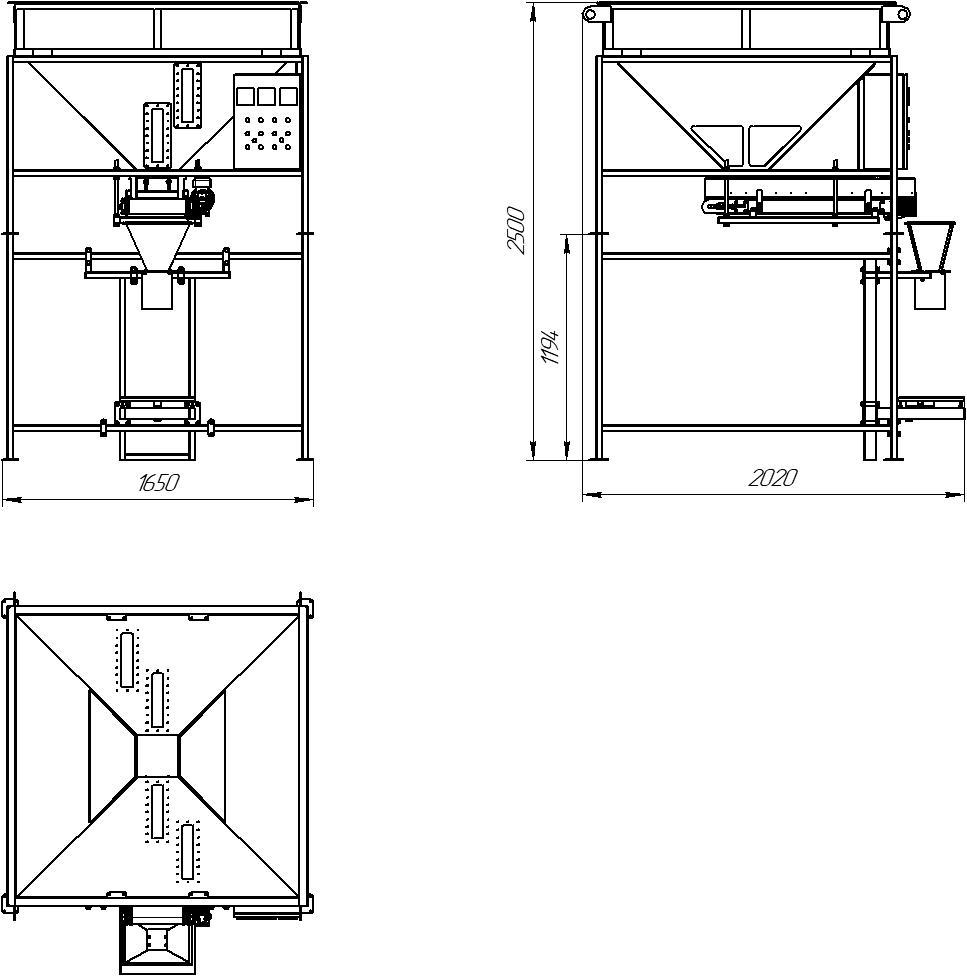

Technical drawing:

Applications of the WP-1000 bagging machine:

The WP-1000 bagging machine will work well in food processing facilities, in the feed industry, agriculture and the chemical industry – basically anywhere that precision and efficiency in loose material packaging are key.

This bagging machine is perfect for packing:

- Grains (e.g. buckwheat, rice, oatmeal)

- Pasta

- Coffee beans

- Building mixtures (when using a non-perforated feeder)

- Pellets

Thanks to its versatility and high precision, the device is an indispensable solution in the product packaging process.

Technical parameters:

- Power supply – 230 V / 50 Hz;

- Energy consumption – 0.5-1 kWh;

- Tank capacity – 1000 l;

- Weight – 250 kg;

- The number of dosings depends on the mass and volume of the portion;

- Weighing range – 0.15-50 kg;

- Controller language: Polish / English / Romanian / German / Russian.

Need more information about this device?

Contact us – we will advise you on the best solution!

Contact us