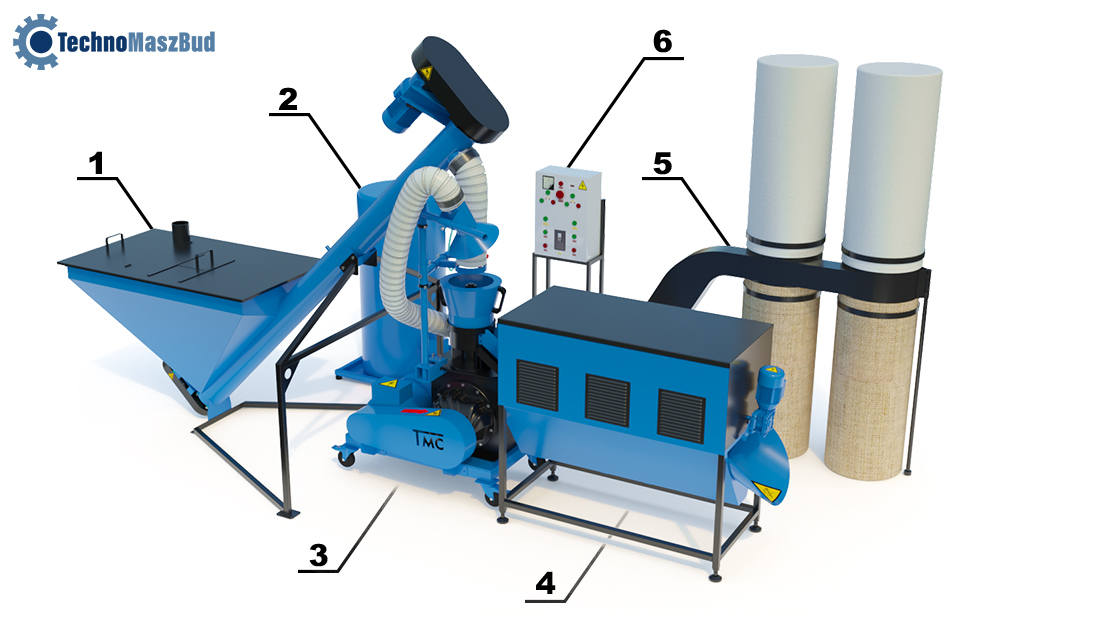

Pellet production Line LDG-2000 (KOMBI)

Available Options

- Product Code: LDG-2000_KOMBI

Description

The LDG-2000 KOMBI pellet and feed production line from TechnoMaszBud, based on the PRIME-200 pelletizer, is an efficient and versatile technological line designed for the production of heating pellets and granulated animal feed.

This device was created for farms, feed mills, carpentry shops, and sawmills looking for efficient and economical solutions for processing wood waste and biomass.

This line differs from the LDG-3000 KOMBI model with a smaller pelletizer with a power of 11 kW. The granulation line can serve as equipment for the production of pellets and granulated feed, both for personal use and for business purposes.

YOU CAN TEST THIS MACHINE WITH YOUR RAW MATERIAL AT OUR WAREHOUSE!

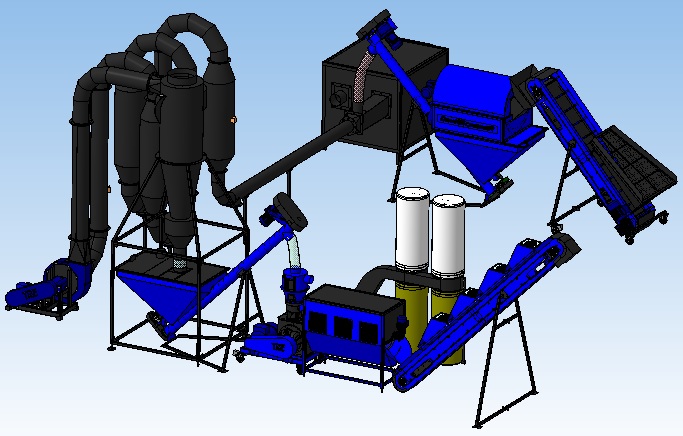

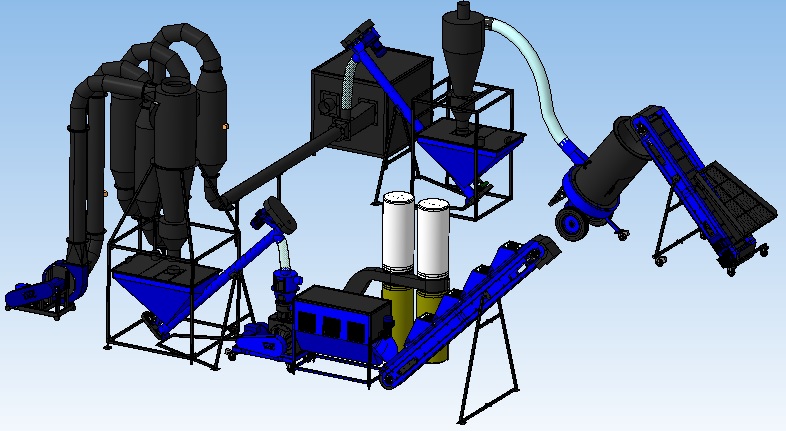

The high efficiency and reliability of the line is ensured by the cooperation of several key components – the auger feeder, moisturizing system, PRIME-200 pelletizer, cooler, extraction system, and integrated control panel. Thanks to this, the complete LDG-2000 KOMBI line is characterized by stable operation, simple maintenance, and the ability to work with many different raw materials.

For your convenience, we can not only select a line tailored to your requirements, but also help with its installation, commissioning, and achieving your expected results!

Video: LDG-2000 KOMBI PRO Pellet Production Line | 18 kW, up to 220 kg/h.

Video: How it works | Efficiency test. LDG-3000 KOMBI Pellet Production Line with Dryer:

Video: Universal Mini Line for Pellet and Feed Production:

The LDG-2000 KOMBI line consists of:

This unit consumes 1.5 kW of electric power and features smooth feed rate adjustment thanks to a frequency converter.

2. Moisturizing System:

The main components of the moisturizing system are: a valve, pump, 100-liter water tank, and nozzle. The system is attached to a rack above the working section, which allows for precise addition of the right amount of moisture during granulation. Power consumption is 0.37 kW.

3. Reliable PRIME-200 Pelletizer:

The PRIME-200 granulator easily handles various types of raw materials at a capacity of up to 150 kg/hour for sawdust pellets and up to 350 kg/hour for feed granules. Moving rollers ensure high durability and reliable operation.

4. Calibrator - Pellet/Granule Cooler KC-100:

This unit is responsible for additional cooling of finished granules, and removing dust and crumbs. This unit uses 0.12 kW.

5. Closed Extraction System SO-2:

This device, using a fan, ensures air circulation necessary to cool the granules and collect calibrated raw material remnants and dust in the bags mounted on it. Power – 1.5 kW.

6. Control Panel:

Small dimensions and a built-in automation cooling system make the control panel reliable and convenient to install near the production line. The panel includes an ammeter and thermal protection for every motor on the line.

The belt conveyor is not included in the set!

Cables for connecting the line are not included in the set

Video: Pellet Production Line | How it works, what it's made of:

Video: How to work on an LDG pellet production line:

Performance of the LDG-2000 KOMBI Pellet Production Line:

- wood waste – up to 150 kg/h;

- straw – up to 150 kg/h;

- feed – up to 350 kg/h;

- sunflower husks – up to 150 kg/h;

The most important thing is to meet the particle size and moisture level requirements for processed raw materials.

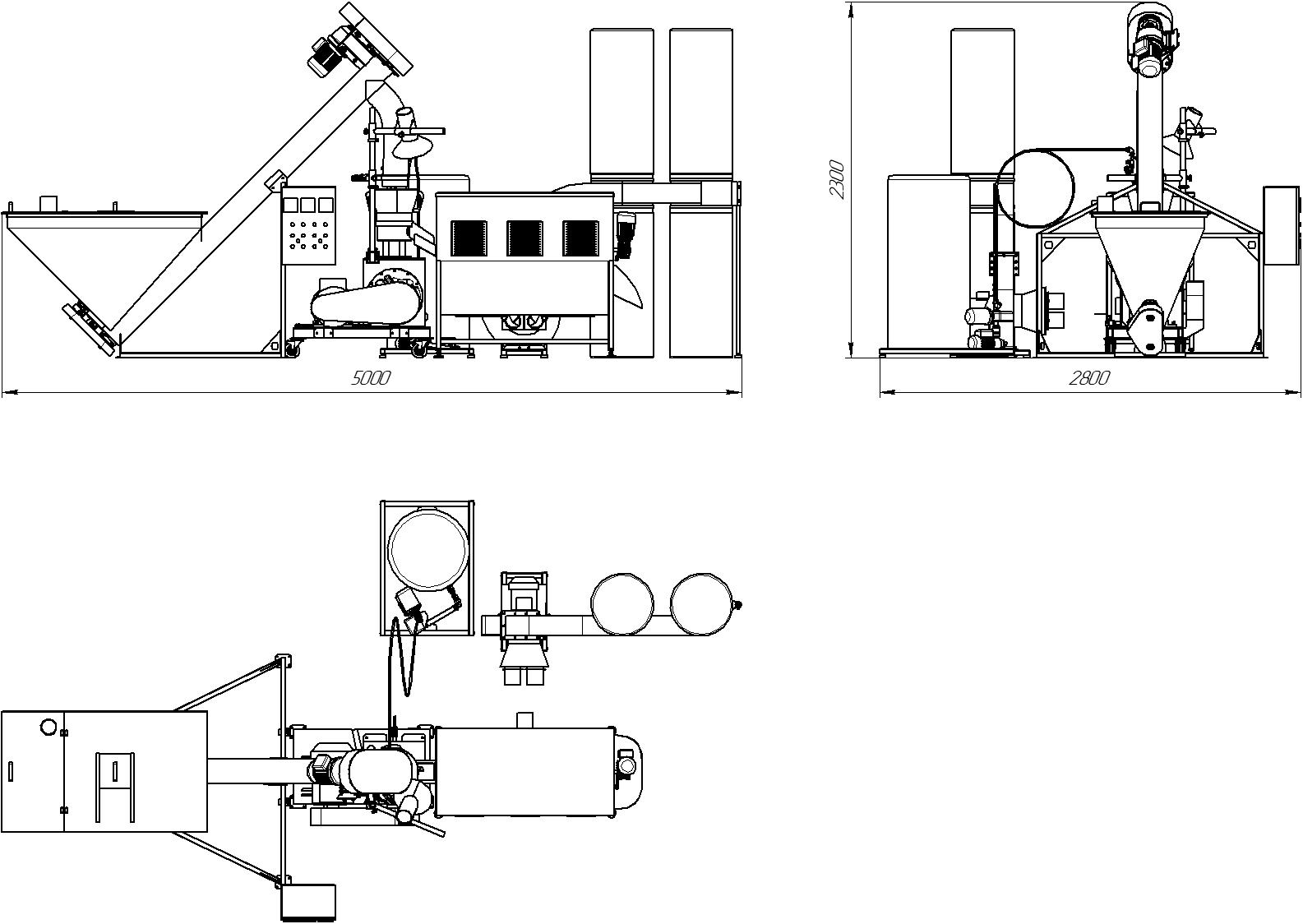

Technical drawing:

Advantages of the LDG-2000 KOMBI line

- High efficiency – up to 350 kg of feed or 150 kg of pellets per hour.

- Integrated and compact design – all components cooperate in one line, making installation and operation simple.

- Raw material versatility – the line processes sawdust, chips, straw, husks, grains, agricultural waste, and even plastics.

- Energy efficiency – optimized motor operation allows reducing energy consumption.

- Personalization – possible to expand with additional equipment e.g., belt conveyors, shredders, or dryers.

- Work safety – safety systems and solid construction ensure reliability and stable operation.

- Economy and ecology – efficient use of wood and agricultural waste reduces costs and provides an additional source of income.

The granulation line can be used as a standalone production system or equipped with additional equipment, making pellet and feed granule production more automated:

PK-2 (conveyor-calibrator), main task: feeding and calibrating raw materials;

PT-250 (belt conveyor), main task: feeding and cooling raw material;

PT-500 (belt conveyor), main task: feeding and cooling raw material;

RD-500 (shredder), main task: grinding raw materials (straw, hay, chips, etc.) to desired size;

KPS-400 (calibrator-feeder), main task: calibrating raw material and smooth feeding;

KC-200 (extended calibrator-cooler), main task: cooling and calibrating finished granules;

SA-400 (aerodynamic dryer with calibrator), main task: calibrating and drying raw material.

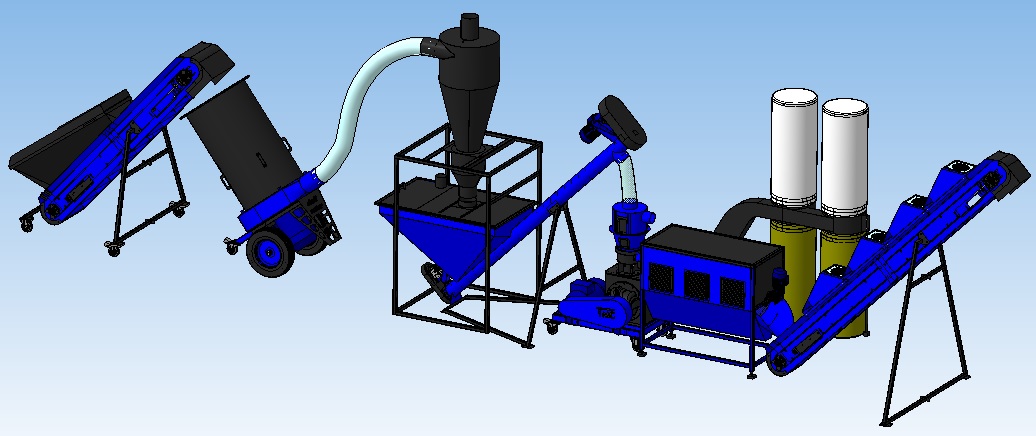

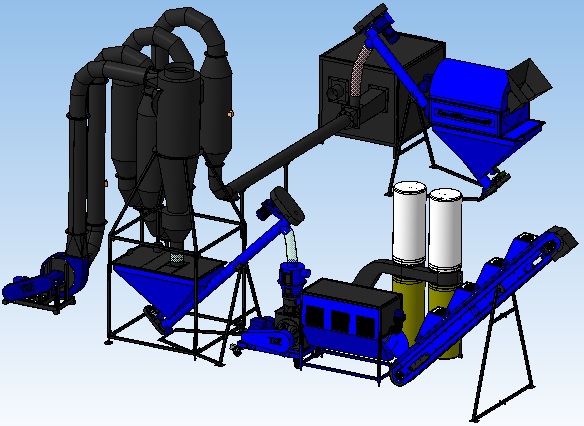

Possible LDG-2000 KOMBI pellet line configurations:

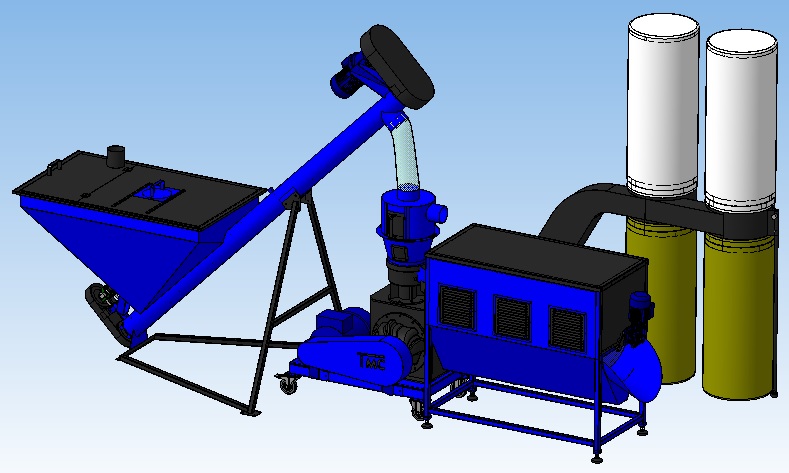

1. LDG-2000 KOMBI line, 14 kW

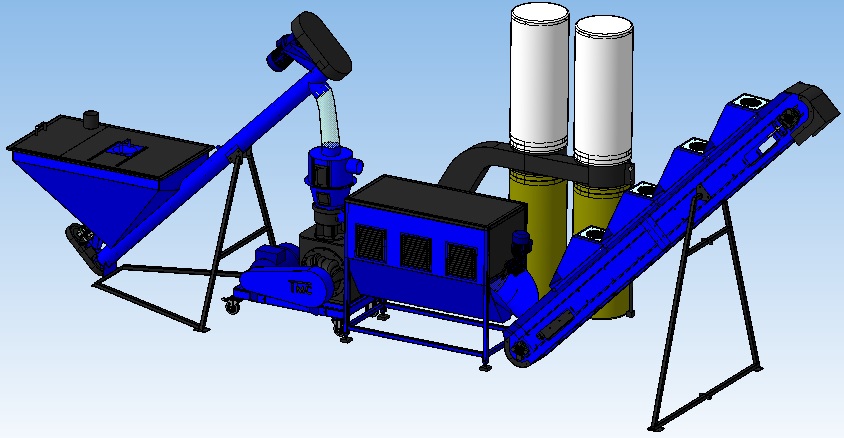

2. LDG-2000 KOMBI line + PT-500 Belt Conveyor with Fans

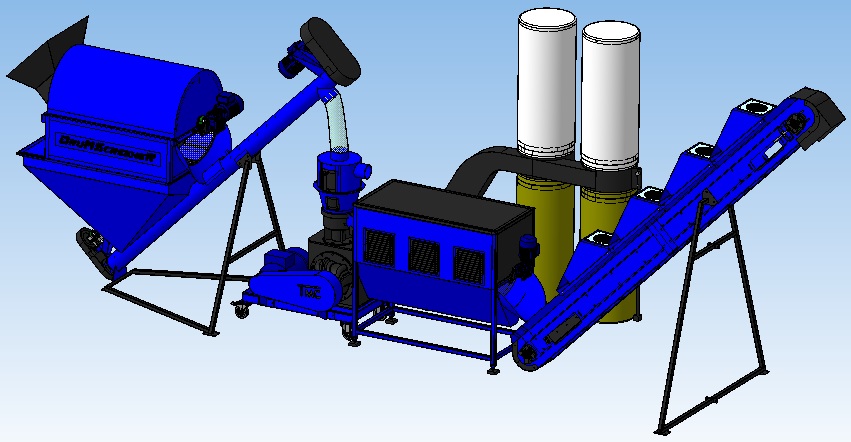

3. LDG-2000 KOMBI line with calibrator (Large fraction separator, which screens out branches, bark, thick pieces of wood, and stones) + PT-500 Belt Conveyor with Fans

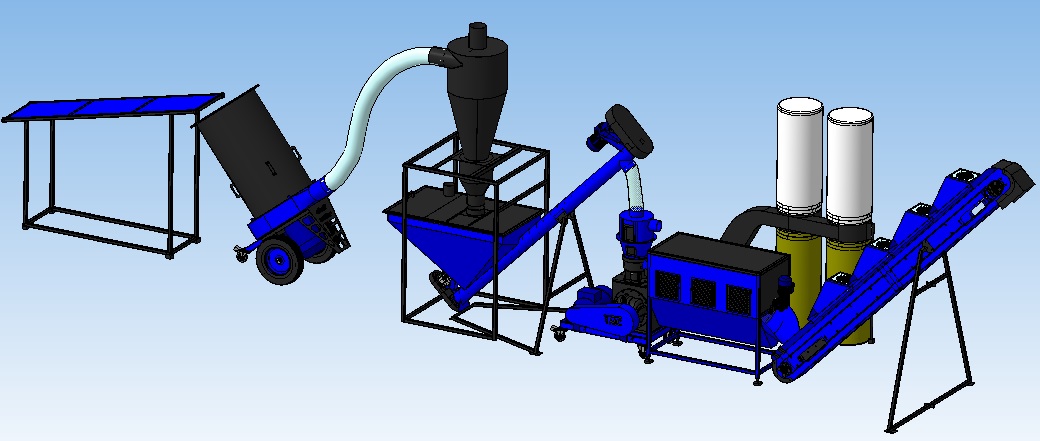

4. LDG-2000 KOMBI line + PT-500 Belt Conveyor with Fans + RD-500 Shredder with cyclone

5. LDG-2000 KOMBI line + PT-500 Belt Conveyor with Fans + RD-500 Shredder with cyclone + Belt calibrator-feeder PT-1000

6. LDG-2000 KOMBI line + PT-500 Belt Conveyor with Fans + SA-400 Aerodynamic Sawdust Dryer

7. LDG-2000 KOMBI line + PT-500 Belt Conveyor with Fans + SA-400 Aerodynamic Sawdust Dryer + Belt calibrator-feeder PT-1000

8. LDG-2000 KOMBI line+ PT-500 Belt Conveyor with Fans + RD-500 Shredder with cyclone + Belt calibrator-feeder PT-1000 + SA-400 Aerodynamic Sawdust Dryer

What raw materials can be processed on the LDG-2000 line?

The LDG-2000 pellet production line is suitable for pelletizing sawdust, chips, dust, straw, peat, plastic, and more. To obtain animal feed granules you can use materials such as grain, grain waste, feed, hay, and meal.

For best pellet quality and satisfactory output, the ideal fraction size is less than 6 mm.

Technical parameters LDG-2000 (KOMBI)

Total power – 14 kW

Dimensions – 500х280х230 cm

Weight – 750 kg.

This line can be installed even in small rooms, which further reduces purchase or rental costs. In addition, spare parts for the equipment can be ordered from us – for example, a set of dies with holes of 2mm, 3mm, 4mm, 5mm, 6mm, and 8mm. This allows you to produce granules of various sizes.

Technical support and training

With delivery, we provide professional technical support, assistance in installation and commissioning, as well as staff training. Thanks to this, the user can be sure of the proper operation of the device and maximum efficiency in everyday use.

Application

LDG-2000 KOMBI line has a wide range of applications in farms, sawmills, carpentry shops, feed plants, and companies engaged in biofuel production.

This model allows for the production of:

- heating pellets from sawdust, chips, wood pieces, and biomass,

- granulated animal feed of homogeneous structure and high digestibility,

- plastic granules used e.g. in pipe production.

Thanks to its versatility and compact design, the LDG-2000 KOMBI is the perfect solution both for your own production needs and for a business focused on selling pellets and granulated feed.

Video: Pellet production from wood chips | 25 kW Line + Dryer:

Video: Straw granulation line | Full pelletizing cycle from bale to packaging:

Need more information about this device?

Contact us – we'll advise you on the best solution!

Contact us