Calibrator-feeder KPS-600

- Product Code: KPS-600

Description

Calibrator – KPS-600 Screw Feeder is a reliable device designed for effective screening of bulk materials. Equipped with a sifter with a vibrating screen, KPS-600 enables effective removal of bark, pieces of wood, branches, and other contaminants.

KPS-600 allows uninterrupted and precise dosing of raw materials to a pellet mill, briquette press, or other processing machine. The model features a hopper with a capacity of 1 m³—ensuring an adequate material reserve.

Feed rate control is provided via a frequency converter (optional).

The sifter screen is driven by a vibration motor, enabling effective calibration of the material before further production stages.

KPS-600 can successfully operate as part of a pellet or feed production line, and also serve as a feeder in the SA-600 aerodynamic drying complex.

You can test this machine with your material at our warehouse!

Main advantages of the KPS-600 Calibrator–Feeder

- Effective separation of contaminants thanks to the vibrating sifter.

- Possibility to feed and calibrate the material simultaneously.

- Large hopper capacity (1 m³) reduces loading frequency.

- Two independent drives (screw and agitator) ensure smooth and efficient operation.

- Adjustable feed rate thanks to the option of using a frequency converter.

- Robust design suited for industrial environments.

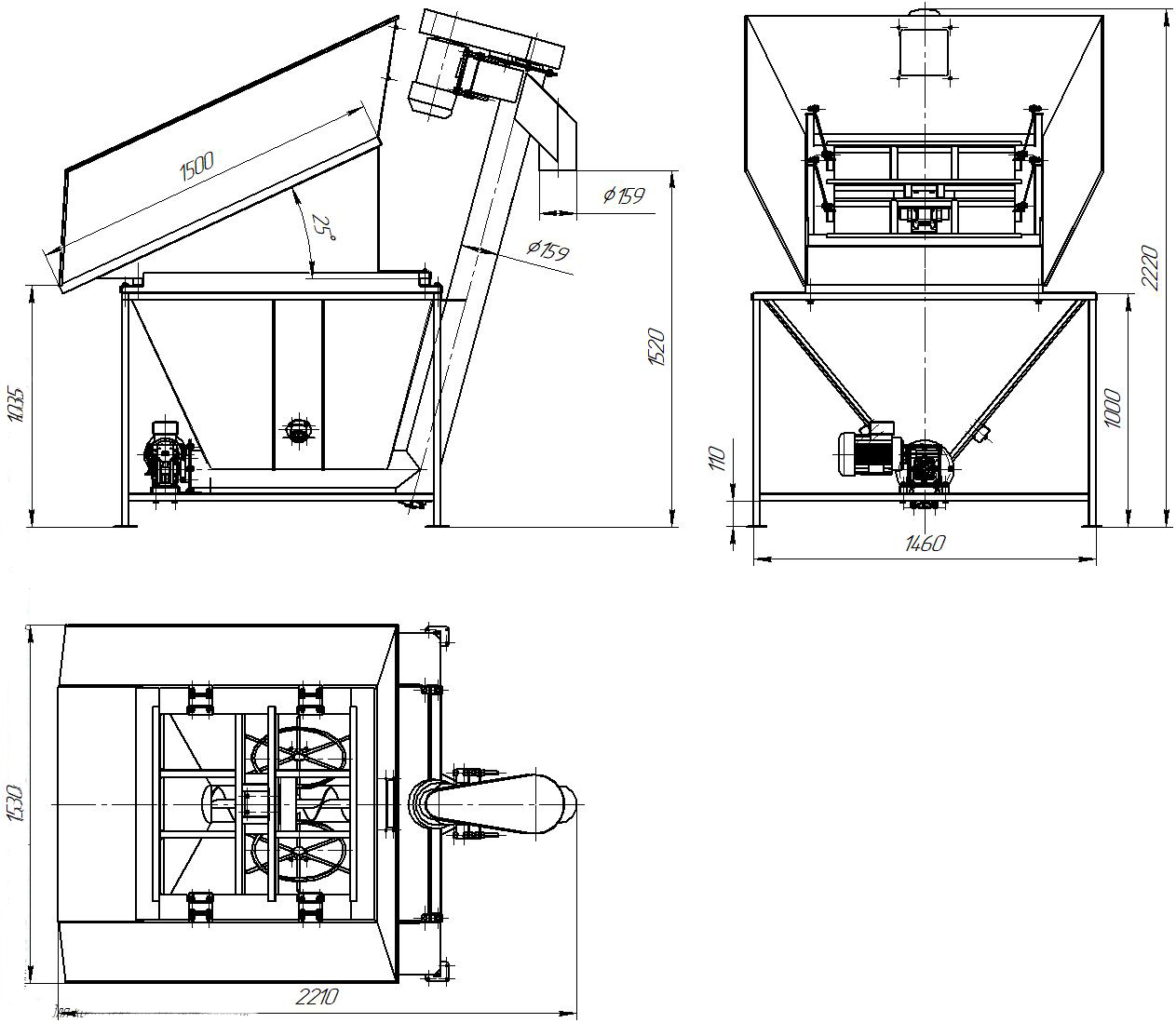

Technical drawing:

Applications of the KPS-600 Calibrator–Feeder

The KPS-600 Calibrator–Feeder is an excellent choice for pellet and feed production lines, as a raw material feeder for pellet mills, briquette presses or mills, and for use with aerodynamic dryers.

KPS-600 can be used in the wood industry, agriculture and in biomass processing plants, where it can perform preliminary calibration of the material before granulation and further processing.

All our screw feeders are equipped with two neodymium magnets that remove metal contaminants from the material.

Technical specifications:

- Lower screw drive power: 2.2 kW, 380–400 V

- Feeder screw drive power: 1.5 kW, 380–400 V

- Vibration motor: 90 W

- Hopper capacity: 0.6 m³

- Conveyor type: screw

- Conveying path type: vertical, enclosed

- Weight: 340 kg

Overall dimensions:

- Length: 2200 mm

- Width: 1500 mm

- Height: 2200 mm

Need more information about this device?

Contact us—we will recommend the best solution for you!

Contact us