Pellet production line LDG-2000 KOMBI PRO

- Product Code: LDG-2000_KOMBI_PRO

Description

LDG-2000 KOMBI PRO Production Line is an efficient, modern, and versatile technological line designed for the production of heating pellets and granulated animal feed.

The device was created for farms, feed mills, and carpentry and sawmill businesses looking for efficient and economical solutions for processing wood waste, biomass, and agricultural raw materials.

High efficiency and reliability of the line are ensured by the cooperation of several key components – screw feeder, humidification system, PRIME-200 PRO pellet mill, cooler, extraction system, and integrated control panel.

Thanks to the use of a more powerful PRIME-200 PRO granulator compared to the LDG-2000 KOMBI line, the LDG-2000 KOMBI PRO line achieves even greater work stability and higher efficiency, while maintaining simple operation and versatility in processing various raw materials.

YOU CAN TEST THIS MACHINE USING YOUR RAW MATERIAL AT OUR WAREHOUSE!

Main stages of the granulation process:

- Raw material preparation – grinding, drying or mixing.

- Granulation – pellet formation using the pelletizer.

- Cooling and drying – stabilization of pellet shape.

- Sorting and packaging – separating fractions, packaging products.

The heart of the line is the modern PRIME-200 PRO granulator, which, after many hours of testing, implementation, and improvements, achieves capacity of up to 220 kg of pellets per hour. Thanks to its 15 kW motor and rollers with a diameter of 148 mm, the device operates steadily, ensuring constant efficiency!

The granulator is equipped with a 216 mm diameter die. One die is included as standard – the buyer chooses the hole diameter from available variants of 6 mm and 8 mm with various thicknesses, to suit the raw material.

Thanks to the powerful motor and efficient rollers, the PRIME-200 PRO efficiently presses both coniferous and deciduous sawdust. Pine sawdust, rich in lignin (a natural binder), pellets easily. However, the PRIME-200 PRO generates such high pressure that it also presses deciduous sawdust, which contains much less lignin, without any problem.

Moreover, the PRIME-200 PRO granulator also allows pelletizing sunflower husks and various types of straw. All you need is the appropriate set of dies – separate for feed and for heating pellets.

The LDG-2000 KOMBI PRO model features a compact 15 kW pellet mill and a smaller KC-100 calibrator, making it an ideal solution for smaller plants and farms. It works perfectly for both heating pellet and feed production – for in-house use and for commercial purposes.

Need comprehensive support? We provide optimal configuration selection, assistance with installation and start-up, and help in achieving maximum results from your production line!

Video: LDG-2000 KOMBI PRO Pellet Production Line | 18 kW, up to 220 kg/h.

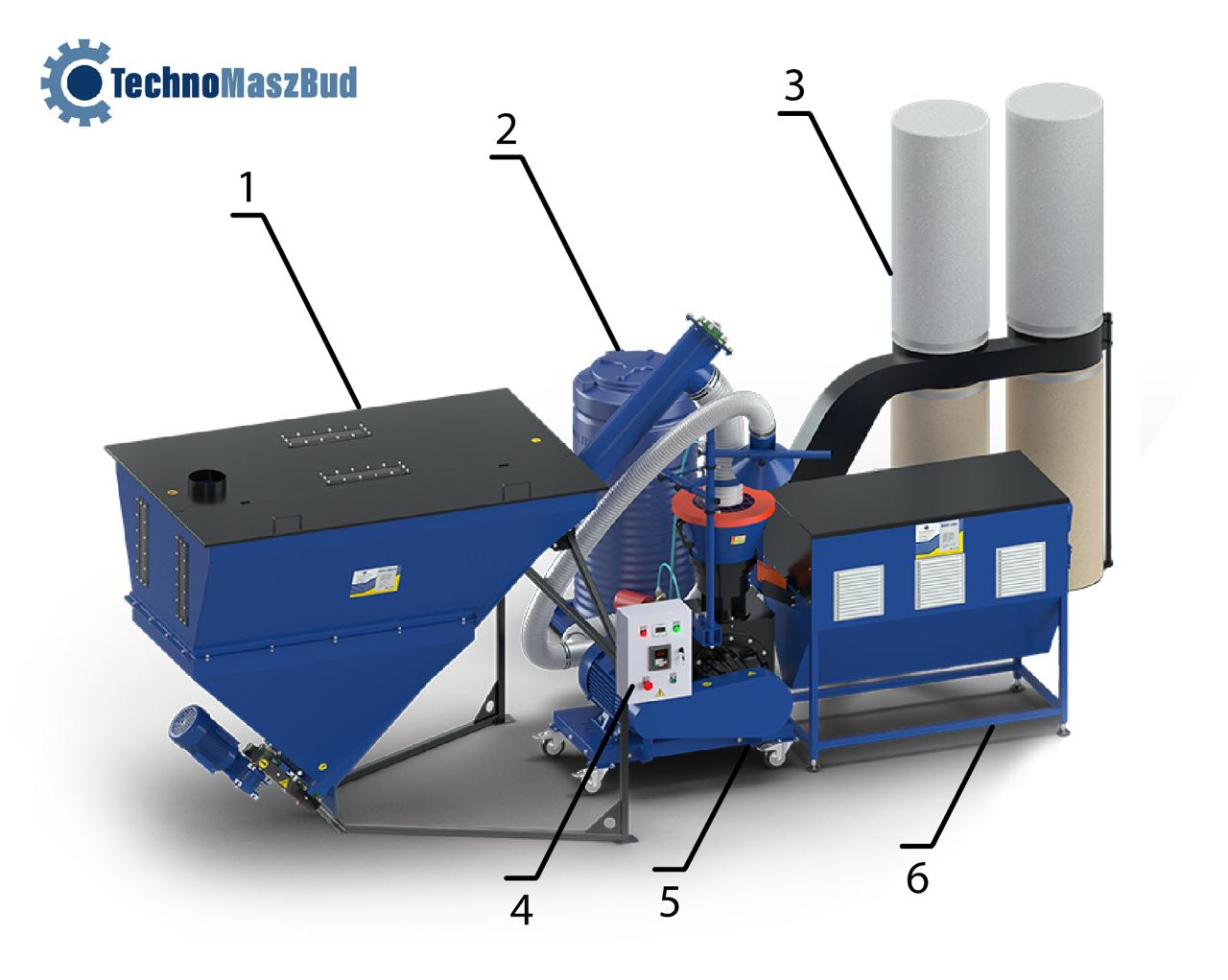

The LDG-2000 KOMBI PRO line consists of:

- Screw Feeder PS-200 PRO (1.5 kW) – smooth adjustment of feed rate thanks to an inverter.

- Humidification system (0.37 kW) – 100 l tank, valve, pump, and nozzle enable precise moisture addition during granulation.

- Closed extraction system SO-2 (1.5 kW) – fan provides air circulation and dust removal to collection bags.

- Control panel – compact, with ammeters and thermal protection for each motor; ensures full control over the production process.

- PRIME-200 PRO Pelletizer (15 kW) – modern granulator with output up to 220 kg/h (pellet) and up to 400 kg/h (feed). Moving rollers, 148 mm in diameter, provide high pressing pressure and process reliability.

- Calibrator-Cooler KC-100 (0.12 kW) – additional cooling of finished pellets, removal of dust and fines.

- 15 kW inverter – provides soft start, speed control, overload protection, and energy savings, thus increasing the safety, longevity, and efficiency of the machine.

* Belt conveyor and connection cables are not included in the set.

Video: Pellet production line | How it works and what it consists of

Video: How to work with the LDG series pellet production line

LDG-2000 KOMBI PRO pellet production line enables processing of various types of raw materials:

- wood waste (sawdust) – up to 220 kg/h,

- straw – up to 220 kg/h,

- feed – up to 350 kg/h,

- sunflower husk – up to 150 kg/h.

It is most important to maintain the correct particle size and moisture content of the processed material.

The LDG-2000 KOMBI PRO line can operate as an independent production unit or be expanded with additional devices to increase automation and efficiency of pellet and feed production.

Technical drawing:

.jpg)

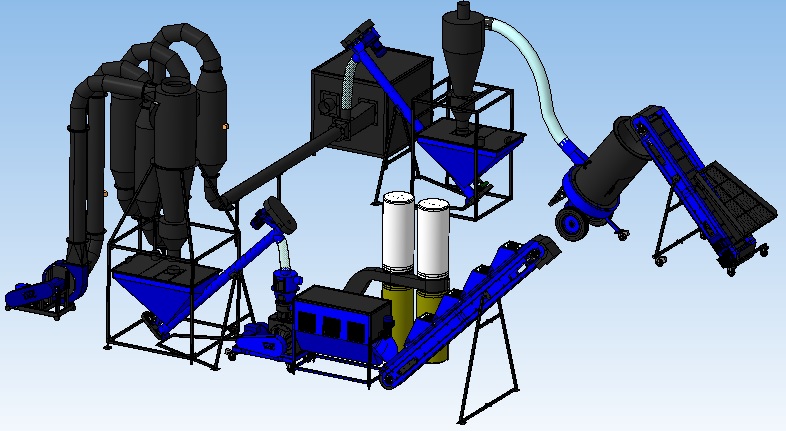

The LDG-2000 KOMBI PRO line can be supplemented with:

- PK-2 (conveyor-calibrator)– conveying and calibration of raw materials,

- PT-250 (belt conveyor)– conveying and cooling the material,

- PT-500 (belt conveyor)– conveying and cooling the material,

- RD-500 (shredder)– grinding straw, hay, chips to the required fraction,

- KPS-400 (calibrator-feeder)– calibration and even feeding of the material,

- KC-200 (extended calibrator-cooler) – cooling and calibration of finished pellets,

- SA-400 (aerodynamic dryer with calibrator)– drying and calibration of material.

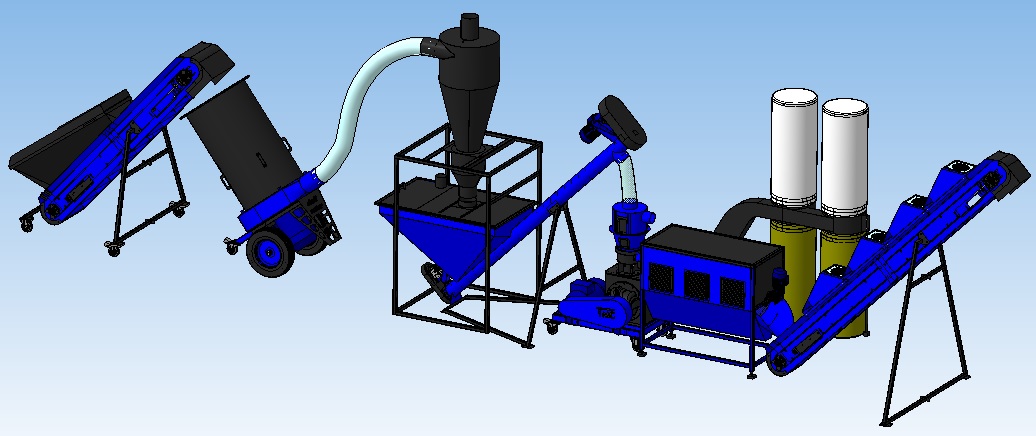

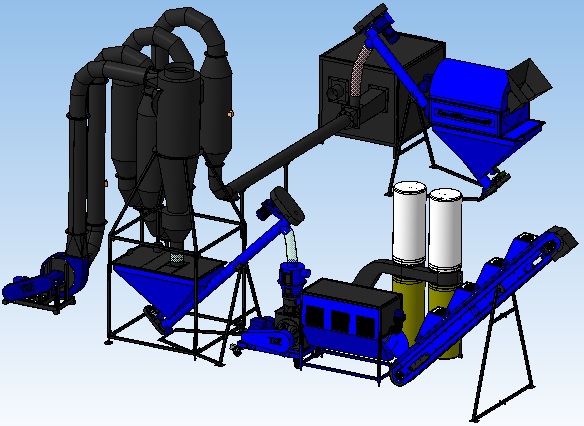

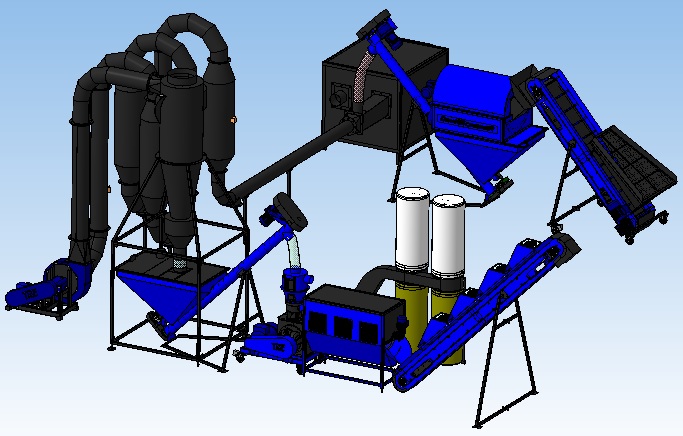

Possible configurations of the LDG-2000 KOMBI PRO line:

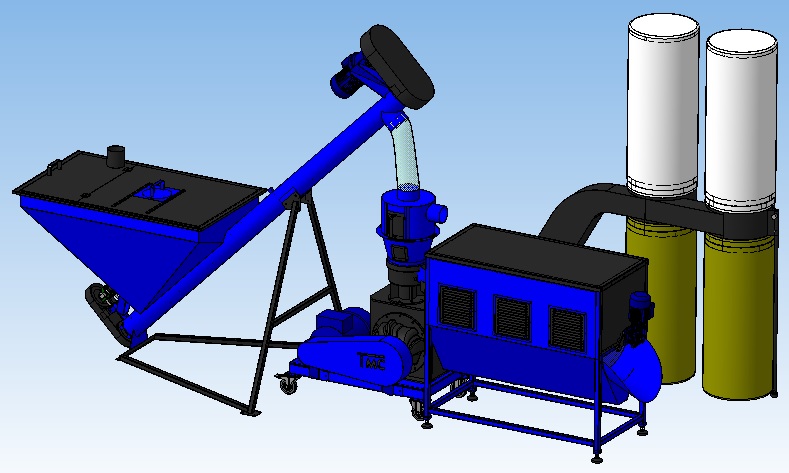

1. LDG-2000 KOMBI PRO line

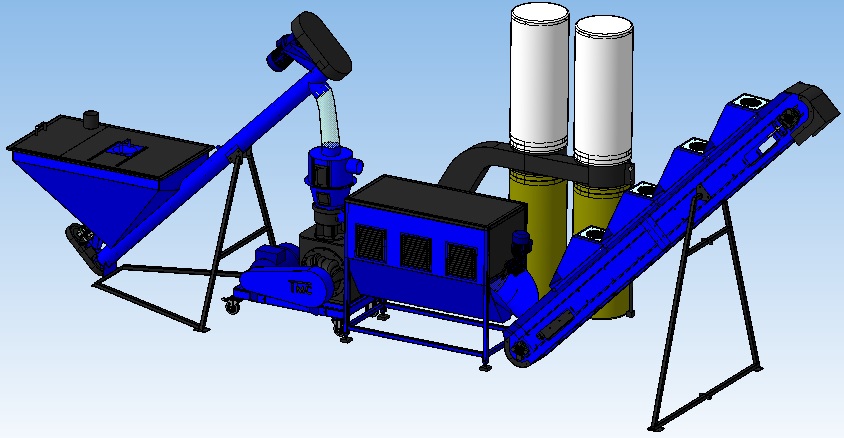

2. LDG-2000 KOMBI PRO line + Belt conveyor PT-500 with fans

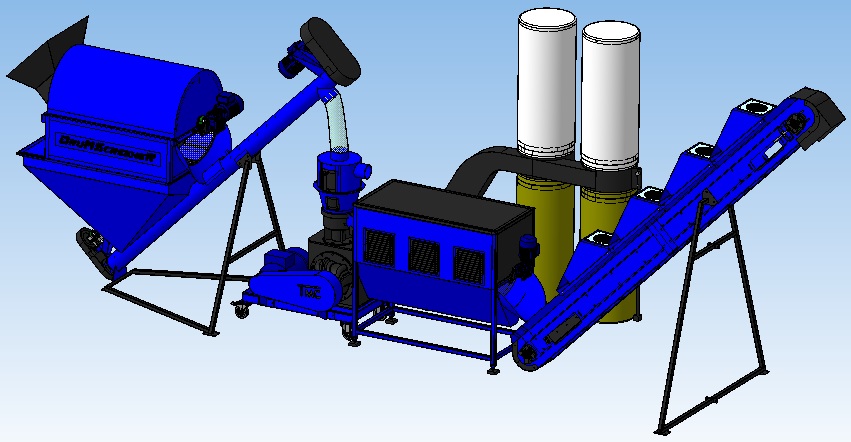

3. LDG-2000 KOMBI PRO line with calibrator (large fraction separator, which screens out branches, bark, larger wood pieces, and stones) + Belt conveyor PT-500 with fans

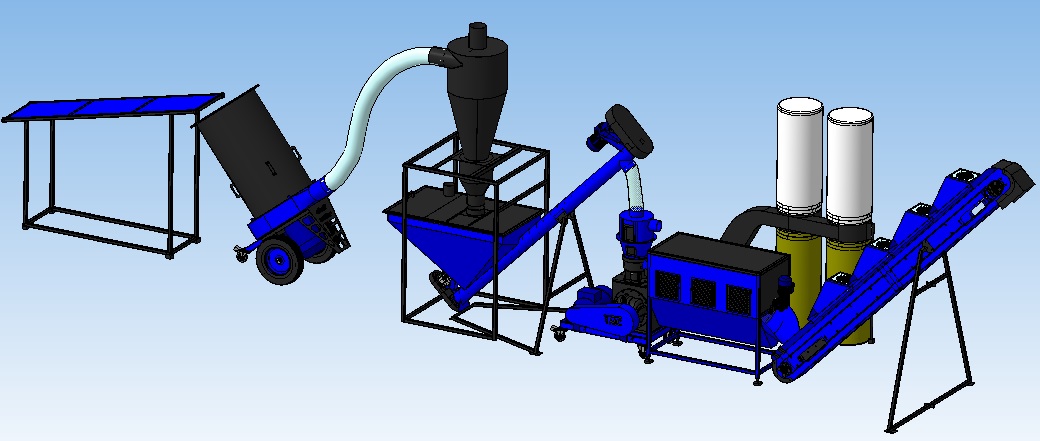

4. LDG-2000 KOMBI PRO line + Belt conveyor PT-500 with fans + Shredder RD-500 with cyclone

5. LDG-2000 KOMBI PRO line + Belt conveyor PT-500 with fans + Shredder RD-500 with cyclone + Belt calibrator-feeder PT-1000

6. LDG-2000 KOMBI PRO line + Belt conveyor PT-500 with fans + Aerodynamic Dryer SA-400

7. LDG-2000 KOMBI PRO line + Belt conveyor PT-500 with fans + Aerodynamic Dryer SA-400 + Belt calibrator-feeder PT-1000

8. LDG-2000 KOMBI PRO line + Belt conveyor PT-500 with fans + Shredder RD-500 with cyclone + Belt calibrator-feeder PT-1000 + Aerodynamic Dryer SA-400

Advantages of the LDG-2000 KOMBI PRO line

- High performance – up to 400 kg of feed or 220 kg of pellets per hour.

- Modern PRIME-200 PRO granulator – higher power (15 kW) and rollers with a diameter of 148 mm allow pressing both soft and harder to granulate raw materials.

- Integrated and compact design – all components work together in one line, simplifying operation and installation.

- Raw material versatility – the line processes sawdust, chips, straw, husks, grains, agricultural waste, and even plastics.

- Energy efficiency – optimized motor operation reduces energy consumption.

- Expandability – the line can be equipped with additional devices: conveyors, shredders, or dryers.

- Safety and reliability – solid construction, moving rollers and safety systems ensure stable operation.

- Economy and ecology – efficient use of wood and agricultural waste reduces costs and generates additional profit.

The set includes a 15 kW inverter for the pelletizer motor, which has several practical justifications:

- Softstart (gentle start-up):

- On start-up, the motor draws very high current (even 6–8 times higher than nominal).

- The inverter limits this current, protecting the electrical installation, fuses, and the motor itself from overload.

- Reduces risk of sudden mechanical shocks to gears and couplings.

- Speed regulation:

- Possibility to match rotational speed to the type of raw material.

- Work optimization — you can find a speed at which the extruder achieves the highest efficiency with minimum energy consumption.

- Easier start-up with heavy loads – starting with low speed, then gradually increasing.

- Operation protection and control:

- The inverter monitors the motor’s current and load — it can stop the machine in case of overload.

- Allows for the connection of protections, automation, and line control.

- Economy and durability:

- Lower energy consumption compared to running at full speed with light loads.

- Extended life of the motor, gearbox, and drive components.

The 15 kW inverter in the pelletizer is an investment in safety, work flexibility and lower operating costs.

Technical support and training

With the delivery, we provide professional technical support, help with installation and start-up, as well as staff training. Thanks to this, the user has confidence in proper operation of the device and maximum productivity in daily work.

Applications of the LDG-2000 KOMBI PRO Line

The LDG-2000 KOMBI PRO line has a wide range of uses in agricultural holdings, sawmills, carpentry workshops, feed mills and companies involved in biofuel production.

This model enables the production of:

- heating pellets from sawdust, chips, wood shavings, and biomass

- granulated animal feed with uniform structure and high digestibility

- plastic granules used i.a. for pipe production

Thanks to its versatility and more powerful pelletizer, LDG-2000 KOMBI PRO is the ideal solution both for your own production needs and for businesses focused on selling pellets and granulated feed.

Video: Pellet production line LDG-2000 KOMBI PRO | 18 kW, up to 220 kg / h.

Video: Pelletizer / granulator PRIME-200 PRO | Performance test on pine sawdust

Video: Universal mini line for pellet and feed production

Need more information about this device?

Contact us – we will advise you on the best solution for your needs!

Contact us