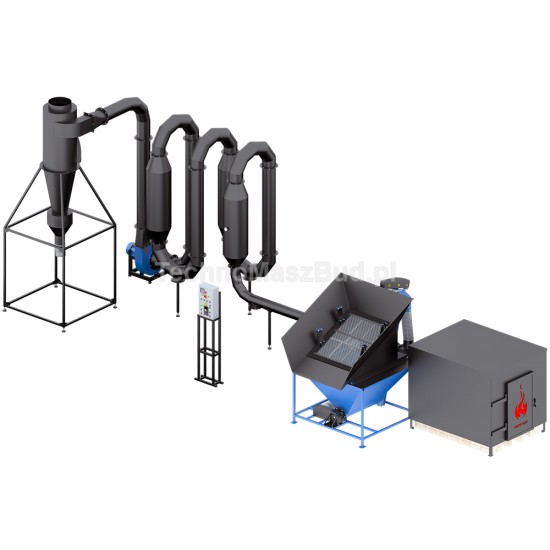

Aerodynamic Sawdust Dryer SA-600

- Product Code: SA-600

Description

SA-600 Sawdust Dryer is a device for drying materials such as sawdust, wood chips, straw, and grain waste. It is used to prepare material before pelleting, granulating or briquetting.

Tube dryer for sawdust and other biomass uses a simple operating mechanism: the material is dried in an aerodynamic pipeline, where a stream of hot air circulates. Thanks to the high temperature, moisture from the surface of the raw material evaporates, and the internal moisture moves to the surface – thus reducing the risk of ignition.

The heat source is a connected wood-burning stove or optionally a pellet burner (must be purchased separately), such as the DOMNA-350 model.

This machine is an ideal supplement to the LDG-4000 granulation line KOMBI as well as LDG-3000 PRO.

It is possible to test this machine with your raw material in our warehouse!

Video: Production of pine sawdust pellets | 25 kW line + SA-600 Dryer

Video: Pellet Production Line LDG-4000 KOMBI + SA-600 Aerodynamic Dryer | Output - 500 kg/h.

Video: Pellet Production Line LDG-4000 MAX + SA-600 Dryer

Kit contents

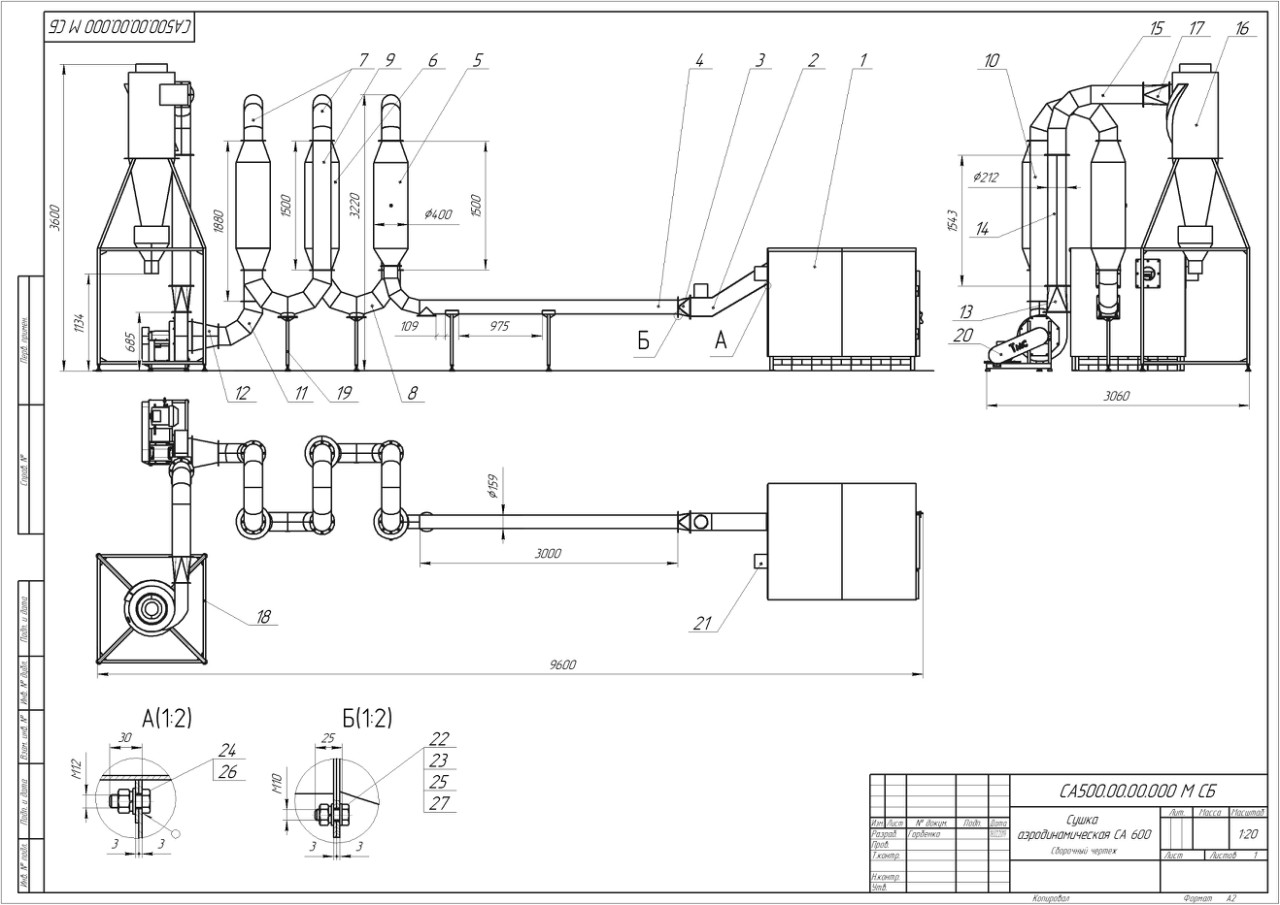

The aerodynamic SA-600 dryer consists of the following parts:

1. Furnace (built from 650 fireclay bricks)

3. Pipeline system

4. Anti-dust centrifugal fan

5. Cyclone

6. Control panel

Components are delivered separately, for on-site assembly.

Bricks for the furnace are not included in the kit!

Video: Pellet Production Line LDG-4000 KOMBI + SA-600 Aerodynamic Dryer | Output - 500 kg/h.

Advantages of the SA-600 sawdust dryer

- Versatility – allows drying of various plant materials, including sawdust (coniferous and deciduous), chips, straw, and grain residues

- High efficiency – drying up to 600 kg/h, which meets the requirements of industrial plants

- Efficient drying – fast, precise, uniformmoisture removal from light and shredded raw materials (from 60% down to 6–12%), whichsignificantly shortens the material preparation time for subsequent processing steps

- Easy operation – once set up, operation is largely automatic; the control panel and safety systems allow precise process monitoring

- Energy efficiency – the dryer has low energy consumption due to integration with a furnace, which reduces operating costs

Free bonus: digital laser thermometer and greasing pump

156,2 kB

Applications of the SA-600 tube sawdust dryer

The SA-600 aerodynamic sawdust dryer can be used wherever efficient and effective processing of plant residues is required. The machine can be used in the wood and energy sectors, as well as agricultural holdings and pellet manufacturing companies.

Technical parameters of the aerodynamic SA-600 sawdust dryer

- pipeline length – 25m

- the feeder tank can hold 1 m³ of sawdust

- 3 expansions

- fan power – 5.5 kW

- capacity – 600 kg/h

- initial moisture content up to 60%

- Capacity up to 600 kg/h

- L. 9600 mm x H. 3600 mm x W. 3060 mm, weight: 1000 kg

- The entire line with the dryer: L.13000 mm x H. 3500 mm x W. 4000 mm, weight: 2300 kg

Work stages of the sawdust dryer:

- Raw material (1 m³) is poured into the feed tank, which is screened by a vibrating mesh above the tank

- At the same time, hot air, often called the "drying agent", is injected into the pipeline

- Together with the drying agent, the raw material is transported through the pipeline

- Due to high temperature, moisture from the surface of the raw material evaporates, and the internal moisture migrates to the surface

- This process and the properly selected temperature prevent particle ignition

Processed raw materials:

- sawdust;

- wood chips;

- straw;

- grain waste and many other materials.

Need more information about this machine?

Contact us – we'll recommend the best solution for you!

Contact us