Granulation Line LDG-3000 (KOMBI) PRO

Available Options

- Product Code: LDG-3000-KOMBI-PRO

Description

After many intensive tests, implementations, and improvements, we are proud to present the LDG-3000 KOMBI PRO production line – a modern solution for pellet production with a capacity of up to 500 kg/h, depending on the type of raw material.

Thanks to the use of a more powerful PRIME-300 PRO granulator compared to the LDG-3000 KOMBI line, the LDG-3000 KOMBI PRO line achieves even greater operating stability and higher efficiency, while maintaining simple operation and versatility in processing various raw materials.

LDG-3000 (KOMBI) PRO granulation line is a modern and versatile technological line designed for the production of heating pellets, granulated animal feed, and plastic granules.

YOU CAN TEST THIS MACHINE WITH YOUR RAW MATERIAL AT OUR WAREHOUSE!

The device was designed with farms, feed mills, sawmills and carpentry shops in mind, which are looking for efficient and economical technological solutions dedicated to biomass processing, agricultural waste, and wood waste.

The high efficiency of the LDG-3000 (KOMBI) PRO is ensured by the collaboration of key components – auger feeder, humidification system, PRIME-300 PRO granulator, cooler, extraction system and control panel with inverter.

The line is distinguished by stable operation, high efficiency, and application versatility.

Video: Pelletizing pine sawdust | Capacity up to 400 kg/h:

The central element of this line is the PRIME 300 PRO pelletizer, a crucial component of the entire production process. Equipped with an inverter, it not only ensures high efficiency but also safety and precise engine operation. The 300 mm diameter die can be customized to the client’s preferences, with hole options of 6 mm and 8 mm, allowing the production of pellets with different hardness.

For your convenience, we can not only select the line tailored to your needs but also assist with installation, commissioning, and achieving the desired result!

Construction and Components:

- PS-200 PRO Auger Feeder – equipped with an inverter for smooth feed rate adjustment and neodymium magnets eliminating metal contaminants.

- Humidification system (0.37 kW) – 100 l tank, valve, pump, and nozzle provide precise moisture dosing during granulation.

- PRIME-300 PRO Pelletizer (30 kW) – granulator with a capacity up to 500 kg/h (pellets) and up to 700 kg/h (feed), with a Ø 300 mm die and moving rollers; ensures high durability and process reliability.

- KC-200 Calibrator-Cooler (0.12 kW) – responsible for cooling finished pellets and removing dust and crumbs.

- SO-2 Extraction System (1.5 kW) – ensures air circulation and dust collection into collecting bags, improving cleanliness and work safety.

- Control panel with inverter – compact, with ammeters and thermal protections; enables full process control and adjustment of work parameters.

- 30 kW inverter - provides smooth start-up, rotational speed regulation, overload protection, and energy savings, thereby increasing safety, durability, and operational efficiency.

(The belt conveyor and connection cables are not included in the set)

Video: Output measurement on oak sawdust | LDG-3000 KOMBI pellet line:

LDG-3000 KOMBI PRO pellet production line efficiency:

- wood waste – 500 kg/h; (output depends on the hardness and type of input);

- straw – up to 500 kg/h;

- feed – up to 700 kg/h;

The most important is fulfilling the requirement of the fraction and the moisture level of the processed raw materials.

What type of raw material can be used to produce pellets?

- Sawdust from hard and softwood species;

- Waste from sunflower, corn, grain cleaning, straw, branches, seed husks;

- Plastic production waste.

What type of raw material can be used to produce feed?

- Grain, cereals, grist, hay, feed mixture.

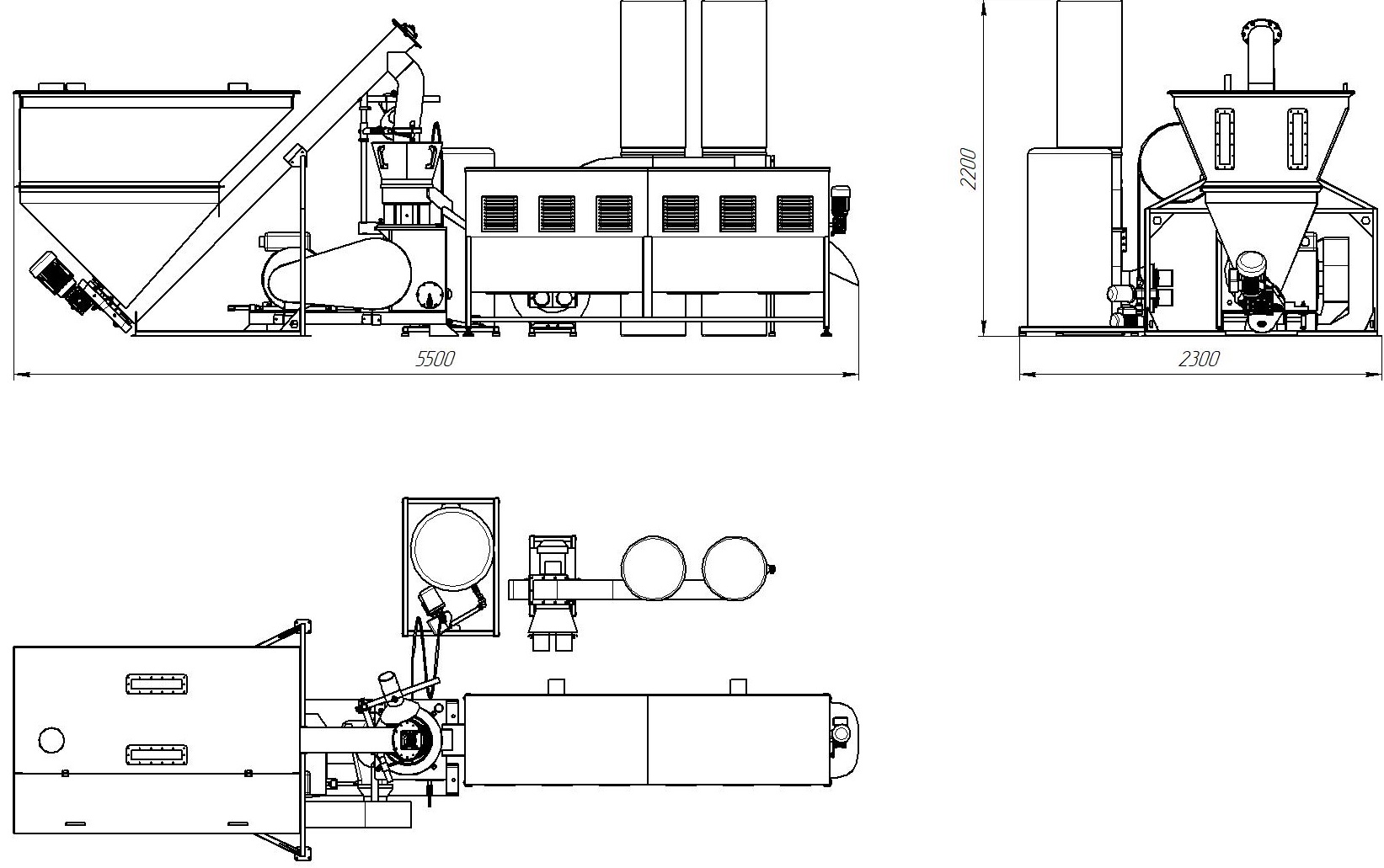

Technical drawing:

Advantages of LDG-3000 (KOMBI) PRO line

- High efficiency – up to 700 kg/h of feed and around 500 kg/h of pellets.

- Modern PRIME-300 PRO granulator – increased power and Ø 300 mm die allow operation with a wide range of raw materials.

- Compact and integrated design – all components work in one line, which simplifies assembly and use.

- Wide raw material compatibility – possibility to process sawdust, wood chips, straw, husks, grains, agricultural waste, and plastics.

- Energy efficiency – optimized power consumption (32 kW) with high output.

- Work safety – thanks to extraction systems, inverter, and thermal protections.

- Economy and ecology – minimizing waste, the possibility of re-granulating dust, and using a wide raw material base.

The set includes an inverter for the 30 kW pelletizer motor, which has several practical justifications:

- Softstart (gentle start-up):

- During startup, the motor draws a very large starting current (even 6–8 times nominal).

- The inverter limits this current, which protects the electrical installation, fuses, and the motor itself from overload.

- Reduces the risk of sudden mechanical impacts on gears and couplings.

- Speed regulation:

- Ability to adjust rotational speed according to the type of raw material

- Work optimization – you can find such RPM at which the extruder has maximum efficiency and minimum energy consumption.

- Easier start-up under heavy load – first low RPM, then gradual increase.

- Operation safety and control:

- The inverter monitors the current and load of the motor – it can stop the machine in case of overload.

- Allows the connection of protections, automation, and line control.

- Economy and durability:

- Less energy consumption compared to full-speed operation with light load.

- Extended lifespan of the motor, transmission, and drive elements.

The 30 kW inverter in the pelletizer is an investment in safety, operational flexibility, and lower operating costs.

Technical support and training

With delivery, we offer comprehensive support: assembly, commissioning, configuration, and staff training (assembly and commissioning are extra paid services). Thanks to this, the user receives assurance of correct operation and maximum efficiency in daily use.

Application

LDG-3000 KOMBI PRO granulation line is a comprehensive solution tailored to the needs of biomass processors.

The device will prove itself both in enterprises engaged strictly in the production of heating pellets and in farms or animal breeding operations – as a machine for pressing granulated feed.

Need more information about this equipment?

Contact us – we’ll advise you on the best solution for you!

Contact us