Granulation Line LDG-4000 (DUO)

Available Options

- Product Code: LDG-4000-DUO

Description

LDG‑4000 DUO Pellet Production Line is an advanced technological solution featuring a double system of PRIME‑400 pellet mills, designed for maximum efficiency and reliability in pellet production (2–8 mm). The twin-pellet-mill design enables continuous high-efficiency production, even during maintenance of one of the machines. The same principle has also been used to connect the PS-200 screw feeders, ensuring uniform and stable material feed to the granulation process.

The main advantage of such a solution is the possibility of continuous line operation even during servicing or unexpected failure. If necessary, one pellet mill can be maintained or repaired while the other continues to operate, ensuring uninterrupted production.

YOU CAN TEST THIS MACHINE ON YOUR MATERIAL AT OUR WAREHOUSE!

This type of line performs excellently when working with sawdust, wood chips, wood dust, straw, sunflower waste, or feeds.

This equipment differs from the LDG-3000 DUO pelletizing line series primarily by the use of more powerful pellet mills. The granulation line can be used for both pellet production and compound feed production—for your own needs or for commercial activities.

For your convenience, we offer not only selection of the proper line for your requirements, but also assistance with installation, commissioning, and achieving your expected results!

Video: Complete LDG-3000 DUO pellet line | Oak sawdust processing :

Video: LDG-3000 DUO pellet line | Pellets production from pine sawdust:

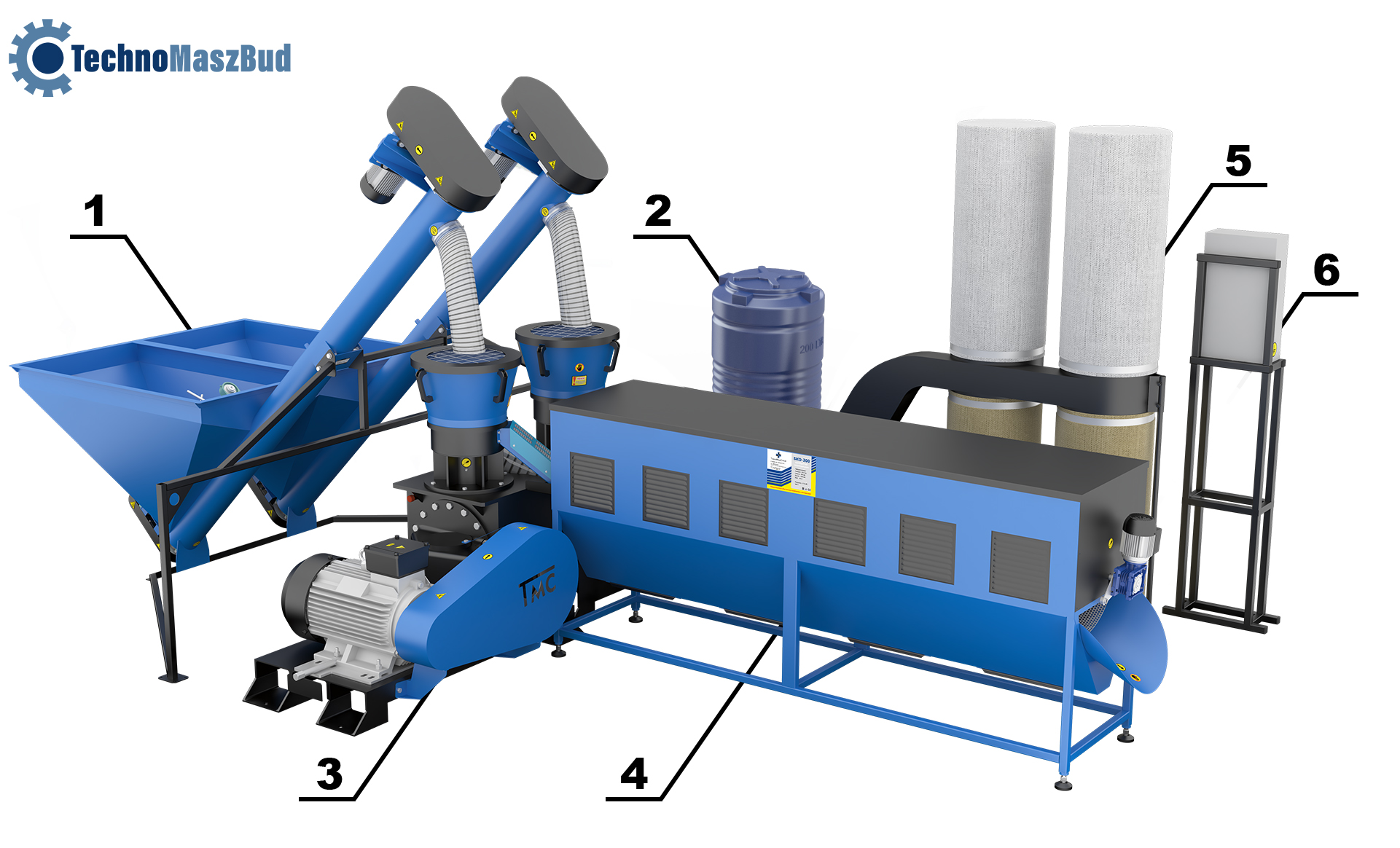

The LDG-4000 DUO line comprises:

The feeder is designed for collecting raw material and feeding it evenly into the pellet mill. Equipped with a frequency inverter, it allows for smooth regulation of the feed rate, ensuring stable and efficient operation of the entire system. Power consumption: 1.5 kW.

2. Humidification system

The system’s purpose is to maintain optimal raw material humidity during the granulation process. It consists of a valve, pump, a 200-liter water tank, and a spray nozzle. The system is connected to a stand above the working area, allowing for precise dosing of the required amount of water during operation. Power consumption: 0.37 kW.

Reliable and universal pellet mills adapted for use with various types of biomass. The total actual capacity of the devices is up to 1300 kg/h when producing pellets from sawdust and up to 1400 kg/h when granulating feeds. The PRIME-400 design provides high durability and simple operation. Power consumption: 74 kW.

4. KC-200 Granulate/Pellet Calibrator Cooler

Hot granules leaving the pellet mill land on the rotary calibration sieve, which distributes the material evenly in a thin layer over the drum surface. Simultaneously, the cooling chambers are ventilated by a fan, reducing the temperature and humidity of the pellets. Fine dust and contaminants are removed by a cyclone system into bags. Power consumption: 0.12 kW.

5. SO-4 Closed Extraction System

The extraction system removes excess dust and fine fractions from the cooling and sorting unit. The air is cleaned through four upper filter bags, and purified material is collected into collection bags. A high-performance fan ensures proper pressure and effective operation of the system. Power consumption: 3 kW.

6. Control cabinet (control panel)

The control cabinet provides remote operation and protection of all the line’s electrical components. It is fitted with ammeters, thermal protections, and an automation cooling system. Its compact design allows easy installation near the production line and ensures reliability in everyday use.

Actual output of the LDG-4000 DUO pellet production line

(depending on the type of raw material):

- wood waste – up to1300 kg/h

- straw – up to1100 kg/h

- feed – up to1400 kg/h

- sunflower husk – up to1100 kg/h

Achieving the desired output largely depends on meeting the requirements for fraction and humidity of the processed raw materials.

Video: LDG-3000 DUO pellet production line + SA-800 dryer | Pellets production at a sawmill:

Video: Complete pellet line with up to 800 kg/h output | Production from pine sawdust:

Types of LDG‑4000 DUO lines:

LDG-4000 DUO pellet line is available in various configurations, differing in the level of automation and additional components supporting the granulation process. The customer can choose the base version or one extended with extraction systems, conveyors, shredders, or dryers, depending on production needs and scale..

The LDG-4000 DUO pellet production line can be additionally equipped with:

PK-2 conveyor-calibrator: main purpose is feeding and calibration of raw materials;

PT-250 belt conveyor: main purpose is feeding and cooling of raw material;

PT-500 belt conveyor: main purpose is feeding and cooling of raw material;

RD-500 shredder: main purpose is grinding raw materials (straw, hay, chips, etc.) to required fraction;

KPS-400 calibrator-feeder: main purpose is calibrating and uniform feeding of raw material;

SA-600 aerodynamic dryer with calibrator: main purpose is calibrating and drying raw materials.

Example sets with the LDG-4000 DUO line:

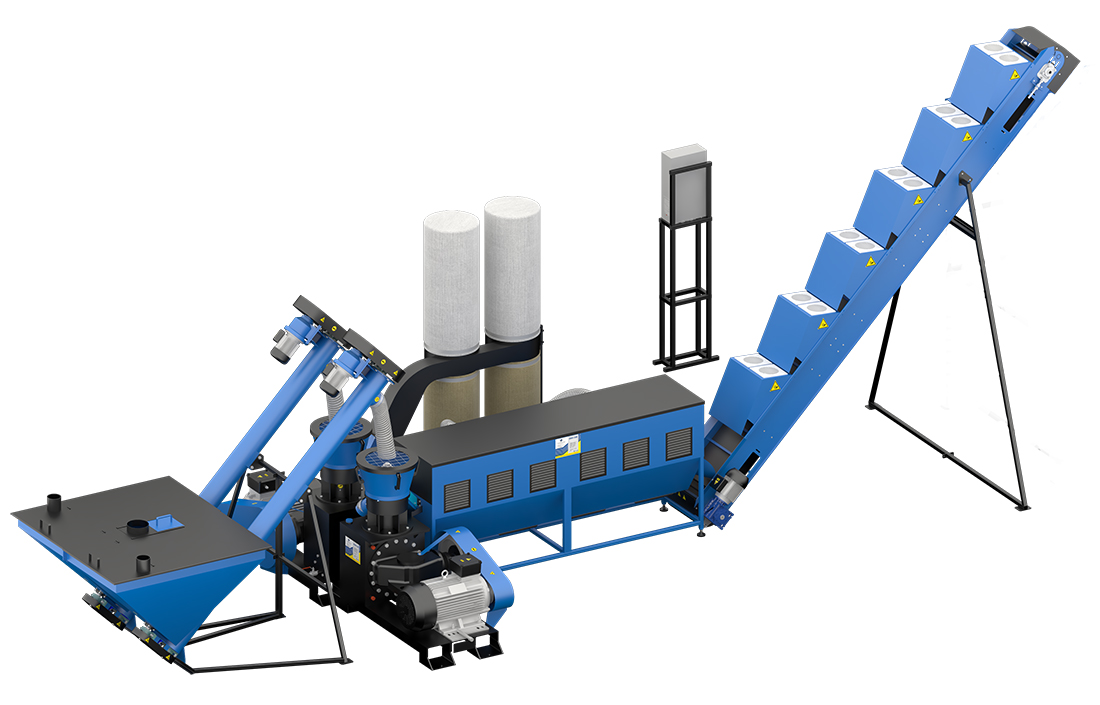

1. LDG-4000 DUO Line + PT-500 Belt Conveyor with Fans

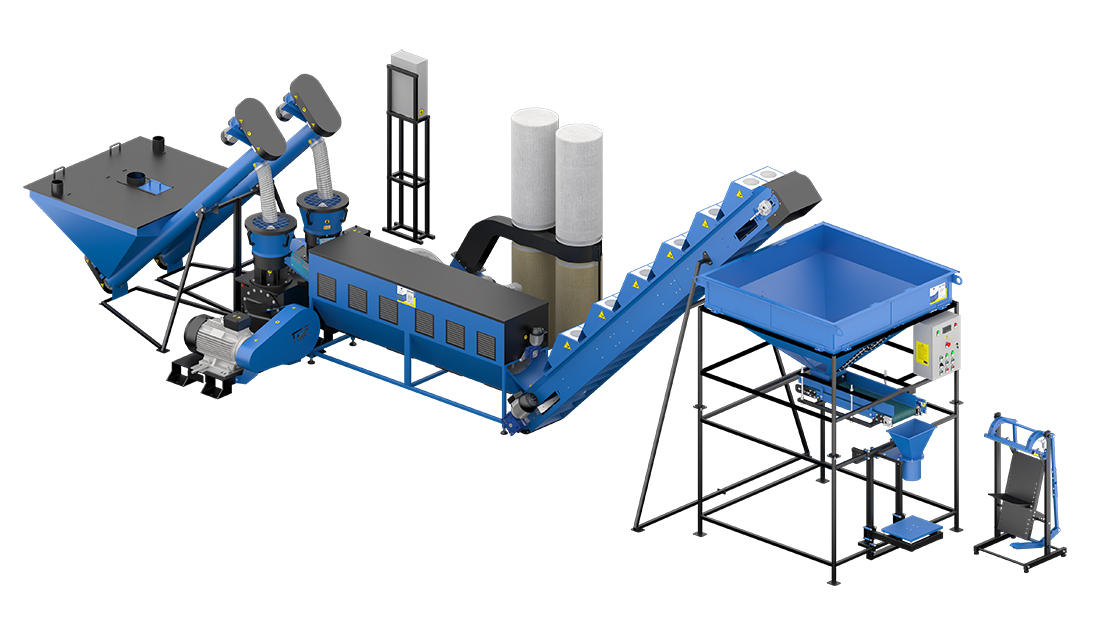

2. LDG-4000 DUO Line + LCP-600 pellet cooling and packing line

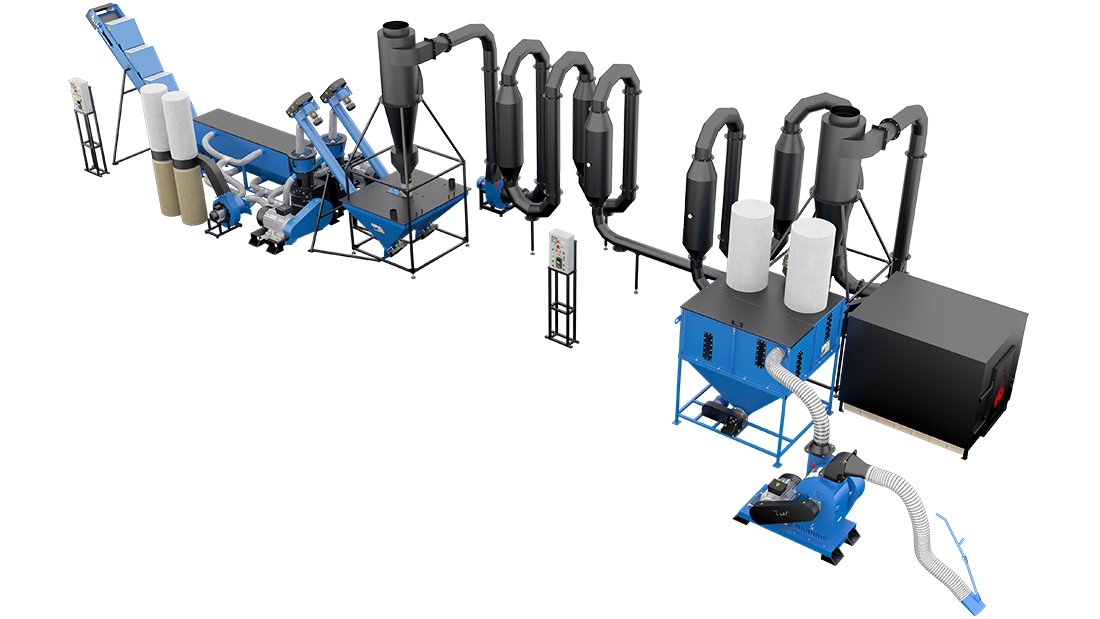

3. LDG-4000 DUO Line + PT-1000 Belt Conveyor with Fans + SA-800 Aerodynamic Sawdust Dryer + MB-1000 Hammer Mill

If your dream set is not listed here, contact us or use our configurator!

Main advantages of the LDG-4000 DUO pellet production line:

- Dual pellet mill – uninterrupted pellet production even during maintenance

- High output: up to 1,400 kg/h of feed and up to 900 kg/h of wood pellets

- Raw material flexibility – pellets from wood, biomass, straw, feed, and agricultural waste

- Possible system expansion with additional modules and equipment

- Control panel with intuitive operation and a full safety system

- Modular and compact design, minimizing space requirements

Video: Complete LDG-3000 (DUO) pellet production line | up to 800 kg/h:

Video: Complete LDG-3000 DUO pellet production line | Output up to 800 kg/h:

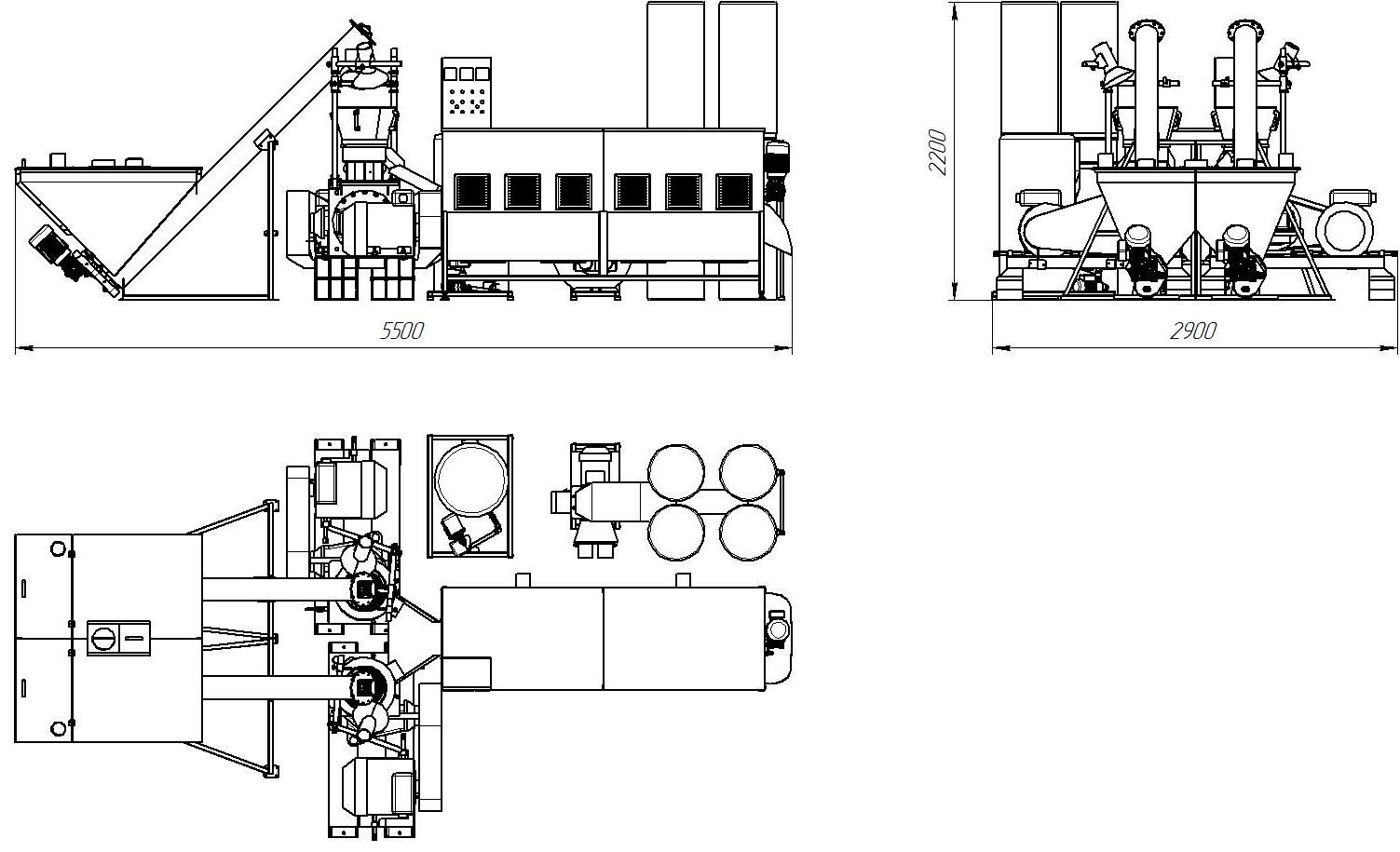

Technical drawing:

Technical support and training

With delivery, we provide professional technical support, help with installation and commissioning, as well as personnel training. This way, the user is assured of correct operation and maximum efficiency in everyday use.

Applications

LDG‑4000 DUO line is ideal wherever high and stable production of fuel pellets or feed is needed—at sawmills, on farms, at recycling points, and in small energy and feed plants.

Pellet production lines from the LDG series offer maximum efficiency, flexibility, and savings—a reliable solution for companies that require uninterrupted operation and high pellet quality.

Need more information about this device?

Contact us – we will advise you on the best solution!

Contact us