ZPK-1 - coating and flavouring line for pet food

- Product Code: ZPK-1

Description

ZPK-1 is a modern line designed for coating and flavoring dry pet food—both for domestic animals (dogs and cats) and livestock (fish, goats, cattle). The device has been designed with a wide range of applications in mind, depending on different production requirements.

The set consists of three modules: a rotary drum with spray nozzles for liquids, the UWD-2 feeder for dry ingredients, and a mixing drum.

This enables independent operation (e.g., with only liquids or only dry additives), or full operation—combining processes in one line.

Precise adjustment of parameters (rotation, dosing, inclination angle) guarantees high quality and repeatable results. The system works as a perfect complement to devices such as a feed extruder, dog food extruder, cat food extruder, or extruder for producing fish and cattle feed.

The coating and flavoring line for pet food consists of several equipment units, each fulfilling specific functions and connected into one technological line. The main goal of the complex is dosing and uniform mixing of moist and dry ingredients with the product. It includes three main elements: drum no. 1, the UWD-2 dry and liquid ingredient supply system, and drum no. 2. The set is equipped with a control panel for the whole complex.

- Drum no. 1 – liquid ingredients such as oil or fat are introduced here. Thanks to adjustable drum speed, the possibility of setting the inclination angle, and programmed liquid dosing, the product is evenly coated with additives. This allows the recipe to be maintained and ensures better adherence of dry ingredients at the next stage.

- UWD-2 feeding system – a key component of the line. The dosing program for both liquid and dry additives is configured via the control panel. The mobile design allows operation with one or two drums as well as flexible dosing (only liquid, only dry, or both at the same time). In the DPP complex, two drums work simultaneously: liquid is added to drum no. 1, and dry ingredients are applied in the trough as the product is transported to drum no. 2.

- Drum no. 2 – thanks to its special design and geometry, it provides gentle, uniform, and high-quality mixing of dry additives with the product. The preceding moistening increases adhesion. Adjustment of speed, inclination angle, and large drum diameter make it easy to optimally select mixing and product discharge modes.

It is possible to test this machine on your raw material at our warehouse!

Main advantages of the ZPK-1 pet food flavoring line

- Possibility of coating with both liquids (oils, fats) and powdery ingredients (spices, vitamins)

- Full or modular mode operation—guarantees flexibility

- Precise dosing: accuracy up to 0.2%

- Large tanks: 50 l for liquids and 55 l for dry ingredients

- Quiet and energy-saving operation—power consumption up to 1 kW

- Compatible with ESK series pet food extruders and ST-15 food dryers

- Ideal for small and medium pet food producers

Applications

ZPK-1 is a reliable device for producing dog and cat food and also livestock feed, including fish, goats, and cattle. Combined with ESK series feed extruders and dryers for pet food, it is an integral part of a complete technological line.

Thanks to precise control over the coating process, the set allows the food to be enriched with valuable ingredients, improves taste, and extends the shelf life of the final product. ZPK-1 guarantees the highest quality and affordable production costs.

Applications of the coating complex:

- snacks and treats,

- crackers and other baked goods,

- ready meals,

- popcorn,

- nuts,

- coffee and tea,

- pet food and treats,

- animal bedding,

- and other products.

Technical parameters:

- Capacity: from 100 to 1000 l/h

- Optimal drum rotation speed: 8 rpm

- Liquid tank capacity: 50 l

- Dry ingredient tank capacity: 55 l

- Dosing accuracy: 0.2%

- Power consumption: max 4.14 kW (380-400 V)

- Weight: 725 kg

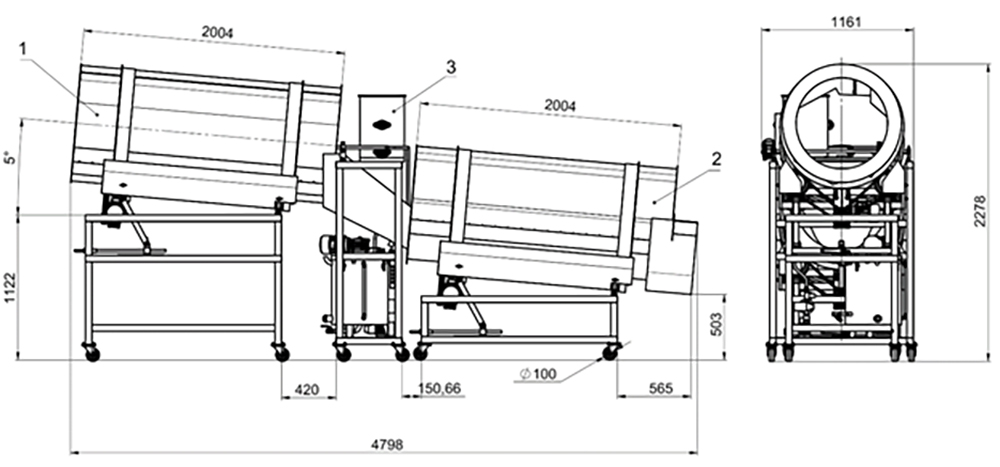

Technical drawing:

Do you need more information about this device?

Contact us—we will advise you on the best solution!

Contact us