Granulation Line LDG-3000 (DUO) PRO

Available Options

- Product Code: LDG-3000-DUO-PRO

Description

LDG-3000 DUO Pellet Production Line PRO is an advanced solution designed for the production of high-quality feed pellets. With the use of two PRIME-300 PRO pellet mills, the line achieves a capacity of up to 1000 kg/h for wood pellets and up to 1400 kg/h for feed pellets. Each pellet mill is equipped with a 30 kW motor, a 300 mm diameter die, and 178 mm diameter rotating rollers, ensuring efficient processing of various raw materials. Additionally, the line is equipped with a humidification system, calibrator-cooler, and a closed extraction system, guaranteeing high quality of the final product.

IT IS POSSIBLE TO TEST THIS MACHINE WITH YOUR MATERIAL IN OUR WAREHOUSE!

One of the key advantages of the LDG-3000 DUO PRO line is its ability to operate continuously even during service or unforeseen failures. Thanks to the use of two PRIME-300 PRO pellet mills, the line can continue production when one of the mills is shut down for maintenance or repair. This solution ensures the continuity of the technological process, minimizes downtime, and significantly increases production efficiency and reliability, guaranteeing uninterrupted operation of the entire system.

Video: Complete LDG-3000 DUO Pellet Line | Production from oak sawdust :

Video: LDG-3000 DUO Pellet Line | Production from pine sawdust:

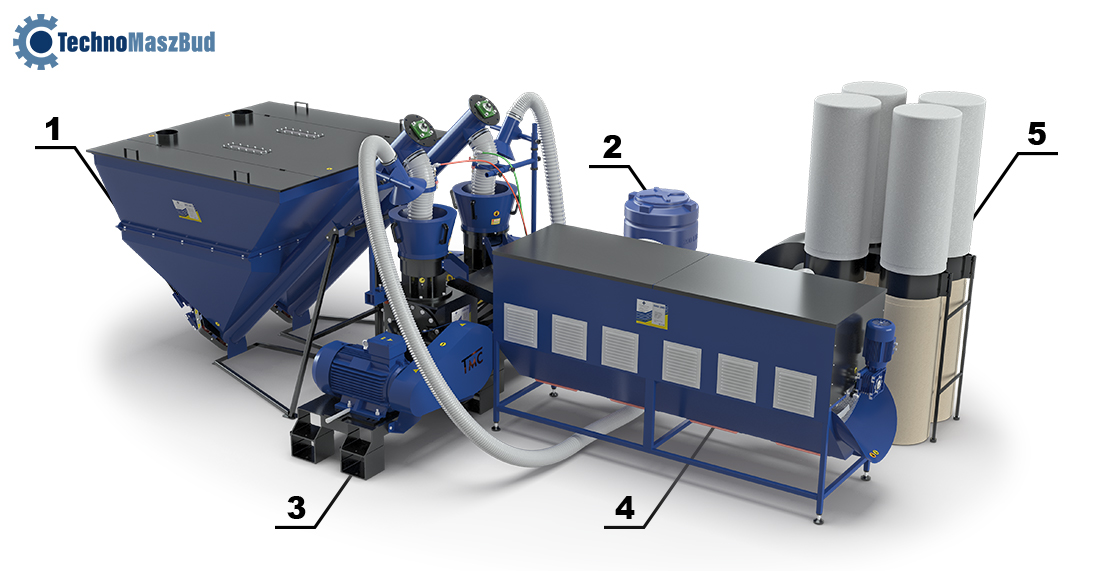

The LDG-3000 DUO PRO granulation line consists of:

1. Screw feeder PS-200 DUO PRO:

The feeder is designed for collecting raw material and evenly supplying biomass to the pellet mill. This unit has smooth adjustment of feed rate by frequency converter. Total power consumption – 3 kW. Hopper capacity – 2 m³ (two cubic meters).

2. Humidification system:

Used to ensure adequate moisture content of the raw material. The system consists of the following elements: valve, pump, 100-liter water tank, and nozzle. Humidification is done with the required, precisely measured amount of water during granulation by connecting the system to the stand above the working part. Power consumption 0.37 kW.

3. Reliable PRIME-300 PRO pellet mills:

Two universal PRIME-300 granulators process various types of material, achieving an actual capacity of up to 1000 kg/h for sawdust pellets and up to 1400 kg/h for feed pellets.

4. Calibrator – cooler for granules/pellets KC-300:

Hot pellets discharged from the granulator fall onto the calibration sieve of the drum. As the drum rotates, the pellet spreads in a thin layer on the surface. At the same time, an airstream generated by a fan passes through the cooling chambers. It cools the pellets, reducing their moisture via the top side port, while small gravel and dust are routed through two lower ports, via the cyclone, to bags.

5. Closed extraction system SO-4:

The closed extraction system collects excess dust and raw materials from the cooling and pellet sorting system and collects them in bags, while also filtering the air of dust via two upper filter bags. The heart of the system is a high-performance fan that creates the necessary negative pressure in the circuit, allowing effective extraction of small particles and dust.

6. Control cabinet (control panel):

The control cabinet houses electric remote and automatic control devices for the complex’s mechanisms and electric drives, installed in the control cabinet. The compact dimensions and built-in automation cooling system make the control panel reliable and convenient for installation near the production line.

7. 30 kW frequency inverters (2 pcs):

The frequency inverters provide soft start, speed adjustment, overload protection, and energy savings, thus increasing the safety, durability, and efficiency of the machine's operation.

Cables for connecting the line are not included!

Video: LDG-3000 DUO Pellet Production Line + SA-800 Dryer | Pellet production at sawmill:

Video: Complete pellet line with capacity up to 800 kg/h | Production from pine sawdust:

The set includes frequency inverters for the 30 kW pellet mill drive motors, which have several practical purposes:

- Soft start:

- The motor at startup draws a very high starting current (even 6–8 times more than nominal).

- The frequency inverter limits this current, protecting the electric installation, fuses, and the motor from overload.

- It reduces the risk of sudden mechanical shocks in gearboxes and couplings.

- Speed control:

- Ability to adjust the rotational speed to the type of raw material.

- Optimized operation – you can find the optimum speed for maximum extruder efficiency and minimum energy consumption.

- Easier startup under heavy load – start at low speed, then gradually increase.

- Protection and process control:

- The frequency inverter monitors the motor current and load – it can stop the machine in case of overload.

- It allows for connecting protections, automation, and line control.

- Economy and durability:

- Lower energy consumption compared to operating at full speed with light load.

- Extended service life of the motor, gearboxes, and drive components.

A 30 kW frequency inverter in a pellet mill is an investment in safety, work flexibility, and lower operating costs.

LDG-3000 DUO pellet production line performance:

- wood waste – 1000 kg/h (productivity depends on the type and properties of the raw material used);

- straw – up to 1000 kg/h;

- feed – up to 1400 kg/h.

Achieving optimal pellet production efficiency largely depends on maintaining appropriate parameters of the processed raw materials. Careful selection and proper preparation of the input material are key to stable operation of the production line and obtaining a high-quality finished product.

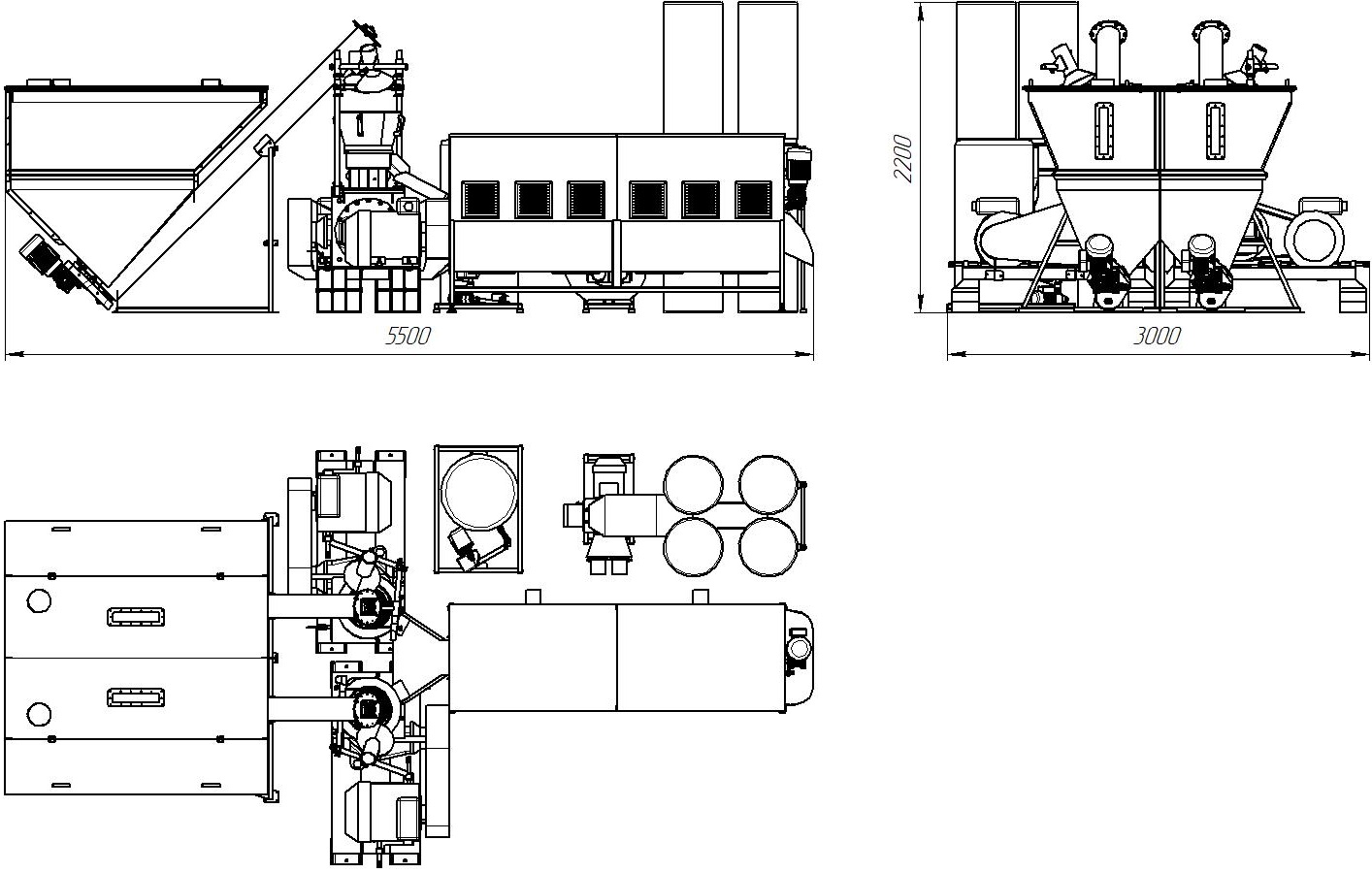

Technical drawing:

LDG-3000 DUO PRO line configurations

LDG-3000 DUO PRO line is available in various configurations that can be tailored to individual production needs. The offered options include, among others, additional belt conveyors, shredders, aerodynamic dryers, and calibrators, allowing for full automation of pellet and feed granulation production processes.

Technical support and training

With delivery, we provide professional technical support, assistance with installation and commissioning, and training for personnel. This gives the user confidence in proper equipment operation and maximum efficiency in daily work.

Applications

LDG-3000 DUO Pellet Line PRO is used in the feed, agricultural, and fuel pellet industries. It is ideal for medium-sized production facilities that require high productivity and flexibility in raw material selection.

Video: Complete LDG-3000 (DUO) Pellet Production Line | up to 800 kg/h:

Video: Complete LDG-3000 DUO Pellet Production Line | Capacity up to 800 kg/h:

Do you need more information about this device?

Contact us – we’ll advise the best solution for you!

Contact us