Granulation Line LDG-4000 (DUO) PRO

Available Options

- Product Code: LDG-4000-DUO-PRO

Description

A modern pellet production line with a capacity of up to 1600 kg/h (depending on the type of raw material) was built based on two high-efficiency PRIME-400 PRO pellet mills. It enables both the processing of sawdust and other biomass materials, as well as the production of feed pellets.

The high efficiency of the line is possible thanks to two Prime-400 PRO pelletizers operating simultaneously. Each device is fitted with a 45 kW motor, a die with a diameter of 400 mm, and four movable rollers with a diameter of 178 mm.

One of the key advantages of the LDG-4000 DUO PRO line is the ability to operate continuously even during service or breakdown. Thanks to two PRIME-400 PRO pellet mills, compared to the LDG-3000 DUO PRO line equipped with less efficient PRIME-300 PRO pelletizers, the new LDG-4000 KOMBI PRO model offers even greater operational stability and efficiency while maintaining simple operation and versatility in processing various raw materials.

IT IS POSSIBLE TO TEST THIS MACHINE WITH YOUR MATERIAL AT OUR WAREHOUSE!

A major advantage of the design is the ability to continue production when one of the pellet mills is shut down for maintenance or repair. This solution eliminates downtimes, ensures the continuity of the technological process, and significantly increases both the efficiency and reliability of production, guaranteeing uninterrupted operation of the entire system.

Video: Pelletizer / granulator PRIME-400 PRO | Capacity measurement on pine sawdust:

Video: LDG-3000 DUO pellet line | Production of pellets from pine sawdust:

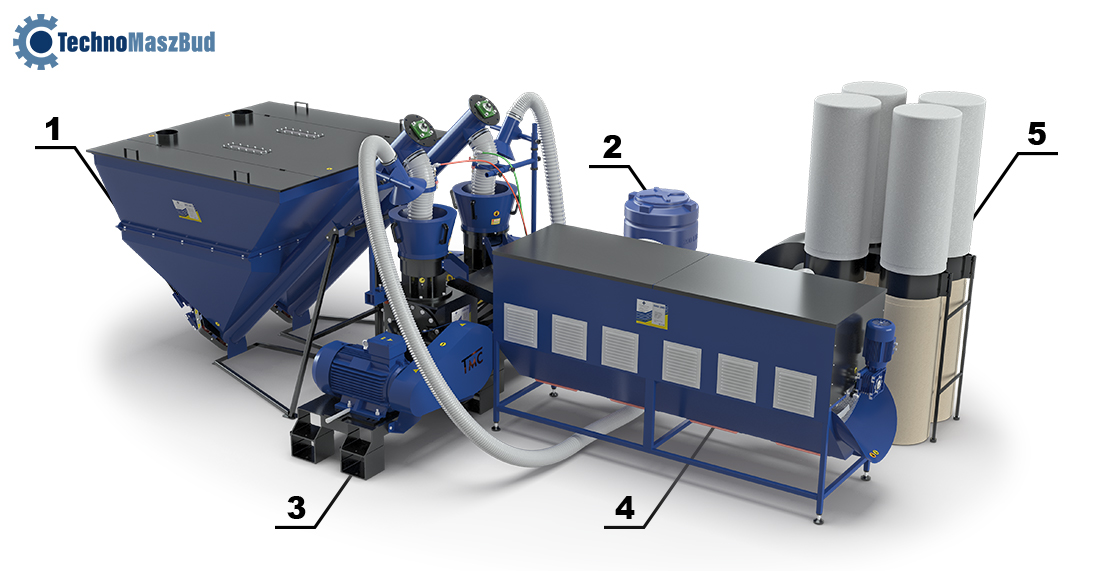

Construction and components of the LDG-4000 DUO PRO line:

1. Screw Conveyor PS-200 DUO PRO:

The conveyor is responsible for storing the raw material and its uniform dosing to the pelletizer. It features smooth feed speed adjustment via a frequency converter. The device's power consumption is 3 kW, and the tank capacity is 2 m³.

2. Moistening system:

The system ensures optimal raw material moisture during pelletizing. It consists of a valve, a pump, a water tank with a capacity of 100 liters, and a nozzle. Power consumption is 0.37 kW.

3. PRIME-400 PRO pellet mills:

Two reliable PRIME-400 PRO pellet mills allow the processing of various raw materials. They achieve actual throughput of up to 1600 kg/h in sawdust pellet production and up to 1400 kg/h for feed pellets.

4. Calibrator – Pellet Cooler KC-300:

Hot pellets, coming directly from the pellet mill, land on the calibration sieve of the rotary drum. As the drum rotates, the pellets are evenly distributed in a thin layer, while at the same time a stream of air generated by the fan passes through the cooling chambers. This process lowers the temperature of the granules, reduces their moisture, and dust and fine fractions are discharged through the lower spouts into the cyclone and onwards to bags.

5. SO-4 closed dedusting system:

The SO-4 system is responsible for removing excess dust and small particles from the cooling and sorting system. Contaminants are collected in filter bags, and air is purified thanks to two upper filters. A key component is a powerful fan ensuring the right pressure for effective dust suction.

6. Control cabinet (control panel):

The control cabinet integrates electrical equipment responsible for automatic control of mechanisms and drives of the line. Compact dimensions and the electronics cooling system make the panel easy to install and very reliable in daily operation.

7. 45 kW inverters (2 pcs):

The inverter provides soft start, speed regulation, overload protection, and energy savings, thus increasing the safety, durability, and efficiency of machine operation.

(Belt conveyor and cables for connecting the line are not included in the set)

Video: Pellet production line LDG-3000 DUO + SA-800 Dryer | Production at a sawmill:

Video: Complete pellet line with capacity up to 800 kg/h | Production from pine sawdust:

Actual capacity of the LDG-4000 DUO line depending on raw material:

- wood waste: up to 1600 kg/h (capacity depends on raw material quality);

- straw: up to 1400 kg/h;

- feed: up to 1400 kg/h.

Achieving optimal pellet production capacity largely depends on maintaining the correct parameters of processed raw materials. Careful selection and appropriate preparation of the input material are key to stable line operation and obtaining a high-quality final product.

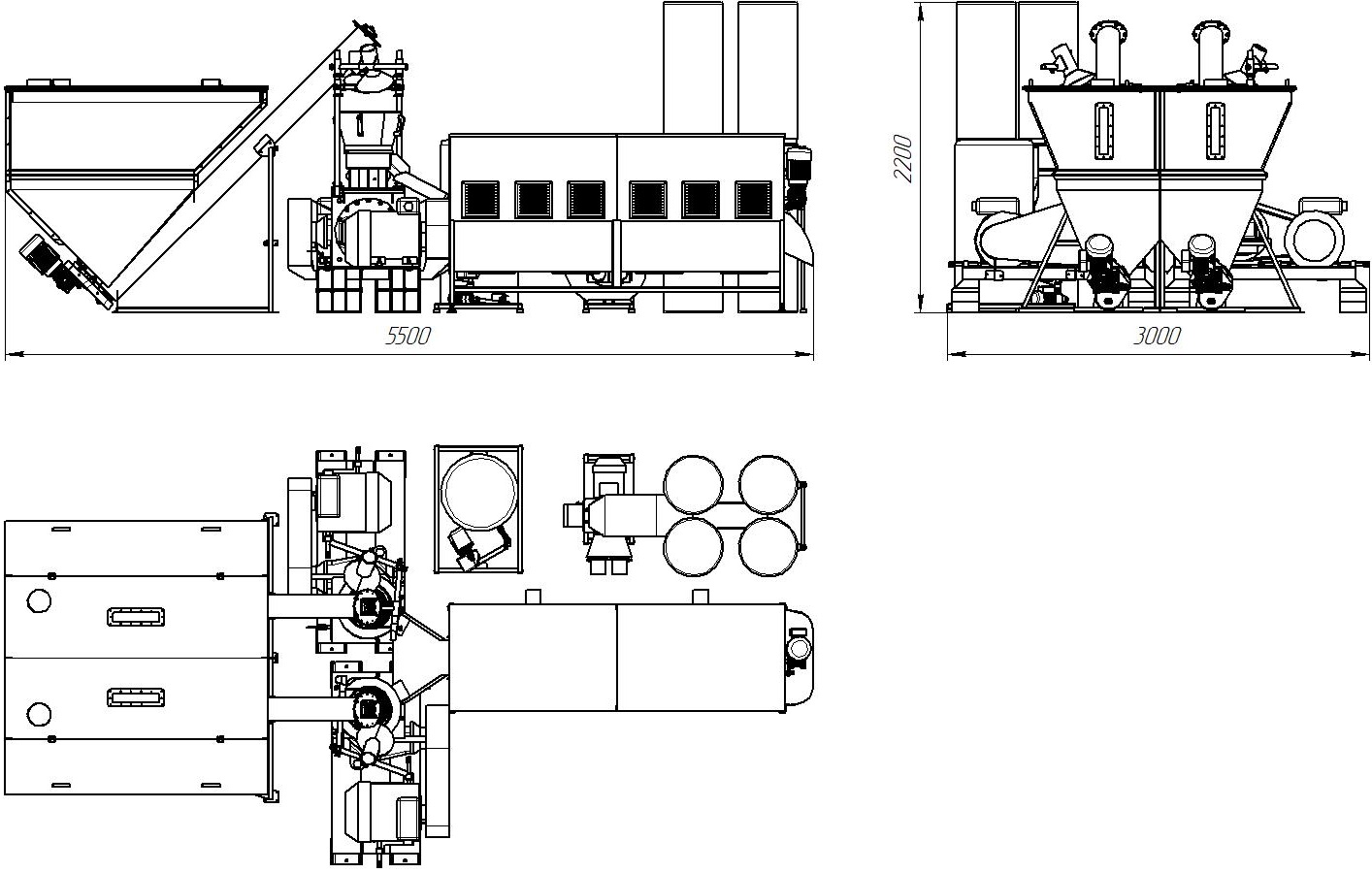

Technical drawing:

The set includes 45 kW inverters for pelletizer motors, which have several practical justifications:

- Softstart (gentle start):

- The motor at startup draws a very high inrush current (up to 6–8 times the nominal).

- The inverter limits this current, protecting the electrical installation, fuses, and the motor itself from overload.

- The risk of sudden mechanical shocks to gears and couplings is reduced.

- Speed regulation:

- Possibility to adjust rotational speed to the type of raw material.

- Work optimization – you can find the speed at which the extruder achieves its highest output with the lowest energy consumption.

- Easier startup under heavy load – first slow speeds, then gradual increase.

- Protection and control of operation:

- The inverter monitors the current and load on the motor – can stop the machine in case of overload.

- Allows interfacing with safety systems, automation, and line control.

- Economy and durability:

- Lower energy consumption compared to operating at full speed with light loads.

- Extended life of the motor, gearbox, and drive components.

A 45 kW inverter in the pellet mill is an investment in safety, work flexibility, and lower operating costs.

Video: Complete LDG-3000 (DUO) pellet line | up to 800 kg/h:

Video: Pellet production line LDG-3000 DUO | Output up to 800 kg/h:

Main advantages of the LDG-4000 DUO PRO pellet production line

High output

Thanks to the use of two PRIME-400 PRO pelletizers, the line achieves capacities of up to 1600 kg/h for wood pellet production and up to 1400 kg/h for feed pelletizing.

Raw material versatility

The machine allows processing a wide range of raw materials such as sawdust, straw, grain cleaning waste, feed mixes, or other plant materials.

Process automation

The use of a moistening system, calibrator-cooler, and closed dedusting system ensures a stable technological process, high pellet quality, and continuous production.

Reliability and durability

High-quality components, precision workmanship, and solid design guarantee long equipment life and trouble-free operation even in intensive working conditions.

Configurations of the LDG-4000 DUO PRO line

The line is available in various configurations which can be adapted to individual production needs. Optional equipment includes, among others:

This solution enables full process automation and increases the efficiency and quality of the final product – both wood pellets and compound feeds.

Technical support and training

With delivery, we provide:

- comprehensive technical support,

- assistance with installation and commissioning,

- staff training on operation and maintenance of the line.

Thanks to this, the user gains confidence in correct operation, maximum production efficiency, and long equipment life.

Applications

The LDG-4000 DUO PRO pellet production line is used in:

- the feed industry,

- agriculture,

- fuel pellet production.

It is the ideal solution for medium-sized production facilities looking for high efficiency, reliability, and flexibility in raw material selection.

Do you need more information about this device?

Contact us – we will advise you on the best solution for your needs!

Contact us