Aerodynamic Sawdust Dryer SA-600 PRO

- Product Code: SA-600-PRO

Description

SA-600 Pro Dryer is a proven machine designed for drying various types of plant materials in fine form – sawdust, wood chips, straw, or cereal waste. It is most often used when raw material needs to be prepared for the production of pellets, briquettes, or further processing.

Compared to the simpler SA-600 model, it has been enhanced with a significant innovation – an automatic pellet burner. It controls its own operation, ignites automatically, dispenses pellets, and regulates the temperature. As a result, it requires less operator involvement, and the device can function in a nearly autonomous mode for a certain period.

The dryer is based on a simple yet effective mechanism – the material moves through a system of pipelines with hot air flowing through them. Under the influence of appropriately selected temperature, moisture from the surface of the material quickly evaporates, while the moisture from inside gradually moves to the outside. This process ensures safe and efficient drying. A masonry furnace or a biomass burner can serve as the heat source, allowing you to maintain the optimal working temperature. The device works perfectly with pellet production lines.

When combined with a pellet production line, it creates a complete set for manufacturers of this type of fuel. For example, it can be integrated with the LDG series line.

It is possible to test this machine on your raw material at our warehouse!

Video: Pellet production from pine sawdust | 25 kW Line + SA-600 Dryer

Video: LDG-4000 KOMBI pellet production line + SA-600 Aerodynamic Dryer | Performance - 500 kg/h.

Video: LDG-4000 MAX Pellet Production Line + SA-600 Dryer

Set Contents

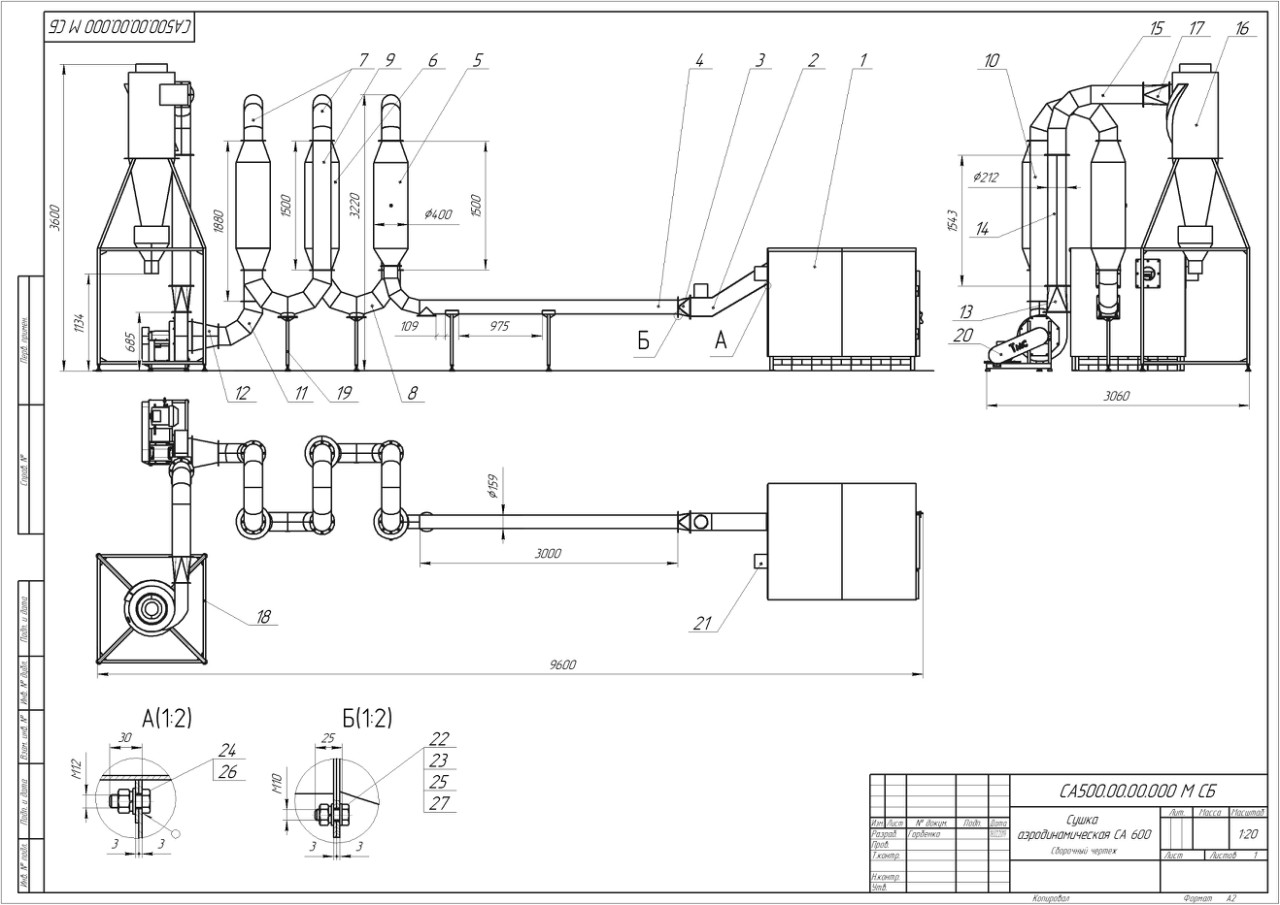

The SA-600 aerodynamic dryer consists of the following components:

1. Furnace (masonry, made of 700 fireclay bricks)

3. Pipeline system

4. Anti-dust centrifugal fan

5. Cyclone

6. Control panel

7. Domna 350 Burner with auger and control panel

Bricks for the furnace are not included in the set!

The components are delivered separately for on-site assembly.

Our aerodynamic dryers are delivered disassembled, which facilitates transport and allows optimal use of loading space. Assembling the device is a process requiring precision and experience. Therefore, we recommend contacting our customer service specialist before starting installation. Professional technical support will help avoid potential problems and ensure correct commissioning of the dryer, which directly affects its performance and long life.

Automatic pellet burners (DOMNA-250 and DOMNA-350) are also compatible with our SA-400 and SA-600 aerodynamic dryers. To install such a burner, you simply need to replace the doors in the existing furnace.

Video: LDG-4000 KOMBI pellet production line + SA-600 Aerodynamic Dryer | Performance - 500 kg/h.

Advantages of the SA-600 PRO sawdust dryer

- Versatility – allows drying of various plant materials, including sawdust (from coniferous and deciduous trees), wood chips, straw, and grain residues

- High efficiency – drying up to 600 kg/h, meeting the requirements of industrial plants

- Effective drying – fast, precise, uniform removal of moisture from light and shredded raw materials (from 60% to 6–12%), which significantly shortens the material preparation time for further processing steps

- Easy operation – after initial setup, operation is largely automatic; the control board and safety systems enable accurate monitoring of the drying process

- Energy efficiency – the dryer consumes little energy thanks to its connection with the furnace, which reduces costs

Free: laser digital thermometer and lubricating grease gun

156,2 kB

Application of the SA-600 PRO pipe dryer for sawdust

SA-600 PRO Aerodynamic Sawdust Dryer works well wherever fast and efficient processing of plant residues is required. The machine is used in the wood and energy sectors, as well as in farms and pellet production plants.

Technical parameters of the SA-600 PRO aerodynamic sawdust dryer

- Pipeline length – 25m

- The calibrator hopper can hold 1 m3 of sawdust

- 3 expansions;

- Fan power – 5.5 kW

- Output – 600 kg/h

- "Cyclone" system

- Raw material initial moisture up to 60%

- Output up to 600 kg/h

- Length 9600 mm. x Height 3600 mm. x Width 3060 mm, weight: 1000 kg.

- Complete line with dryer: L.13000 mm. x H. 3500 mm. x W. 4000 mm, weight: 2300 kg.

Processed raw materials:

- sawdust;

- wood chips;

- straw;

- cereal waste and many other materials.

Stages of sawdust dryer operation:

- The feed tank is filled with 1 m³ of raw material, which is screened with a vibrating mesh above the tank.

- At the same time, hot air – often called the "drying agent" – is forced into the pipeline.

- Together with the drying agent, the raw material is transported through the pipeline.

- Due to the high temperature, moisture from the surface of the raw material evaporates, and internal moisture moves towards the surface.

- This process and properly selected temperature prevent the particles from igniting.

Do you need more information about this device?

Contact us – we will advise you on the best solution!

Contact us