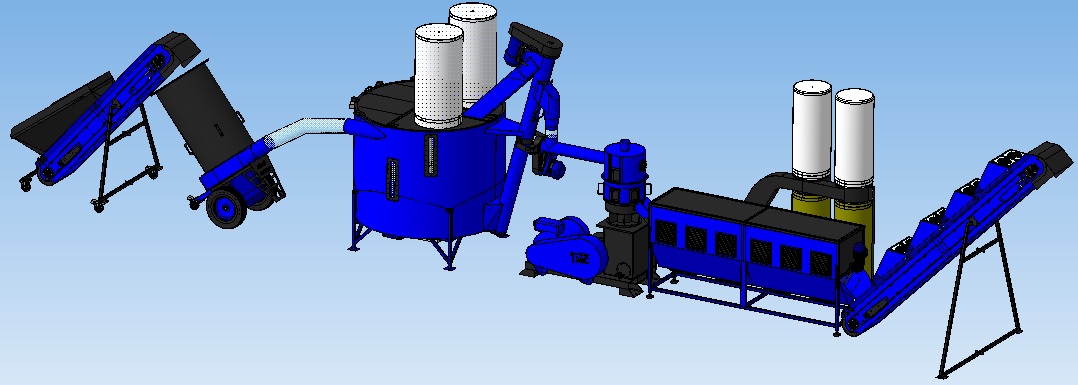

Granulation Line LDG-4000 (MAX+)

Available Options

- Product Code: LDG-4000_MAX+

Description

LDG-4000 MAX+ Pellet Production Line is a modern and efficient technological solution that enables granulation of various raw materials. The machine is designed to produce pellets with a diameter from 2 mm to 8 mm, which allows for the production of both wood fuel pellets and animal compound feed. The line’s capacity reaches up to 500 kg/h for feed production and up to 450 kg/h for wood pellets, making it perfectly suitable for agricultural, carpentry, sawmill, and energy facilities.

IT IS POSSIBLE TO TEST THIS MACHINE ON YOUR MATERIAL AT OUR WAREHOUSE!

The LDG-4000 MAX+ pellet production line is an extended version of the LDG-4000 line manufactured by TechnoMaszBud.

Compared to the KOMBI/MAX model, this set is equipped with a PS-1500 feeder with a capacity of 1.5 m³, which supplies raw material evenly to the PRIME-400 pelletizer, ensuring stable and efficient operation of the entire system. The PS-1500 also acts as a cyclone with built-in dust bags. The line allows for the connection of a shredder and hammer mill.

Video: Production of pellets from pine shavings | LDG-4000 (MAX+) pellet production line

The LDG-4000 MAX+ line includes:

This unit consumes 2.6 kW of electricity and serves as a cyclone. The main function of the PS-1500 is to feed the raw material to the pelletizer. Hopper capacity: 1.5 m³.

2. Moisturizing system:

The main components are a valve, pump, 100-liter water tank, and nozzle. The system is connected to a stand above the working section, allowing precise addition of the required amount of moisture during granulation. Power consumption: 0.37 kW.

3. Reliable PRIME-400 pelletizer:

The PRIME-400 granulator easily processes various raw materials, achieving capacity up to 650 kg/h in sawdust pellet production and up to 700 kg/h in feed pelletizing.

4. Extended calibrator–cooler for granulate/pellet KC-200:

This device serves as additional product cooling, since the pellet heats up during pelleting. It also removes dust and fine crumbs using a special drum. Power consumption: 0.12 kW.

5. Closed SO-2 extraction system:

Thanks to a fan, this unit ensures the air circulation necessary for cooling the granules and collects leftover material and dust into containers/bags mounted on the frame. Power: 1.5 kW.

6. Control panel:

Compact size and built-in automation cooling make the control panel reliable and easy to install near the production line. The panel is equipped with an ammeter and thermal protection for each motor in the line.

The belt conveyor is not included in the set.

Cables for connecting the line are also not included.

LDG-4000 MAX+ Pellet Production Line Performance:

- wood waste – up to 650 kg/h,

- straw – up to 550 kg/h,

- feed – up to 700 kg/h,

- sunflower husk – up to 550 kg/h.

Optimal performance is achieved with proper particle size and moisture content of the input material.

LDG-4000 MAX+ line types:

Several configurations of the LDG-4000 MAX+ line are available, differing in automation level and additional components such as conveyors, shredders, dryers, or calibrators. The client can choose a solution best suited to their needs – from a basic version to advanced systems with a full extraction system and modules supporting the granulation process.

The LDG-4000 MAX+ pellet production line can be expanded with additional modules:

PK-2 (conveyor-calibrator), a device for feeding and calibrating raw material, ensuring uniform preparation before the next production stage.

PT-500 (belt conveyor), used for transport and cooling of the material after granulation.

RD-500 (shredder), intended for grinding materials such as straw, hay, shavings and other fibrous materials to the required fraction.

MB-500 (hammer mill), used for grinding wood chips and bark to the fraction suitable for further pelletizing.

Example sets:

1. LDG-4000 MAX+ line

2. LDG-4000 MAX+ 43 kW + PT-500 Belt Conveyor with fans

3. LDG-4000 MAX+ line with calibration bunker (equipped with a mesh to filter out bark, pieces of wood, branches, debris) 43 kW + PT-500 Belt Conveyor with fans

4. LDG-4000 MAX+ 43 kW + PT-500 Belt Conveyor with fans + RD-500 Shredder (table included free)

5. LDG-4000 MAX+ 43 kW + PT-500 Belt Conveyor with fans + RD-500 Shredder (table included free) + PT-1000 Belt Conveyor-Calibrator.

Main advantages of the LDG-4000 MAX+ pellet production line:

- High performance – up to 700 kg of feed or 650 kg of pellets per hour

- Versatility – granulation of wood, straw, grains, husks, biomass and plastics

- Large PS-1500 feeder-cyclone ensuring cleanliness and smooth feeding

- Expandable and adaptable to individual customer needs

- Control panel with full safety systems

- Compact dimensions, suitable even for smaller halls

- Eco-friendly solution – maximum utilization of waste

Stable and safe operation thanks to control of each motor section

What raw materials can be used to produce pellets?

- sawdust from deciduous and coniferous trees,

- waste after cleaning sunflower, corn, cereals,

- straw, branches, seed husks,

- waste from plastics production.

What raw materials can be used for feed production?

- grain and cereals,

- meal, hay,

- feed mixtures.

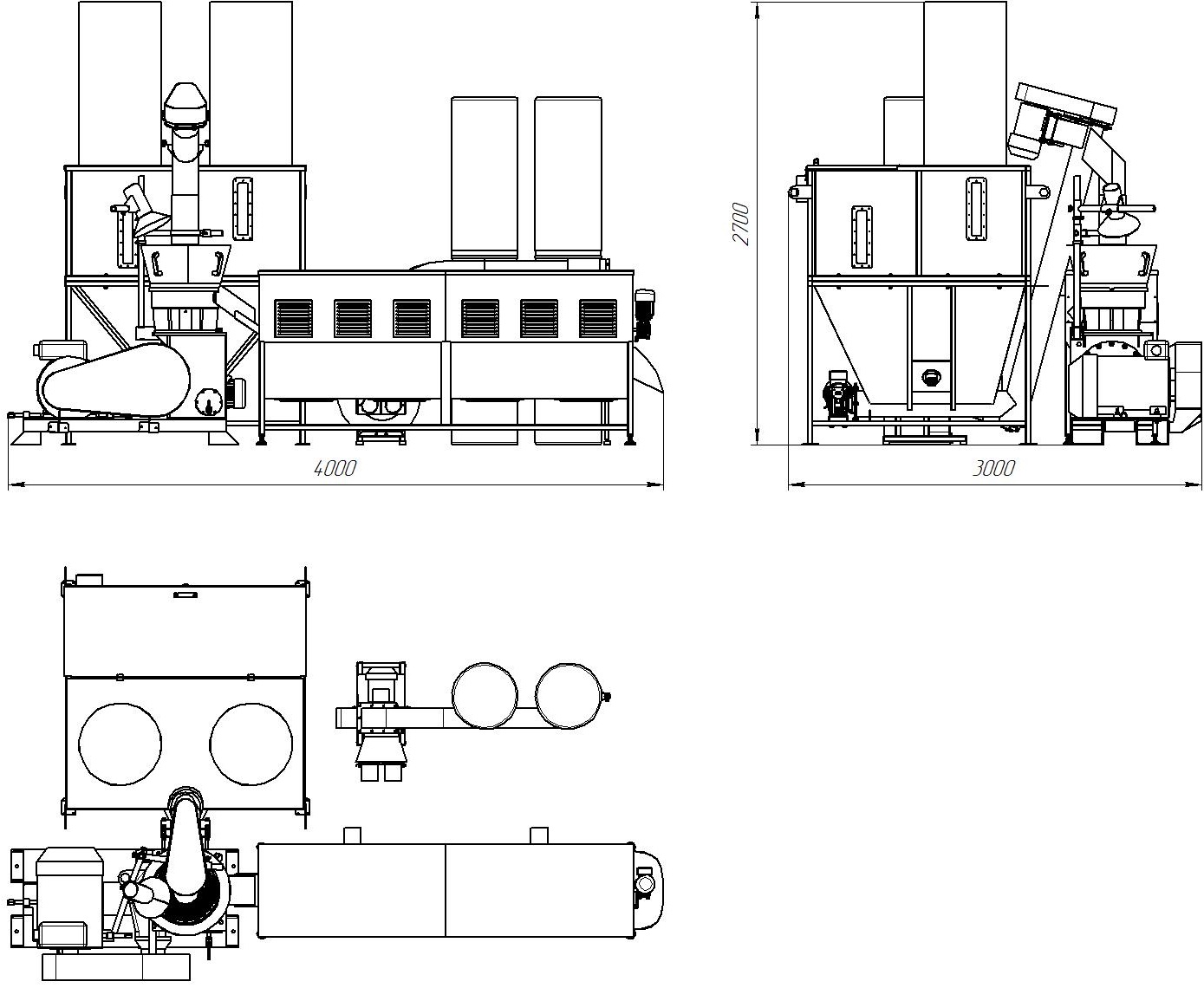

Technical drawing:

End products that can be obtained with the LDG-4000 (MAX+) line:

- Pellet from sawdust, shavings, and wood chips,

- Pellet from plant biomass,

- Fuel pellet from organic waste,

- High-quality feed pellet with uptake up to 90%,

- Plastic granulate, used among others for the production of pipes and technical components.

Technical support and training

With the delivery we provide professional technical support, assistance with installation and start-up, as well as training for your staff. This ensures proper operation of the device and maximum efficiency in everyday work.

Applications

LDG‑4000 MAX+ pellet line is used in many industries, including: fuel pellet production from sawdust, wood chips, and wood waste, granulation of straw and agricultural biomass, production of compound animal feeds, recycling of organic and plastic waste. Pellet production lines from the LDG series guarantee efficiency, versatility, and savings – a reliable solution for companies seeking proven technology for biomass and feed granulation.

The LDG-4000 (MAX+) line can be used even in a small room, which significantly reduces investment costs and expenditure related to renting or purchasing a production hall.

We also offer spare parts, including sets of dies with holes 2 mm, 3 mm, 4 mm, 5 mm, 6 mm and 8 mm,

enabling the production of pellets of various diameters, depending on the type of raw material and the intended product.

Need more information about this device?

Contact us – we’ll advise you on the best solution!

Contact us